Are you gearing up for an interview for a Brush Head Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Brush Head Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

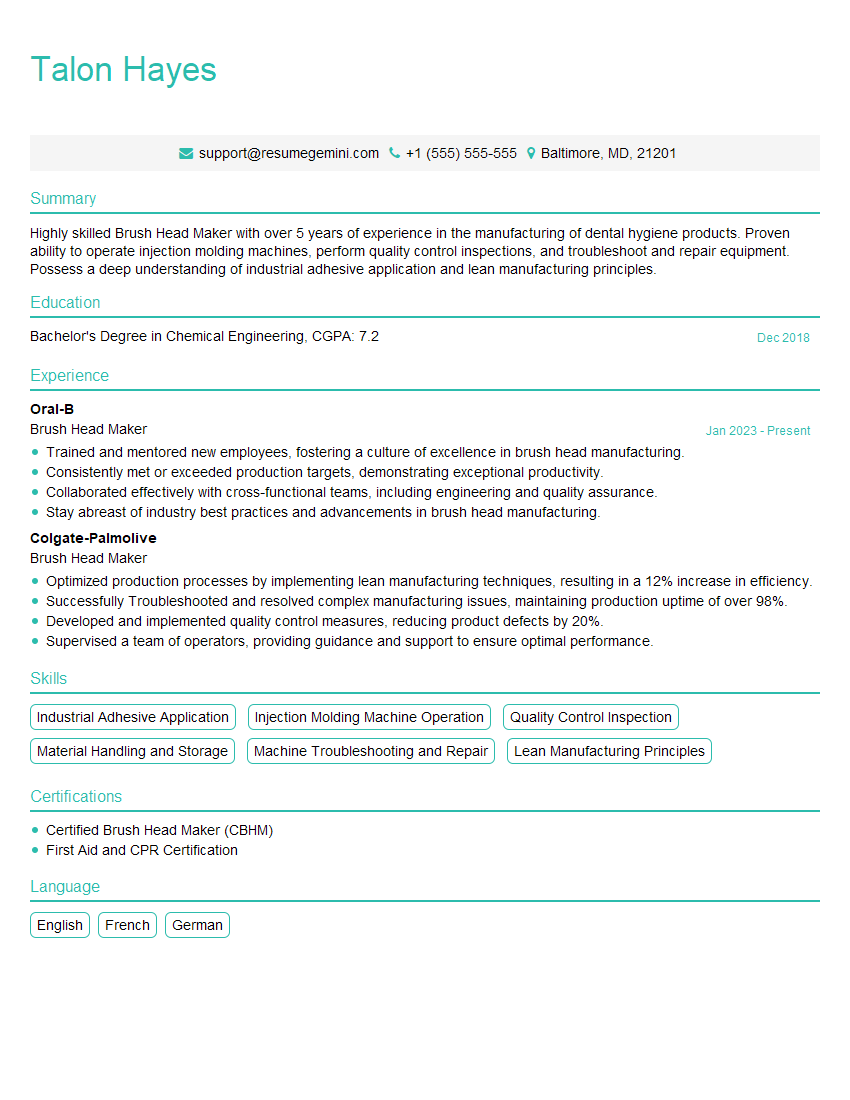

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brush Head Maker

1. What are the different types of materials used to make brush heads?

- Natural materials, such as animal hair, vegetable fibers, and minerals

- Synthetic materials, such as nylon, polyester, and polypropylene

2. What are the advantages and disadvantages of using natural vs. synthetic materials for brush heads?

Advantages of natural materials

- Biodegradable

- Durable

- Gentle on surfaces

Advantages of synthetic materials

- Less expensive

- More durable

- More resistant to chemicals and heat

3. What factors should be considered when choosing the type of material for a brush head?

- The intended use of the brush

- The type of surface to be cleaned

- The desired level of stiffness or softness

- The budget

4. What are the different types of brush head shapes and designs?

- Round

- Oval

- Square

- Rectangular

- Angled

5. What are the pros and cons of different brush head shapes and designs?

- Round brushes are good for all-purpose cleaning.

- Oval brushes are good for cleaning curved surfaces.

- Square brushes are good for cleaning corners and crevices.

- Rectangular brushes are good for cleaning large, flat surfaces.

- Angled brushes are good for cleaning hard-to-reach areas.

6. What are the different types of bristle configurations and densities?

- Single bristles

- Double bristles

- Triple bristles

- Flagged bristles (splayed at the ends)

- Twisted bristles

7. What factors should be considered when choosing the bristle configuration and density?

- The type of surface to be cleaned

- The desired level of cleaning power

- The durability of the bristles

- The cost of the brush

8. What are the different methods used to attach bristles to brush heads?

- Stapling

- Gluing

- Injection molding

- Ultrasonic welding

9. What are the pros and cons of different bristle attachment methods?

- Stapling is a simple and inexpensive method, but it can weaken the bristles.

- Gluing is a strong and durable method, but it can be messy and time-consuming.

- Injection molding is a precise and efficient method, but it requires specialized equipment.

- Ultrasonic welding is a fast and clean method, but it can be expensive.

10. What are the quality control standards for brush heads?

- The bristles should be evenly spaced and securely attached.

- The brush head should be free of defects, such as cracks or chips.

- The brush head should meet the specified dimensions and tolerances.

- The brush head should be able to withstand the intended use.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brush Head Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brush Head Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Brush Head Maker is responsible for manufacturing and assembling brush heads used for toothbrushes, makeup brushes, and various other applications. The key job responsibilities include:

1. Production and Assembly

Operate automated or semi-automated machines to produce brush heads.

- Set up and adjust machines according to specifications.

- Monitor production processes to ensure quality and efficiency.

2. Materials Handling

Handle and transport raw materials and finished products within the production area.

- Inspect materials for defects before use.

- Maintain inventory of materials and keep work area organized.

3. Quality Assurance and Inspection

Inspect brush heads for defects and ensure compliance with quality standards.

- Perform visual inspections and use measuring instruments to assess product quality.

- Record and document inspection results for traceability purposes.

4. Equipment Maintenance and Troubleshooting

Maintain and troubleshoot production equipment to ensure optimal performance.

- Perform routine cleaning and lubrication of machines.

- Identify and resolve equipment malfunctions, minimizing downtime.

Interview Tips

To prepare for an interview for a Brush Head Maker position, it is important to:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and manufacturing processes.

- Research the brush making industry and understand the latest trends and technologies.

- Example: Highlight your knowledge of the company’s focus on sustainable manufacturing practices to show alignment with their values.

2. Highlight Relevant Skills and Experience

Emphasize your experience in brush production, materials handling, and quality control.

- Provide specific examples of your skills in operating and maintaining production equipment.

- Example: Showcase your ability to identify and troubleshoot equipment issues, reducing downtime and improving production efficiency.

3. Demonstrate Attention to Detail and Quality

Stress your commitment to producing high-quality brush heads.

- Explain your approach to ensuring product quality through rigorous inspection procedures.

- Example: Describe your experience in implementing quality control measures that resulted in reduced defect rates.

4. Show Interest and Enthusiasm for the Role

Express your passion for brush making and explain why you are interested in the position.

- Explain how your skills and experience align with the company’s needs and the specific job responsibilities.

- Example: Emphasize your eagerness to contribute to the production of high-quality brush heads that meet customer expectations.

Next Step:

Now that you’re armed with the knowledge of Brush Head Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Brush Head Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini