Are you gearing up for a career in Brusher Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Brusher Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

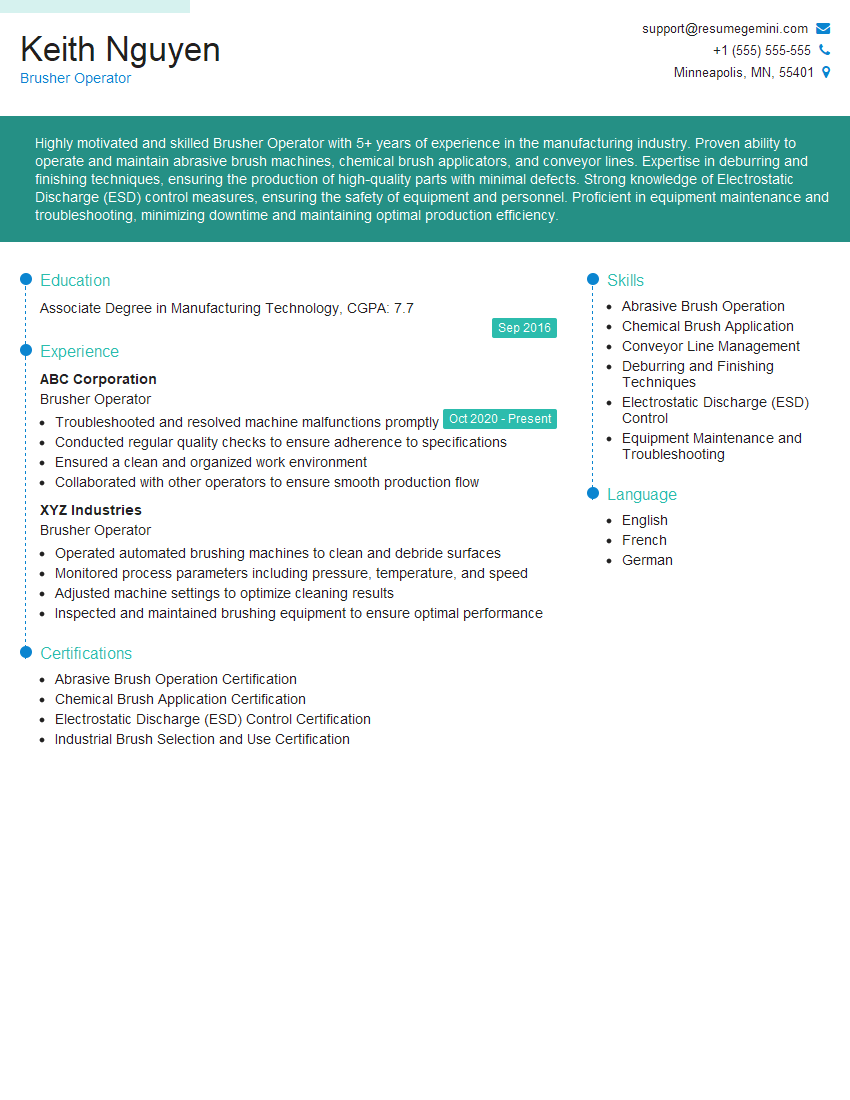

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brusher Operator

1. What are the different types of brushes used in industrial brushing operations?

- Natural fiber brushes: These brushes are made from natural materials such as horsehair, tampico, and sisal. They are commonly used for cleaning and finishing applications.

- Synthetic fiber brushes: These brushes are made from man-made materials such as nylon, polyester, and polypropylene. They are more durable and resistant to chemicals than natural fiber brushes, making them suitable for heavy-duty applications.

- Abrasive brushes: These brushes have abrasive particles embedded in the bristles. They are used for removing burrs, rust, and other surface contaminants.

- Wire brushes: These brushes have metal bristles. They are used for heavy-duty cleaning and deburring applications.

2. Explain the process of selecting the right brush for a specific application.

- Determine the purpose of the brushing operation (e.g., cleaning, finishing, deburring).

- Identify the material being brushed (e.g., metal, plastic, wood).

- Consider the surface condition of the material (e.g., smooth, rough, delicate).

- Select a brush with the appropriate type of bristles (e.g., natural fiber, synthetic fiber, abrasive, wire).

- Choose a brush with the appropriate stiffness and density.

- Ensure the brush is compatible with the equipment being used.

3. What are the safety precautions that should be followed when operating a brushing machine?

- Wear appropriate personal protective equipment (e.g., gloves, safety glasses, hearing protection).

- Inspect the machine before each use and ensure it is in good working condition.

- Keep hands, hair, and clothing away from moving parts.

- Use the machine in a well-ventilated area to avoid inhaling dust or fumes.

- Follow the manufacturer’s instructions for safe operation.

4. How do you maintain a brushing machine to ensure optimal performance?

- Clean the machine regularly to remove dust, debris, and contaminants.

- Inspect the brushes for wear and tear and replace them as needed.

- Lubricate the machine according to the manufacturer’s instructions.

- Store the machine in a clean and dry environment.

- Follow the manufacturer’s recommended maintenance schedule.

5. What are the common troubleshooting steps for a brushing machine that is not functioning properly?

- Check the power supply and ensure the machine is receiving power.

- Inspect the brushes for wear and tear and replace them if necessary.

- Clean the machine to remove any debris or contaminants that may be causing problems.

- Check the belt or chain drive for damage or wear and replace if necessary.

- Contact the manufacturer for further assistance if the problem cannot be resolved.

6. What are the different types of industrial brushing machines?

- Manual brushing machines: These machines are operated by hand and are typically used for small-scale brushing operations.

- Power brushing machines: These machines are powered by an electric motor or air compressor and are used for more demanding brushing applications.

- Automated brushing machines: These machines are programmed to perform specific brushing tasks and are used for high-volume production.

7. What are the benefits of using a brushing machine for industrial applications?

- Improved surface finish: Brushing can remove burrs, rust, and other surface contaminants, resulting in a smoother and more aesthetically pleasing finish.

- Increased productivity: Brushing machines can automate repetitive brushing tasks, freeing up workers for other tasks.

- Improved product quality: Brushing can help to ensure that products meet the desired quality standards.

- Reduced labor costs: Brushing machines can help to reduce labor costs by automating tasks that would otherwise have to be performed manually.

8. What are the challenges of working as a Brusher Operator?

- Exposure to dust and fumes: Brushing operations can generate dust and fumes, which can be harmful to health if not properly controlled.

- Repetitive motions: Brusher Operators often perform repetitive motions, which can lead to muscle strain and fatigue.

- Working in confined spaces: Brusher Operators may have to work in confined spaces, which can be uncomfortable and dangerous.

9. What are the qualities of a successful Brusher Operator?

- Attention to detail: Brusher Operators must be able to pay close attention to detail to ensure that the desired finish is achieved.

- Physical stamina: Brusher Operators must be able to stand for long periods of time and perform repetitive motions.

- Good communication skills: Brusher Operators must be able to communicate effectively with supervisors and other employees.

- Ability to work independently: Brusher Operators often work independently and must be able to follow instructions and complete tasks without supervision.

10. What are your career goals as a Brusher Operator?

- I am eager to learn all aspects of brushing operations and become a highly skilled Brusher Operator.

- I am interested in exploring different brushing applications and industries.

- I am committed to continuous improvement and I strive to exceed expectations in all that I do.

- I am confident that I can make a valuable contribution to your company and I am excited about the opportunity to grow my career as a Brusher Operator.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brusher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brusher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brusher Operators are responsible for operating and maintaining brush machines used in various industries, such as manufacturing, automotive, and construction. They ensure that the machines are functioning properly and efficiently to achieve desired surface finishes and meet quality standards.

1. Machine Operation and Maintenance

Set up and operate brush machines according to specifications, ensuring proper brush alignment, speed, and pressure.

- Monitor machine performance and make necessary adjustments to optimize efficiency.

- Maintain and troubleshoot the machine, performing routine cleaning, lubrication, and repairs as needed.

2. Surface Preparation and Finishing

Prepare surfaces for brushing by cleaning, sanding, or applying primers as required.

- Select appropriate brushes and abrasive materials based on the desired surface finish.

- Brush surfaces to achieve specific textures, remove burrs, or polish materials.

3. Quality Control and Inspection

Inspect brushed surfaces to ensure they meet specifications and quality standards.

- Use measuring instruments and gauges to verify dimensions, surface roughness, and other relevant parameters.

- Identify and correct any defects or imperfections found during inspection.

4. Safety and Environment

Follow established safety procedures and wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area to ensure safety and prevent contamination.

- Dispose of waste materials and hazardous substances in accordance with environmental regulations.

Interview Tips

Preparing for a Brusher Operator interview requires a combination of technical knowledge and a strong understanding of the industry. Here are some tips to help you ace the interview:

1. Brush Machine Knowledge

Research different types of brush machines, their applications, and operating principles.

- Familiarize yourself with brush materials, abrasives, and their effects on different surfaces.

- Be prepared to discuss your experience in setting up, operating, and maintaining brush machines.

2. Surface Preparation and Finishing Techniques

Understand surface preparation methods and their impact on the final finish.

- Practice explaining your knowledge of different brushing techniques, including dry brushing, wet brushing, and abrasive brushing.

- Prepare examples of your work, showcasing your skills in achieving specific surface finishes.

3. Quality Control and Inspection Procedures

Explain your understanding of quality control standards and inspection processes.

- Describe your experience using measuring instruments and gauges to verify surface dimensions and roughness.

- Be prepared to discuss how you identify and correct any defects or imperfections.

4. Safety and Environmental Awareness

Emphasize your commitment to workplace safety and environmental regulations.

- Explain your understanding of proper PPE usage and safe work practices.

- Discuss your experience in waste disposal and hazardous substance handling procedures.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Brusher Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.