Are you gearing up for a career in Broommaking Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Broommaking Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

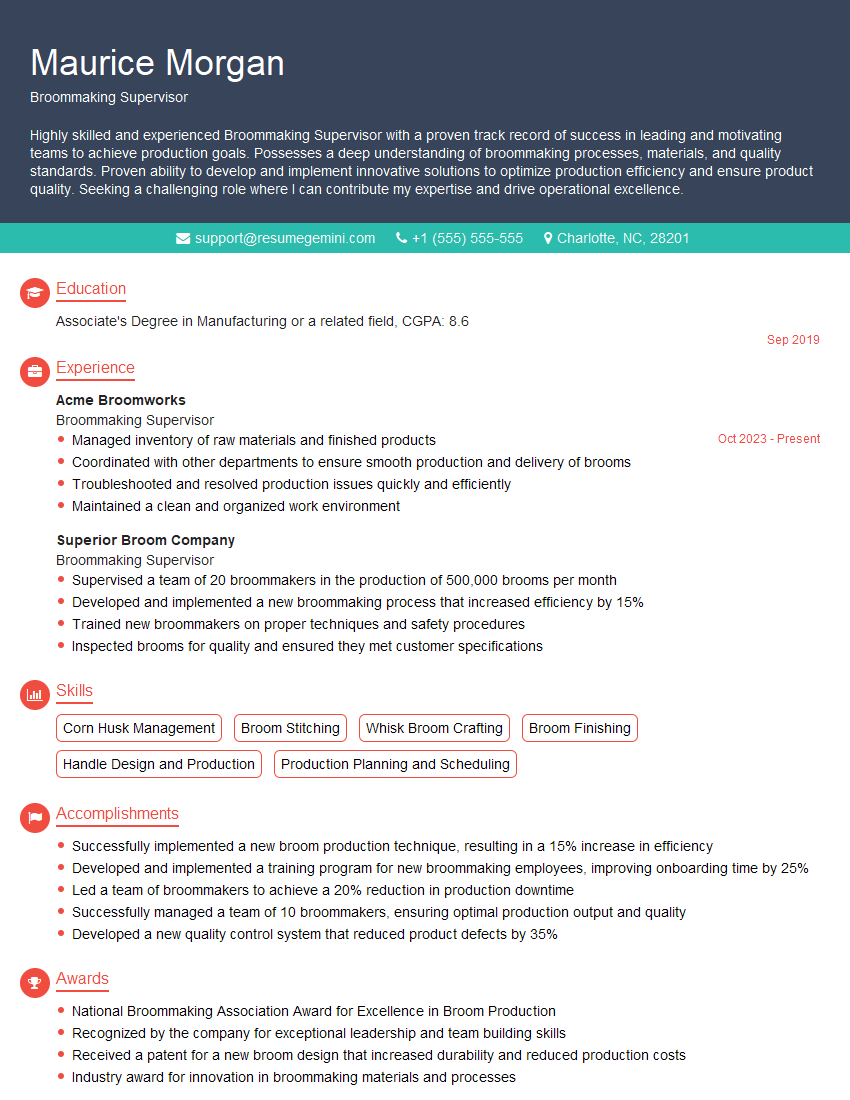

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Broommaking Supervisor

1. What are the key factors to consider when selecting raw materials for broom making?

The key factors to consider when selecting raw materials for broom making include:

- Fiber strength and durability: The fibers should be strong and durable enough to withstand the wear and tear of sweeping.

- Fiber length and flexibility: The fibers should be of the correct length and flexibility to create a broom that is effective and easy to use.

- Cost: The cost of the raw materials should be taken into consideration when selecting materials.

- Availability: The materials should be readily available and accessible.

- Environmental impact: The environmental impact of the raw materials should be considered, such as their sustainability and biodegradability.

2. How do you ensure the quality of brooms produced in your facility?

Quality Control Measures:

- Raw material inspection: Inspecting raw materials for quality and consistency.

- Process monitoring: Monitoring the broom making process to ensure it adheres to standards.

- Finished product testing: Testing finished brooms to ensure they meet performance specifications.

Quality Standards:

- Industry standards: Compliance with industry standards for broom quality.

- Customer specifications: Meeting customer-specific quality requirements.

- Continuous improvement: Regularly reviewing and improving quality control processes.

3. Describe the process of setting up and operating a broom making machine.

- Machine preparation: Ensuring the machine is clean, well-maintained, and correctly calibrated.

- Raw material loading: Loading the machine with the appropriate raw materials, such as fibers and handles.

- Machine operation: Operating the machine to create brooms according to specified parameters, such as broom size, shape, and density.

- Quality control: Monitoring the machine’s operation and checking the quality of the produced brooms.

- Maintenance and troubleshooting: Performing routine maintenance and troubleshooting any issues that may arise during operation.

4. What are the common problems that can occur during broom making and how do you troubleshoot them?

- Uneven bristles: Adjusting the machine settings or inspecting the raw materials for consistency.

- Loose bristles: Checking the tightness of the binding or using a different type of adhesive.

- Bent handles: Inspecting the handling process or using higher quality handles.

- Broken bristles: Inspecting the raw materials or adjusting the machine’s settings.

- Inefficient sweeping: Analyzing the broom design or using different raw materials.

5. How do you manage and motivate a team of broom makers?

Management Strategies:

- Clear communication: Establishing clear expectations, goals, and procedures.

- Regular feedback: Providing timely feedback on performance and areas for improvement.

- Recognition and rewards: Acknowledging and rewarding employee contributions and achievements.

- Training and development: Investing in employee training and development to enhance skills.

Motivation Techniques:

- Empowerment: Giving employees a sense of ownership and responsibility.

- Positive work environment: Creating a supportive and positive work environment.

- Team building: Encouraging teamwork and collaboration.

- Incentives and bonuses: Offering incentives and bonuses to motivate performance.

6. What is your approach to waste reduction and sustainability in broom making?

- Raw material optimization: Efficiently utilizing raw materials to minimize waste.

- Recycling and reuse: Implementing recycling programs for waste materials and reusing materials whenever possible.

- Energy efficiency: Optimizing energy consumption in the production process.

- Sustainable materials: Exploring the use of sustainable and biodegradable materials.

- Collaboration with suppliers: Working with suppliers to promote sustainable practices throughout the supply chain.

7. How do you stay up-to-date with the latest trends and technologies in broom making?

- Industry events and conferences: Attending industry events to learn about new products, technologies, and best practices.

- Trade publications and online resources: Reading trade publications and accessing online resources to stay informed about industry trends.

- Research and development: Conducting research and development to explore new materials and techniques.

- Collaboration with experts: Consulting with experts in the field to gain insights and knowledge.

8. Describe your experience in training and developing new broom makers.

- Orientation and onboarding: Providing new hires with a comprehensive overview of the broom making process and company policies.

- On-the-job training: Supervising and guiding new hires as they learn the hands-on aspects of broom making.

- Mentoring and coaching: Assigning experienced broom makers to mentor and support new hires.

- Performance evaluation and feedback: Regularly assessing progress and providing constructive feedback to facilitate improvement.

- Continued education and development: Encouraging new hires to pursue further training and development opportunities to enhance their skills.

9. What are your strengths and weaknesses as a Broommaking Supervisor?

Strengths:

- Technical expertise: Possessing a deep understanding of broom making techniques and processes.

- Team leadership: Proven ability to lead and motivate a team of broom makers effectively.

- Quality assurance: Committed to maintaining high quality standards in broom production.

- Problem-solving: Skilled in identifying and resolving issues that arise during production.

- Communication: Excellent communication skills to convey instructions, provide feedback, and resolve conflicts.

Weaknesses:

- Limited experience in automation: Acknowledging a need to gain more experience in automating broom making processes.

- Delegation: Continuously working to improve delegation skills to empower team members.

- Time management: Occasionally facing challenges in managing time effectively during peak production periods.

10. Why are you interested in this Broommaking Supervisor position?

- Passion for broom making: Expressing a genuine interest in the craft of broom making and its importance in various industries.

- Growth opportunity: Viewing the position as an opportunity for professional growth and career advancement.

- Contribution to the company: Demonstrating enthusiasm for contributing to the company’s success and reputation for producing high-quality brooms.

- Teamwork environment: Expressing excitement about working with a team of skilled broom makers.

- Alignment with values: Highlighting how the company’s values align with personal values, such as quality, sustainability, and customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Broommaking Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Broommaking Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Broommaking Supervisor is responsible for overseeing the production of brooms, ensuring that they meet quality standards. They are responsible for managing a team of broommakers, as well as for the day-to-day operations of the broommaking facility. The Broommaking Supervisor reports directly to the Plant Manager.

1. Production

The Broommaking Supervisor is responsible for ensuring that the broommaking facility produces brooms that meet quality standards. This includes setting production goals, developing and implementing quality control procedures, and inspecting brooms before they are shipped to customers.

- Set production goals and targets

- Develop and implement quality control procedures

- Inspect brooms before they are shipped to customers

2. Management

The Broommaking Supervisor is responsible for managing a team of broommakers. This includes hiring, training, and evaluating broommakers, as well as providing them with support and guidance.

- Hire, train, and evaluate broommakers

- Provide broommakers with support and guidance

- Resolve any issues that arise between broommakers

3. Operations

The Broommaking Supervisor is responsible for the day-to-day operations of the broommaking facility. This includes ensuring that the facility is clean and safe, and that all equipment is in good working order.

- Ensure that the broommaking facility is clean and safe

- Ensure that all equipment is in good working order

- Order supplies and materials

4. Reporting

The Broommaking Supervisor is responsible for reporting to the Plant Manager on the performance of the broommaking facility. This includes providing regular updates on production, quality, and costs.

- Provide regular updates on production to the Plant Manager

- Provide regular updates on quality to the Plant Manager

- Provide regular updates on costs to the Plant Manager

Interview Tips

Here are some tips to help you ace your interview for a Broommaking Supervisor position:

1. Research the Company

Before your interview, take the time to research the company. This will help you understand the company’s culture, values, and goals. You should also learn about the company’s products and services, as well as its competitors. This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance. This will help you feel more confident and prepared during your interview.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in the broommaking industry. Be prepared to talk about your skills and experience in broommaking, as well as your experience in managing a team. You should also be prepared to talk about your quality control experience.

4. Be Enthusiastic and Positive

The interviewer will be looking for someone who is enthusiastic about the broommaking industry and who is passionate about their work. Be sure to show the interviewer that you are excited about the opportunity to work for the company. You should also be positive and upbeat during your interview.

5. Follow Up After the Interview

After your interview, be sure to follow up with the interviewer. Thank them for their time and let them know that you are still interested in the position. You can also use this opportunity to reiterate your qualifications and to answer any questions that the interviewer may have forgotten to ask.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Broommaking Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.