Are you gearing up for a career in Broaching Machine Set Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Broaching Machine Set Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

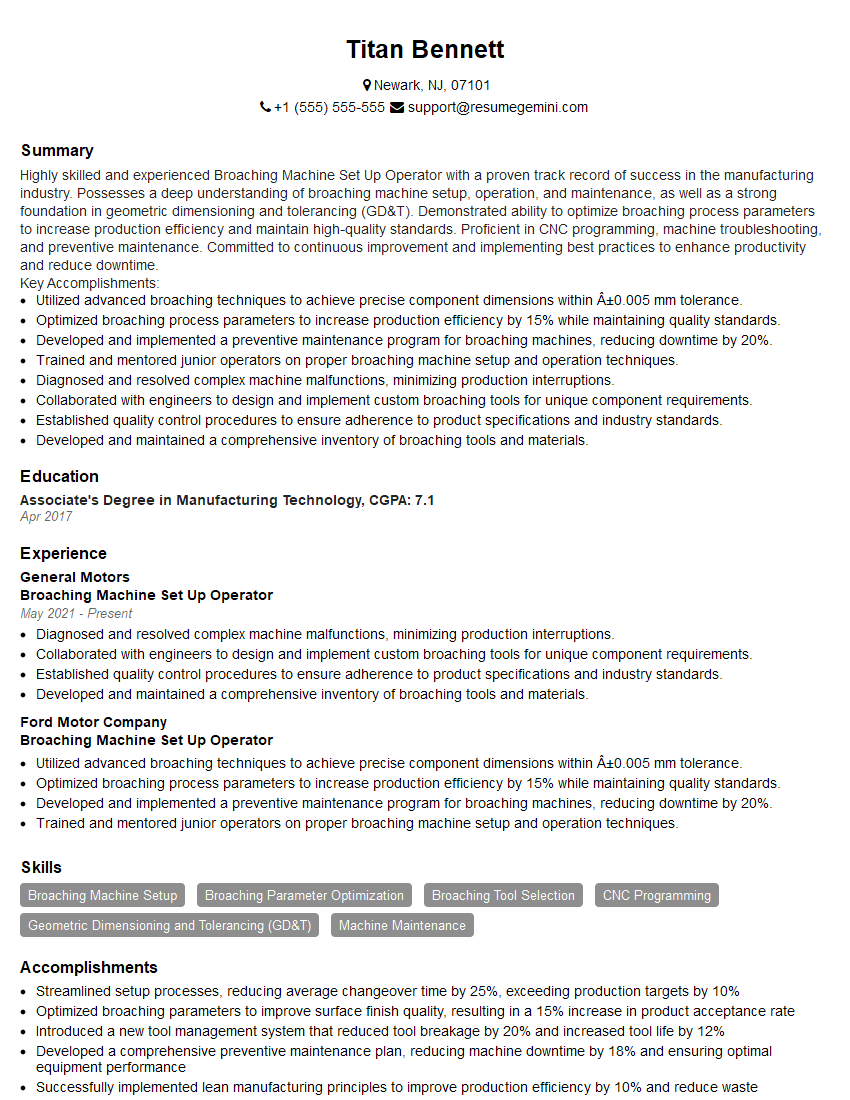

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Broaching Machine Set Up Operator

1. What are the key responsibilities of a Broaching Machine Set Up Operator?

As a Broaching Machine Set Up Operator, my key responsibilities include:

- Setting up and operating broaching machines to produce precise and dimensionally accurate parts.

- Interpreting engineering drawings and specifications to determine machining parameters, tool selection, and cutting speeds.

- Installing and adjusting broaches, workholding fixtures, and cutting tools to ensure optimal performance.

- Establishing and maintaining proper machine settings, including tool offsets, feed rates, and coolant flow.

- Monitoring and inspecting parts during and after machining to ensure quality and adherence to specifications.

2. Can you describe the different types of broaching machines and their applications?

Vertical Broaching Machines

- Used for external and internal broaching operations, where the workpiece is held stationary while the broach moves vertically.

- Suitable for producing parts with straight or simple contours.

Horizontal Broaching Machines

- Designed for high-volume production of parts with complex contours or multiple surfaces.

- Workpiece is moved horizontally while the broach remains stationary.

Rotary Broaching Machines

- Used for machining cylindrical or round workpieces.

- Broach is rotated while the workpiece remains stationary, creating a smooth and accurate surface finish.

3. How do you determine the correct broach type and size for a specific job?

I determine the appropriate broach type and size by considering the following factors:

- Material properties of the workpiece, including hardness and toughness.

- Shape and complexity of the desired features or surfaces.

- Required surface finish and dimensional tolerances.

- Available broach sizes and configurations.

4. What are some common troubleshooting techniques for broaching operations?

When troubleshooting broaching operations, I typically follow these steps:

- Inspect the broach for wear or damage, as this can cause poor surface finish or dimensional inaccuracies.

- Check machine settings, including feed rates, cutting speeds, and coolant flow, to ensure they are optimized for the specific broaching operation.

- Examine the workpiece material and cutting lubricant to ensure they are compatible and not causing excessive tool wear or part defects.

- Analyze the broaching process itself, such as tool approach, pull-out speed, and dwell time, to identify any areas that require adjustment.

5. How do you ensure the safety of yourself and others when operating a broaching machine?

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Inspect the machine and ensure all guards and safety devices are in place and functioning properly.

- Never attempt to operate the machine without proper training and authorization.

- Securely clamp and fixture the workpiece to prevent it from moving or falling during machining.

- Be aware of the machine’s operating area and keep it clear of any obstructions or personnel.

6. Can you explain the process of broaching a keyway?

Preparing the Workpiece

- Mark and drill a hole at the center of the desired keyway.

Selecting the Broach

- Choose a broach with the correct width and depth to match the keyway specifications.

Setting Up the Machine

- Install the broach and secure it in the broaching machine.

- Position the workpiece on the table and align it with the broach.

Broaching the Keyway

- Start the broaching machine and slowly advance the broach into the workpiece.

- Monitor the process closely to ensure the broach is cutting smoothly and producing the desired shape.

7. What are the advantages of using broaching over other machining methods?

- High precision and dimensional accuracy due to the rigid setup and guided cutting action.

- Excellent surface finish and reduced need for secondary finishing operations.

- Increased production speed compared to traditional machining methods, such as milling or shaping.

- Capability to produce complex shapes and profiles that would be difficult to achieve with other methods.

- Suitable for high-volume production runs, offering cost-effectiveness and efficiency.

8. Can you describe the different types of broaching tools?

Solid Broaches

- Made from a single piece of tool steel and offer exceptional durability.

- Suitable for high-volume production of parts with simple shapes.

Inserted Broaches

- Feature replaceable cutting inserts, allowing for cost savings and reduced downtime.

- Versatile and can be used for a wide range of materials and applications.

Round Broaches

- Designed for broaching internal cylindrical surfaces.

- Offer high precision and can produce complex shapes and profiles.

9. What is the importance of coolant in broaching operations?

- Reduces friction and extends tool life by cooling the cutting zone.

- Washes away chips and debris, preventing their accumulation and potential damage to the workpiece.

- Lubricates the cutting surfaces, improving surface finish and reducing tool wear.

- Helps maintain dimensional accuracy by preventing thermal distortion of the workpiece.

10. Can you explain the difference between internal and external broaching?

Internal Broaching

- Involves cutting internal surfaces or holes in the workpiece.

- Uses broaches that are pulled or pushed through the workpiece.

- Commonly used for producing keyways, splines, and internal gears.

External Broaching

- Involves cutting external surfaces or profiles on the workpiece.

- Uses broaches that are pushed or pulled over the workpiece.

- Commonly used for producing flat surfaces, complex contours, and gear teeth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Broaching Machine Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Broaching Machine Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Broaching Machine Set Up Operator is responsible for setting up and operating broaching machines to produce precision parts for various industries. Key job responsibilities include:

1. Machine Setup and Operation

Installing and aligning broaching tools, fixtures, and workpieces on the machine

- Operating the machine to perform broaching operations, including internal, external, surface, and keyway broaching

- Adjusting machine settings, such as speed, feed, and depth of cut, to optimize performance

2. Quality Control

Inspecting and measuring workpieces to ensure they meet specifications

- Using measuring instruments, such as calipers and micrometers, to verify dimensions and tolerances

- Identifying and rectifying any defects or errors in the broaching process

3. Maintenance and Troubleshooting

Performing routine maintenance on the broaching machine, such as lubrication and cleaning

- Troubleshooting and resolving machine malfunctions or breakdowns

- Coordinating with maintenance personnel to ensure optimal machine performance

4. Production and Efficiency

Monitoring and optimizing production processes to improve efficiency

- Analyzing production data to identify areas for improvement

- Implementing process modifications to increase productivity and reduce downtime

Interview Tips

To prepare for an interview as a Broaching Machine Set Up Operator, you should:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and services, as well as the specific requirements of the job.

- Visit the company’s website, read industry news, and connect with current or former employees on LinkedIn.

- Review the job description carefully and identify the key skills and experiences required.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in broaching machine setup and operation, quality control, and troubleshooting.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Prepare examples of projects where you successfully solved problems, improved efficiency, or implemented new processes.

3. Demonstrate Attention to Detail and Problem-Solving Abilities

Broaching Machine Set Up Operators must have strong attention to detail and problem-solving skills.

- Share examples where you identified and resolved errors or defects in the broaching process.

- Explain your problem-solving approach and how you prioritize tasks under pressure.

4. Show Enthusiasm for the Industry and Continuous Improvement

Express your interest in the metalworking industry and your commitment to continuous learning.

- Discuss your knowledge of industry trends and advancements in broaching technology.

- Share your willingness to learn new skills and stay updated on best practices.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Broaching Machine Set Up Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.