Are you gearing up for an interview for a Broach Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Broach Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

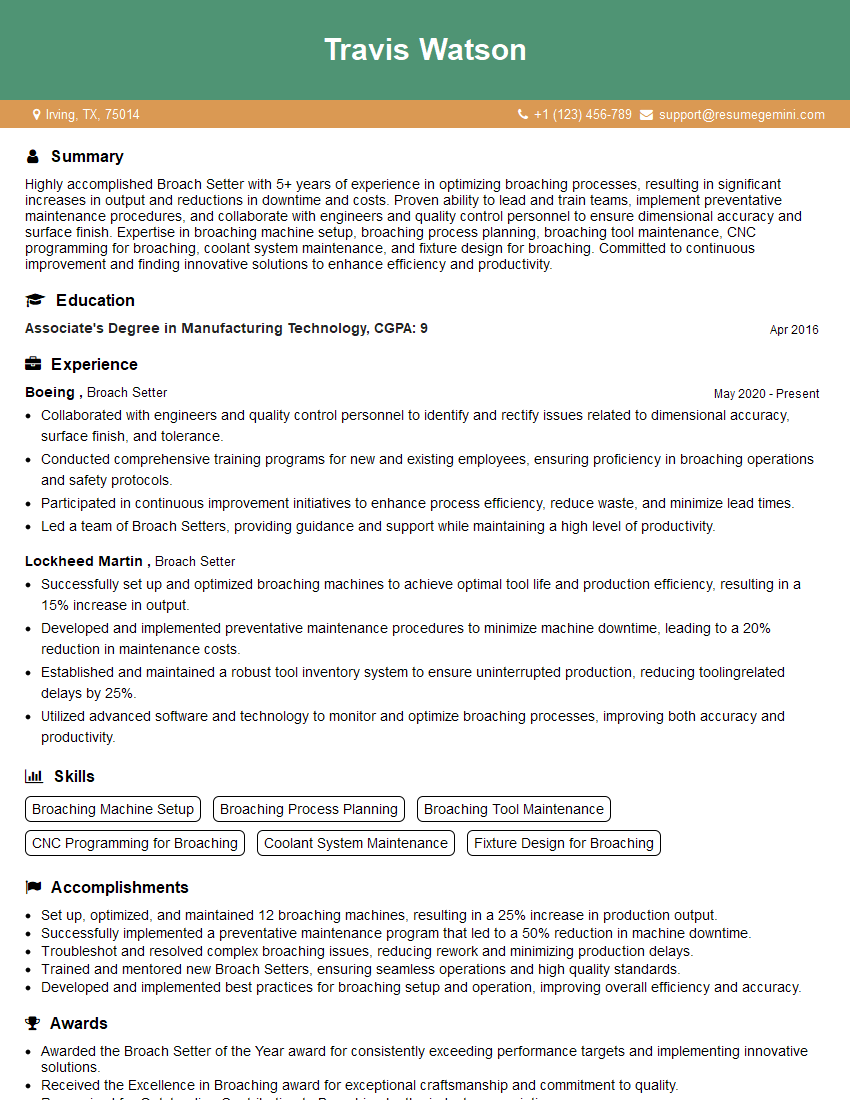

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Broach Setter

1. Describe the key responsibilities of a Broach Setter.

- Set up, adjust, and operate broaching machines to cut slots, holes, and other shapes in metal workpieces.

- Read blueprints and engineering drawings to determine the correct setup and operating parameters for the broaching machine.

- Select and install the appropriate broaching tools, fixtures, and coolants for each job.

- Monitor the broaching process and make adjustments as needed to ensure the workpiece is cut to the correct specifications.

- Inspect the finished workpiece to ensure it meets the required quality standards.

- Maintain and repair broaching machines and tooling to keep them in good working order.

2. Explain the different types of broaching machines and their applications.

- Horizontal broaching machines: Used for broaching internal and external surfaces, such as slots, holes, and keyways.

- Vertical broaching machines: Used for broaching large workpieces, such as castings and forgings.

- Rotary broaching machines: Used for broaching complex shapes, such as gears and splines.

- Continuous broaching machines: Used for high-volume production of small parts, such as pins and bushings.

3. What are the different types of broaching tools and their applications?

- Pull broaches: Used for broaching internal surfaces, such as slots and holes.

- Push broaches: Used for broaching external surfaces, such as keyways and splines.

- Rotary broaches: Used for broaching complex shapes, such as gears and splines.

- Continuous broaches: Used for high-volume production of small parts, such as pins and bushings.

4. How do you select the correct broaching tool for a particular job?

- Consider the type of surface to be broached (internal or external).

- Determine the size and shape of the broached feature.

- Select a broach with the appropriate cutting geometry for the material being broached.

- Choose a broach with the correct shank size to fit the broaching machine.

5. How do you set up a broaching machine?

- Mount the broach in the broaching machine.

- Install the workpiece in the fixture.

- Set the cutting parameters, such as speed, feed, and depth of cut.

- Start the broaching process and monitor it closely.

6. How do you troubleshoot common broaching problems?

- Chatter: Caused by excessive vibration during the broaching process. Can be fixed by adjusting the cutting parameters or by using a different broach.

- Tool breakage: Caused by using a dull or damaged broach, or by cutting too aggressively. Can be fixed by replacing the broach or by adjusting the cutting parameters.

- Poor surface finish: Caused by using a dull or damaged broach, or by cutting too aggressively. Can be fixed by replacing the broach or by adjusting the cutting parameters.

7. How do you maintain a broaching machine?

- Clean the machine regularly to remove chips and debris.

- Lubricate the machine’s moving parts.

- Inspect the machine’s electrical components regularly and make repairs as needed.

- Calibrate the machine’s cutting parameters to ensure accuracy.

8. What are the safety precautions that must be taken when operating a broaching machine?

- Wear appropriate safety gear, such as eye protection, gloves, and earplugs.

- Keep the work area clean and free of clutter.

- Never reach into the broaching machine while it is in operation.

- Be aware of the machine’s pinch points and keep hands clear.

- Follow all manufacturer’s instructions for safe operation.

9. What is your experience with broaching machines?

- I have been working as a Broach Setter for the past 5 years.

- I have experience with a variety of broaching machines, including horizontal, vertical, rotary, and continuous broaching machines.

- I am proficient in setting up, operating, and troubleshooting broaching machines.

- I have a strong understanding of broaching tools and their applications.

- I am committed to safety and always follow all manufacturer’s instructions for safe operation.

10. Why should we hire you as a Broach Setter?

- I have the skills and experience that you are looking for in a Broach Setter.

- I am a hard worker and I am always willing to go the extra mile.

- I am a team player and I am always willing to help out my colleagues.

- I am confident that I can make a valuable contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Broach Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Broach Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Broach Setters are responsible for setting up and operating broaching machines, ensuring that they run efficiently and produce high-quality parts. Their duties include:

1. Set up and operate broaching machines

Broach Setters adjust and align broaching tools, ensuring that they are properly positioned and secured. They also set up and operate the machine, controlling the speed, feed, and depth of cut.

2. Maintain and troubleshoot broaching machines

Broach Setters perform regular maintenance on broaching machines, including lubrication, cleaning, and adjustments. They also troubleshoot and repair any machine problems that may occur, ensuring that the machine is functioning properly.

3. Inspect and measure parts

Broach Setters inspect and measure parts produced by the broaching machine, ensuring that they meet the required specifications. They use precision measuring tools and techniques to verify the dimensions, tolerances, and surface finish of the parts.

4. Work with other production staff

Broach Setters work closely with other production staff, such as machinists and quality inspectors, to ensure that the broaching process is running smoothly. They communicate any issues or concerns to the appropriate personnel and work together to resolve them.

Interview Tips

Preparing for a Broach Setter interview requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the company and the position

Take the time to research the company you’re applying to and the specific Broach Setter position. This will help you understand the company’s culture, products, and services, as well as the specific responsibilities and requirements of the role.

2. Practice your technical skills

Review your knowledge of broaching techniques, machine operation, and inspection procedures. Practice answering technical questions and providing examples of your experience with these skills. You may also want to consider taking a refresher course or reading technical articles to enhance your knowledge.

3. Highlight your attention to detail

Broach Setters must have a keen eye for detail and be able to work with precision. In your interview, emphasize your attention to detail, your ability to follow instructions carefully, and your commitment to producing high-quality parts.

4. Demonstrate your problem-solving skills

Broach Setters often encounter problems with broaching machines or the parts they produce. In your interview, provide examples of how you have solved problems in the past, your ability to think critically, and your willingness to learn from your mistakes.

5. Prepare questions for the interviewer

At the end of the interview, you will likely have the opportunity to ask the interviewer questions. Prepare some thoughtful questions that demonstrate your interest in the company and the position, such as their training programs, safety procedures, or quality control standards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Broach Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.