Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Buckle Strap Drum Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Buckle Strap Drum Operator so you can tailor your answers to impress potential employers.

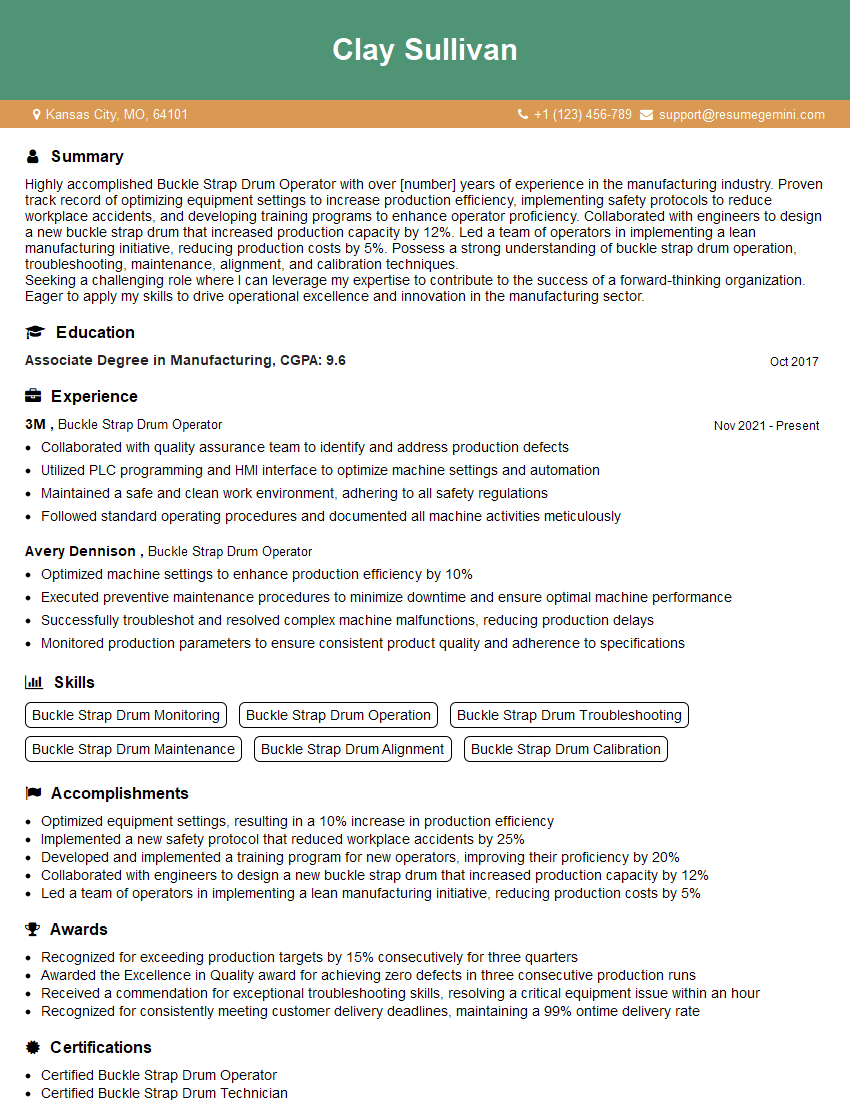

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Buckle Strap Drum Operator

1. How do you secure the buckle strap to the drum?

There are a few different ways to secure a buckle strap to a drum. One common method is to use a clove hitch. To do this, pass the end of the strap through the buckle and then around the outside of the drum. Bring the end of the strap back through the buckle and tighten it. Another method is to use a bowline knot. To do this, pass the end of the strap through the buckle and then around the outside of the drum. Bring the end of the strap back through the buckle and then through the loop that was created. Tighten the knot.

2. How do you adjust the tension of the buckle strap?

Adjusting Buckle Strap Tension

- Loosen buckle strap by pulling on loose end of the strap.

- Tighten buckle strap by pulling on the fixed end of the strap.

Checking Buckle Strap Tension

- Check the tension of the strap by pressing on the top of the drum.

- The strap should be tight enough to prevent the drum from slipping, but not so tight that it damages the drum.

3. How do you inspect a buckle strap for damage?

Regularly inspect your buckle strap to ensure it is in good condition and will keep your drum secure. Inspect the strap for any signs of wear or damage, such as:

- Cracks or tears in the strap

- Broken or damaged buckles

- Frayed or worn edges

- Rust or corrosion

4. How often should you replace a buckle strap?

The frequency with which you should replace a buckle strap will depend on several factors, including the frequency of use, the type of drum, and the environment in which the drum is used. As a general rule, you should replace a buckle strap every 12-18 months. However, if you notice any signs of damage, you should replace the strap immediately.

5. What are the different types of buckle straps available?

There are a variety of different buckle straps available, each with its own unique advantages and disadvantages. Some of the most common types of buckle straps include:

- Nylon straps: Nylon straps are lightweight and durable, making them a good choice for general-purpose use.

- Polyester straps: Polyester straps are even stronger than nylon straps, making them a good choice for heavy-duty applications.

- Leather straps: Leather straps are strong and durable, and they also add a touch of style to your drum.

- Webbing straps: Webbing straps are made from a variety of materials, including nylon, polyester, and polypropylene. They are strong and durable, and they can be easily adjusted to the desired length.

6. How do you choose the right buckle strap for your drum?

When selecting a buckle strap for your drum, there are several factors to consider, including:

- The size of your drum

- The weight of your drum

- The frequency with which you use your drum

- The environment in which you use your drum

7. What are some tips for using a buckle strap safely?

Here are some tips for using a buckle strap safely:

- Always inspect the strap before each use.

- Make sure the strap is the correct size for your drum.

- Tighten the strap until it is snug, but not too tight.

- Never use a strap that is damaged or worn.

- Replace the strap every 12-18 months, or more often if necessary.

8. What are some common problems associated with buckle straps?

Some common problems associated with buckle straps include:

- The strap can become loose over time, which can cause the drum to slip.

- The strap can break if it is overloaded or used improperly.

- The buckle can become damaged or corroded, which can make it difficult to use.

9. How do you troubleshoot problems with buckle straps?

If you are experiencing problems with a buckle strap, there are a few things you can do to troubleshoot the problem:

- Inspect the strap for any signs of damage or wear.

- Check the tension of the strap. It may need to be tightened or loosened.

- Inspect the buckle for any signs of damage or corrosion.

- If the problem cannot be resolved, you may need to replace the strap.

10. What is the most important thing to remember when using a buckle strap?

The most important thing to remember when using a buckle strap is to always use it safely. This means inspecting the strap before each use, making sure it is the correct size for your drum, tightening it until it is snug but not too tight, and never using a strap that is damaged or worn.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Buckle Strap Drum Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Buckle Strap Drum Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Buckle Strap Drum Operator, you will be responsible for managing the operation of a buckle strap drum machine, ensuring the production of high-quality and consistent strap drums.

1. Machine Operation

You will be responsible for initializing and maintaining the operation of the buckle strap drum machine, monitoring its key performance metrics to ensure optimal production.

- Set up and calibrate the machine according to established specifications

- Monitor the machine during operation and troubleshoot any issues or malfunctions

2. Quality Control

You will be responsible for conducting regular quality checks on the produced strap drums to guarantee they meet the required standards, ensuring customer satisfaction.

- Inspect the strap drums for defects or inconsistencies, including dimensional accuracy and surface quality

- Document and report any quality issues to supervisors or quality control personnel

3. Process Optimization

You will be expected to identify and implement process improvements to enhance the efficiency and productivity of the buckle strap drum production line, reducing waste and increasing output.

- Monitor production rates and identify bottlenecks or areas for improvement

- Collaborate with engineers and other team members to develop and implement solutions to optimize processes

4. Safety and Compliance

You will be responsible for adhering to established safety protocols and industry regulations to ensure a safe working environment and minimize potential hazards.

- Follow all safety procedures and wear appropriate personal protective equipment

- Report any safety concerns or hazards to supervisors immediately

Interview Tips

Preparing for your Buckle Strap Drum Operator interview is crucial. Here are some tips to enhance your chances of success:

1. Research the Company and Industry

Become familiar with the company’s background, its products or services, and its position within the industry. Understanding the company’s culture and goals will demonstrate your interest and enthusiasm.

- Visit the company website and social media pages

- Read industry news and articles to stay informed about current trends and challenges

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare your responses beforehand. Practice delivering clear, concise answers that highlight your skills and experience.

- Tell me about your experience operating a buckle strap drum machine

- How do you ensure the quality of the produced strap drums

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience during the interview. Quantify your accomplishments using specific examples to showcase your impact.

- Describe your experience in troubleshooting and resolving machine issues

- Provide examples of how you have implemented process improvements to enhance production efficiency

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions about the company’s growth plans, investment in technology, or any other aspects that you find intriguing.

- What are the company’s plans for expanding production capacity?

- How does the company prioritize innovation and technology adoption?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Buckle Strap Drum Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!