Are you gearing up for a career in Buffing Wheel Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Buffing Wheel Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

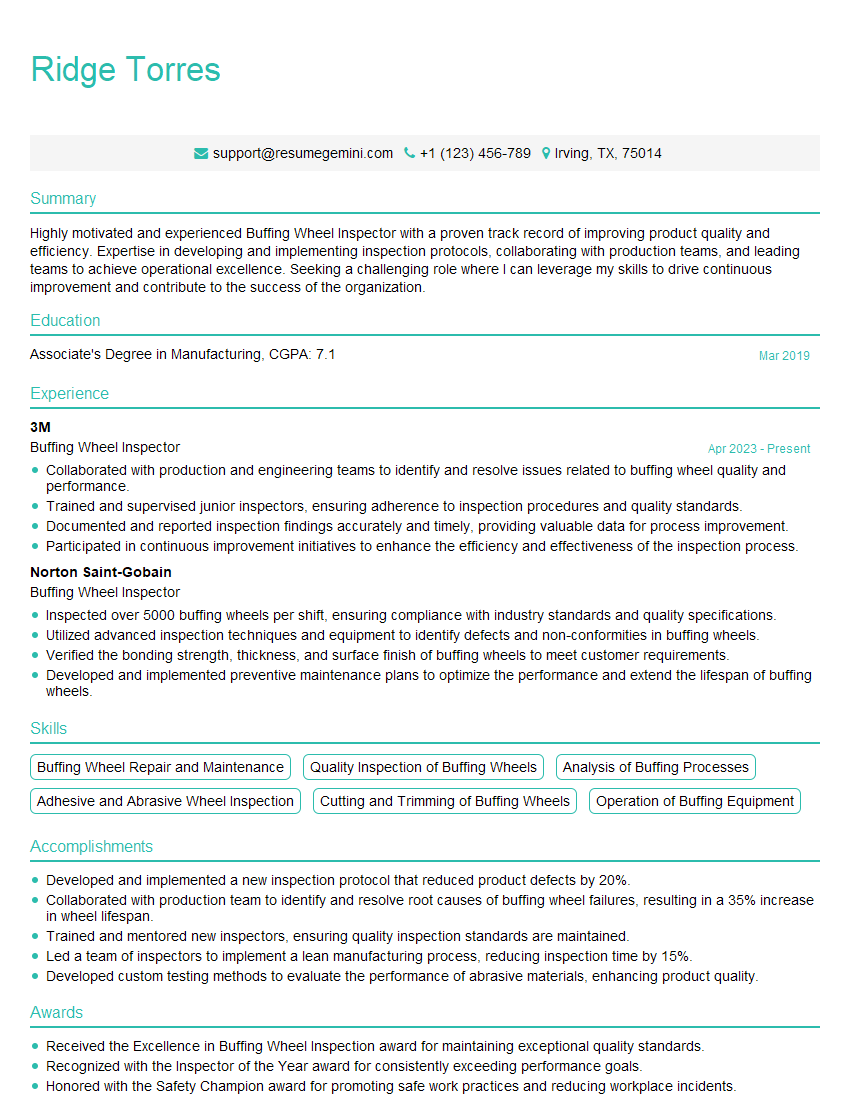

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Buffing Wheel Inspector

1. What are the key factors to consider when selecting the right type of buffing wheel?

- Material to be buffed

- Desired finish

- Speed of the buffing operation

- Size and shape of the workpiece

- Cost

2. How do you inspect buffing wheels for defects?

Visual Inspection

- Check for cracks, tears, or other damage

- Ensure the wheel is properly sewn or glued

- Verify that the wheel is balanced and not vibrating

Dimensional Inspection

- Measure the diameter, thickness, and width of the wheel

- Ensure the wheel meets the specified tolerances

3. What are the different types of buffs used in buffing?

- Sisal buffs: Used for heavy-duty cutting and cleaning

- Cotton buffs: Used for finer polishing and finishing

- Felt buffs: Used for delicate surfaces and polishing intricate shapes

- Muslin buffs: Used for polishing metal surfaces

- Cloth buffs: Used for general polishing applications

4. What are the safety precautions to follow when handling and using buffing wheels?

- Always wear eye protection

- Use a guard to prevent contact with the wheel

- Keep hands and hair away from the wheel

- Do not operate the buffing wheel at excessive speeds

- Use only the proper buffing compound for the application

5. What are the common problems that can occur with buffing wheels?

- Glazing: When the buffing compound builds up on the wheel and reduces its effectiveness

- Loading: When the buffing wheel becomes clogged with material from the workpiece

- Vibrations: When the wheel is unbalanced or not properly secured

- Cracking: When the wheel is stressed or damaged

- Tearing: When the wheel is subjected to excessive force

6. How do you maintain and store buffing wheels?

- Regularly clean the wheel with a brush or compressed air

- Inspect the wheel for defects before each use

- Store the wheel in a dry place when not in use

- Use a wheel guard to protect the wheel from damage

- Follow the manufacturer’s instructions for proper maintenance and storage

7. What are the latest advancements in buffing wheel technology?

- New materials: Graphene and diamond-impregnated buffs for enhanced cutting and polishing performance

- Automated buffing systems: Robotic arms and advanced control systems for increased productivity and consistency

- Laser-guided buffing: Precision buffing with reduced risk of damage to the workpiece

- Environmentally friendly buffs: Buffs made from recycled materials or biodegradable compounds

8. How do you troubleshoot buffing wheel problems?

- Identify the problem and its symptoms

- Inspect the wheel and equipment for any visible defects

- Check the buffing compound and its compatibility with the workpiece and wheel

- Adjust the buffing speed, pressure, and angle as needed

- Refer to the manufacturer’s instructions or consult with a qualified technician if necessary

9. What are the quality control standards for buffing wheels?

- Dimensional accuracy

- Material properties (e.g., hardness, density)

- Balance and vibration levels

- Adhesion strength (for sewn or glued wheels)

- Compliance with industry standards (e.g., ANSI, ISO)

10. How do you stay up-to-date on the latest developments in buffing wheel technology?

- Attend industry conferences and exhibitions

- Read trade publications and technical journals

- Network with other buffing professionals

- Research online and consult with industry experts

- Participate in training and certification programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Buffing Wheel Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Buffing Wheel Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Buffing Wheel Inspectors play a crucial role in quality control within manufacturing facilities. Their primary duties involve ensuring the quality and performance of buffing wheels used in various industrial applications.

1. Inspect and evaluate buffing wheels

Inspect buffing wheels for defects, damage, or non-conformities using visual inspection techniques and specialized equipment.

- Identify and measure deviations from established quality standards.

- Verify wheel dimensions, density, hardness, and other specifications.

2. Conduct performance testing

Perform performance tests to assess the effectiveness of buffing wheels in removing imperfections, creating desired finishes, and meeting production requirements.

- Evaluate factors such as cutting rate, surface finish, and wheel wear.

- Provide recommendations for optimizing buffing wheel performance.

3. Maintain quality records

Document inspection results, performance data, and any identified defects or non-conformities in detailed reports.

- Maintain records of buffing wheel specifications, usage history, and maintenance schedules.

- Analyze quality data to identify trends and areas for improvement.

4. Collaborate with production team

Work closely with the production team to provide feedback on buffing wheel quality and performance, and to resolve any issues that may arise.

- Communicate inspection results and recommendations to improve buffing processes.

- Participate in problem-solving efforts to optimize production efficiency and minimize downtime.

Interview Tips

To ace an interview for the role of Buffing Wheel Inspector, candidates should focus on highlighting their technical skills, attention to detail, and problem-solving abilities.

1. Research the company and industry

Demonstrate your knowledge of the company’s products, services, and industry trends. Research the specific application of buffing wheels within their manufacturing processes.

- Review the company website, press releases, and industry publications.

- Network with professionals in the field to gain insights into the industry and potential challenges.

2. Prepare for technical questions

Practice answering questions related to buffing wheel inspection techniques, performance testing procedures, and quality control standards. Be prepared to discuss your experience with different types of buffing wheels and their applications.

- Review industry-specific publications and training materials on buffing wheel inspection.

- Practice using specialized equipment and demonstrating your proficiency in visual inspection techniques.

3. Emphasize attention to detail

Highlight your ability to identify and measure deviations in buffing wheel quality, even under time constraints. Provide examples of how you have ensured the accuracy and consistency of your inspection findings.

- Describe your experience in using precision measuring instruments and maintaining detailed inspection records.

- Share examples of how your attention to detail has contributed to improving product quality or reducing production downtime.

4. Showcase problem-solving skills

Describe your approach to problem-solving when encountering non-conforming buffing wheels or production issues. Explain how you analyze data, identify root causes, and develop effective solutions.

- Provide examples of how you have collaborated with production engineers or quality control teams to resolve buffing-related problems.

- Explain how you have implemented process improvements based on your inspection findings and analysis.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Buffing Wheel Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!