Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Broke Beater Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

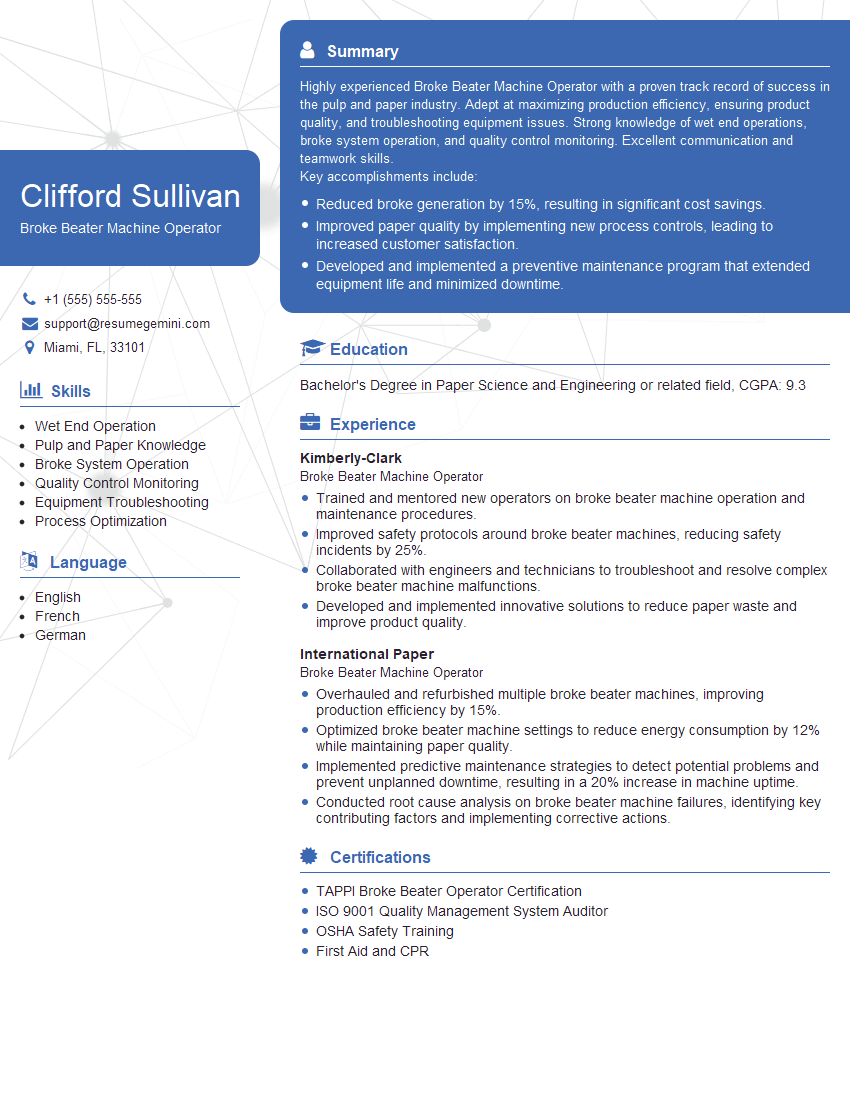

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Broke Beater Machine Operator

1. What are the key responsibilities of a Broke Beater Machine Operator?

- Operate and maintain broke beater machine to process waste paper materials.

- Adjust machine settings and ensure optimal production levels.

- Monitor machine performance, identify and resolve issues.

- Maintain a safe and clean work environment.

- Follow company policies and procedures.

2. How do you ensure the quality of the finished product?

Maintain Machine Calibration

- Regularly calibrate the broke beater machine according to manufacturer specifications.

- Ensure that the machine is operating within the specified tolerances.

Monitor Process Parameters

- Continuously monitor process parameters such as temperature, pressure, and flow rates.

- Adjust parameters as needed to maintain optimal quality.

Inspect Finished Product

- Visually inspect the finished product for defects or inconsistencies.

- Conduct laboratory tests to ensure product meets specifications.

3. What are the common maintenance tasks associated with a broke beater machine?

- Lubricate moving parts to minimize friction and wear.

- Replace worn or damaged components.

- Clean the machine regularly to remove debris and prevent build-up.

- Inspect machine components for signs of damage or wear.

- Follow manufacturer’s recommended maintenance schedule.

4. How do you troubleshoot and resolve common issues with a broke beater machine?

- Identify the problem by observing symptoms and reviewing machine logs.

- Diagnose the root cause by analyzing data and experience.

- Determine the appropriate solution and implement it.

- Monitor the machine after troubleshooting to ensure the issue is resolved.

- Document the problem and solution for future reference.

5. What are the safety precautions to be observed when operating a broke beater machine?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures before performing any maintenance or repairs.

- Maintain a safe work area free from hazards.

- Be aware of moving parts and keep a safe distance.

- Report any unsafe conditions or incidents immediately.

6. How do you optimize the efficiency of a broke beater machine?

- Regularly calibrate the machine to maintain optimal performance.

- Use high-quality raw materials to minimize waste.

- Monitor and adjust process parameters to maximize production output.

- Perform preventive maintenance to minimize downtime.

- Train operators on best practices to improve efficiency.

7. What is the difference between a broke beater and a pulper?

- A broke beater is used to process waste paper materials into a pulp.

- A pulper is used to separate fibers from other materials.

- The broke beater typically has a rotating drum with beater bars, while the pulper uses a rotating impeller with blades.

- The broke beater produces a finer pulp than the pulper.

- The broke beater is typically used in the papermaking process, while the pulper is used in a variety of industries.

8. How do you determine the consistency of the pulp produced by the broke beater machine?

- Use a consistency meter to measure the percentage of solids in the pulp.

- Adjust the machine settings to achieve the desired consistency.

- Monitor the consistency regularly to ensure it meets specifications.

- Document the consistency measurements for quality control purposes.

9. What are the environmental considerations associated with operating a broke beater machine?

- Wastewater treatment to remove pollutants from the process water.

- Energy efficiency to reduce carbon emissions.

- Recycling of waste materials to minimize landfill waste.

- Compliance with environmental regulations.

- Continual improvement of environmental practices.

10. How do you stay updated with the latest advancements in broke beater machine technology?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Seek training and certification opportunities.

- Collaborate with equipment manufacturers to learn about new technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Broke Beater Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Broke Beater Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Broke Beater Machine Operators are responsible for overseeing and operating broke beater machines in paper mills. Their primary duties involve:

1. Machine Operation and Maintenance

Operate broke beater machines to break down rejected paper and cardboard into a pulp suitable for reprocessing.

- Monitor and adjust machine settings to ensure efficient operation and pulp quality.

- Perform regular maintenance and repairs on machines to keep them in optimal condition.

2. Pulp Quality Control

Monitor pulp quality using testing equipment and adjust machine parameters to meet specifications.

- Conduct regular checks on pulp consistency, freeness, and fiber length.

- Make necessary adjustments to machine settings or chemical additions to maintain desired pulp quality.

3. Production Monitoring and Optimization

Monitor production output and identify areas for improvement in efficiency and yield.

- Analyze production data to identify bottlenecks and potential improvements.

- Implement process modifications or adjustments to increase production or reduce waste.

4. Safety and Compliance

Adhere to all safety regulations and procedures while operating machines and handling chemicals.

- Wear appropriate personal protective equipment (PPE) and follow established safety protocols.

- Maintain a clean and organized work area to minimize hazards.

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your Broke Beater Machine Operator interview:

1. Research the Company and Role

Familiarize yourself with the company’s website, industry reputation, and specific requirements of the Broke Beater Machine Operator position.

- Tailor your answers to the company’s needs and demonstrate your understanding of the industry.

- Highlight the skills and experiences that align with the job responsibilities outlined in the description.

2. Practice Your Responses

Go through common interview questions and prepare thoughtful answers that showcase your qualifications and enthusiasm for the role.

- Focus on providing specific examples from your previous work experience that demonstrate your abilities.

- Quantify your achievements using numbers and metrics whenever possible.

3. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress appropriately and arrive for your interview punctually.

- Choose clean and pressed business attire that reflects the professional nature of the position.

- Plan your route and transportation in advance to avoid any delays.

4. Be Confident and Enthusiastic

Convey your confidence in your abilities and enthusiasm for the opportunity. Maintain good body language and make eye contact with the interviewer.

- Use positive and upbeat language, and avoid negative or self-deprecating remarks.

- Show genuine interest in the company and the role, and ask thoughtful questions to demonstrate your engagement.

5. Follow Up and Thank the Interviewer

After the interview, send a follow-up email to thank the interviewer for their time and consideration.

- Reiterate your interest in the position and highlight any additional qualifications or experiences you may have forgotten to mention.

- Express your appreciation for the opportunity to interview and reiterate your confidence in your ability to excel in the role.

Next Step:

Now that you’re armed with the knowledge of Broke Beater Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Broke Beater Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini