Are you gearing up for a career in Buckle Gluer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Buckle Gluer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

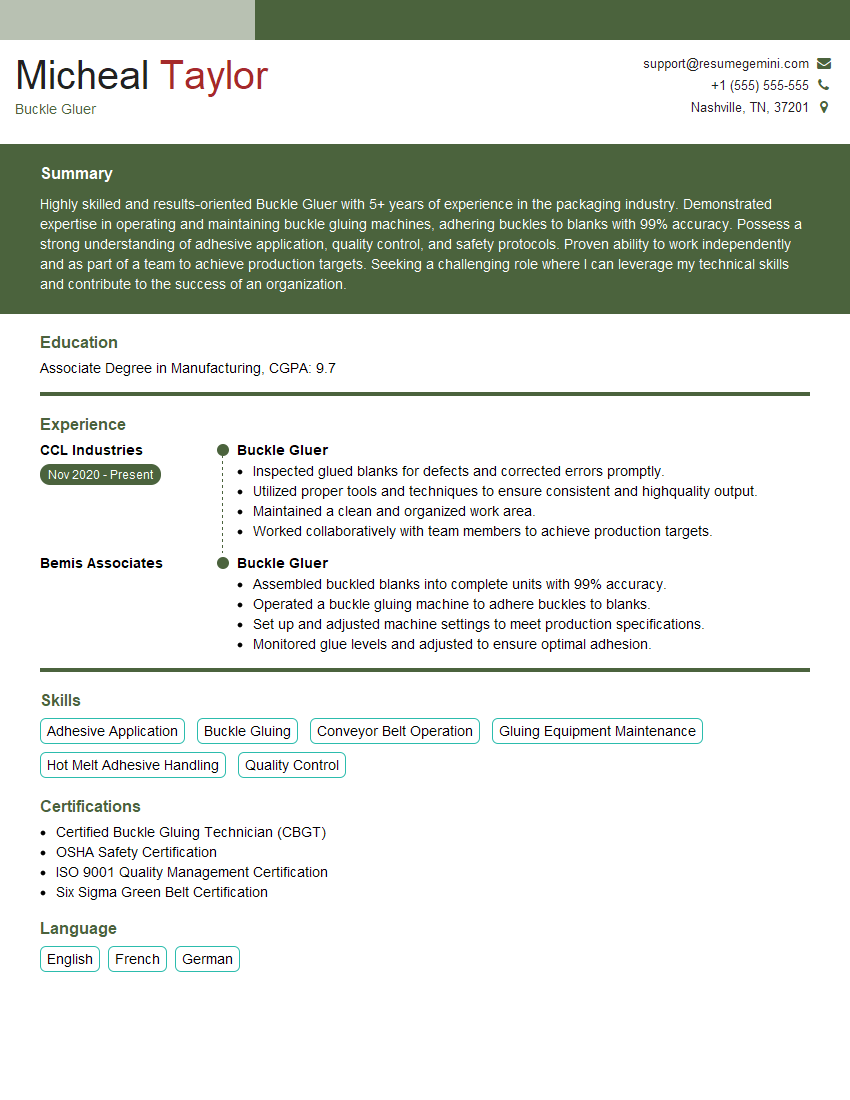

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Buckle Gluer

1. Describe the process of buckle gluing in detail.

Buckle gluing is a process of applying a layer of glue to the inside of a buckle to hold it securely in place. It is a critical step in the production of many products, including shoes, belts, and handbags.

- The first step is to prepare the buckle by cleaning it and removing any dirt or debris.

- Next, a thin layer of glue is applied to the inside of the buckle using a brush or glue applicator.

- The buckle is then placed on the product and pressed into place.

- The glue is allowed to dry for a period of time, which can vary depending on the type of glue used.

- Once the glue has dried, the buckle is securely attached to the product.

2. What are the different types of buckle gluing machines, and what are their advantages and disadvantages?

There are several different types of buckle gluing machines, each with its own advantages and disadvantages.

Manual buckle gluing machines

- Advantages: Manual buckle gluing machines are less expensive than automatic machines and can be used for a wider variety of buckles.

- Disadvantages: Manual buckle gluing machines are slower and require more labor than automatic machines.

Semi-automatic buckle gluing machines

- Advantages: Semi-automatic buckle gluing machines are faster than manual machines and require less labor.

- Disadvantages: Semi-automatic buckle gluing machines are more expensive than manual machines and can only be used for a limited variety of buckles.

Fully automatic buckle gluing machines

- Advantages: Fully automatic buckle gluing machines are the fastest and most efficient type of buckle gluing machine.

- Disadvantages: Fully automatic buckle gluing machines are the most expensive type of buckle gluing machine and can only be used for a limited variety of buckles.

3. What are the common problems that can occur during buckle gluing, and how can they be solved?

There are several common problems that can occur during buckle gluing, including:

- The glue does not adhere to the buckle.

- The buckle is not positioned correctly on the product.

- The glue dries too quickly.

- The glue dries too slowly.

These problems can be solved by following the manufacturer’s instructions carefully and by using the correct type of glue for the job.

4. What are the safety precautions that should be taken when using a buckle gluing machine?

There are several safety precautions that should be taken when using a buckle gluing machine, including:

- Wear gloves and safety glasses.

- Keep the machine clean and free of debris.

- Do not operate the machine while under the influence of alcohol or drugs.

- Follow the manufacturer’s instructions carefully.

5. What maintenance tasks are required for a buckle gluing machine?

There are several maintenance tasks that are required for a buckle gluing machine, including:

- Cleaning the machine regularly.

- Oiling the machine regularly.

- Inspecting the machine for damage.

- Calibrating the machine regularly.

6. What is the difference between hot melt glue and cold glue?

Hot melt glue is a type of glue that is melted before it is applied. It is typically used for bonding materials that are not heat-sensitive. Cold glue is a type of glue that is applied at room temperature. It is typically used for bonding materials that are heat-sensitive.

7. What are the different types of adhesives that can be used for buckle gluing?

There are several different types of adhesives that can be used for buckle gluing, including:

- Hot melt adhesives

- Cold glues

- Pressure-sensitive adhesives

- Anaerobic adhesives

8. What are the factors that affect the strength of a glued joint?

The strength of a glued joint is affected by several factors, including:

- The type of adhesive used

- The surface area of the joint

- The thickness of the joint

- The pressure applied to the joint

- The temperature of the joint

9. What are the different types of buckles that can be glued?

There are several different types of buckles that can be glued, including:

- Metal buckles

- Plastic buckles

- Fabric buckles

- Leather buckles

10. What are the different applications for buckle gluing?

Buckle gluing is used in a variety of applications, including:

- Shoes

- Belts

- Handbags

- Other accessories

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Buckle Gluer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Buckle Gluer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Buckle Gluers are responsible for operating and maintaining buckle gluing machines in a manufacturing environment. Their primary tasks involve applying glue to buckles and attaching them to various materials, ensuring precise alignment and bonding for optimal product quality.

1. Machine Operation and Maintenance

• Operate buckle gluing machines to apply adhesive to buckles accurately.

• Adjust machine settings and parameters to optimize glue application and bonding.

• Monitor machine performance, identify malfunctions, and perform routine maintenance.

• Ensure proper ventilation and safety protocols are followed during machine operation.

2. Buckle Alignment and Attachment

• Align buckles precisely on designated materials before gluing.

• Apply glue to buckles using manual or automated techniques.

• Attach buckles firmly to materials, ensuring proper adhesion and alignment.

• Implement quality control checks to verify buckle attachment and bonding strength.

3. Material Handling and Preparation

• Load materials into the gluing machine correctly to facilitate efficient operation.

• Inspect materials for defects or irregularities that may impact gluing quality.

• Prepare materials by cleaning, sanding, or applying primers as required.

• Ensure that materials meet specifications and are compatible with the gluing process.

4. Glue Management and Control

• Monitor glue levels and replenish as needed to maintain optimal gluing performance.

• Inspect glue for consistency, viscosity, and expiration dates to ensure quality.

• Adjust glue application settings to optimize bond strength and prevent excess glue waste.

• Maintain a clean and organized gluing area to minimize contamination and ensure safety.

Interview Tips

To ace an interview for a Buckle Gluer position, it is important to prepare thoroughly and demonstrate your knowledge and skills related to the role. Here are some interview preparation tips:

1. Research the Company and Industry

• Familiarize yourself with the company’s mission, values, and products/services.

• Research the buckle gluing industry, including market trends and technological advancements.

• Understand the specific industry in which the company operates, such as automotive, fashion, or packaging.

2. Practice Interview Questions

• Anticipate common interview questions related to your experience, skills, and motivation.

• Prepare concise and well-structured answers that demonstrate your qualifications.

• Use the job description to identify key responsibilities and tailor your answers accordingly.

3. Highlight Relevant Skills and Experience

• Emphasize your experience operating and maintaining buckle gluing machines.

• Showcase your ability to achieve precise buckle alignment and bonding.

• Describe your knowledge of different types of glues and their applications.

4. Prepare Questions for the Interviewers

• Show your interest and engagement by preparing insightful questions related to the position.

• Ask about the company’s expectations, advancement opportunities, and safety protocols.

• Inquire about the specific gluing techniques and challenges involved.

5. Dress Professionally and Maintain a Positive Attitude

• Dress appropriately for the interview to show respect and make a good impression.

• Maintain a positive and confident demeanor throughout the interview.

• Be enthusiastic about the position and express your eagerness to contribute to the team.

Next Step:

Now that you’re armed with the knowledge of Buckle Gluer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Buckle Gluer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini