Are you gearing up for an interview for a Bulk Filler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bulk Filler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

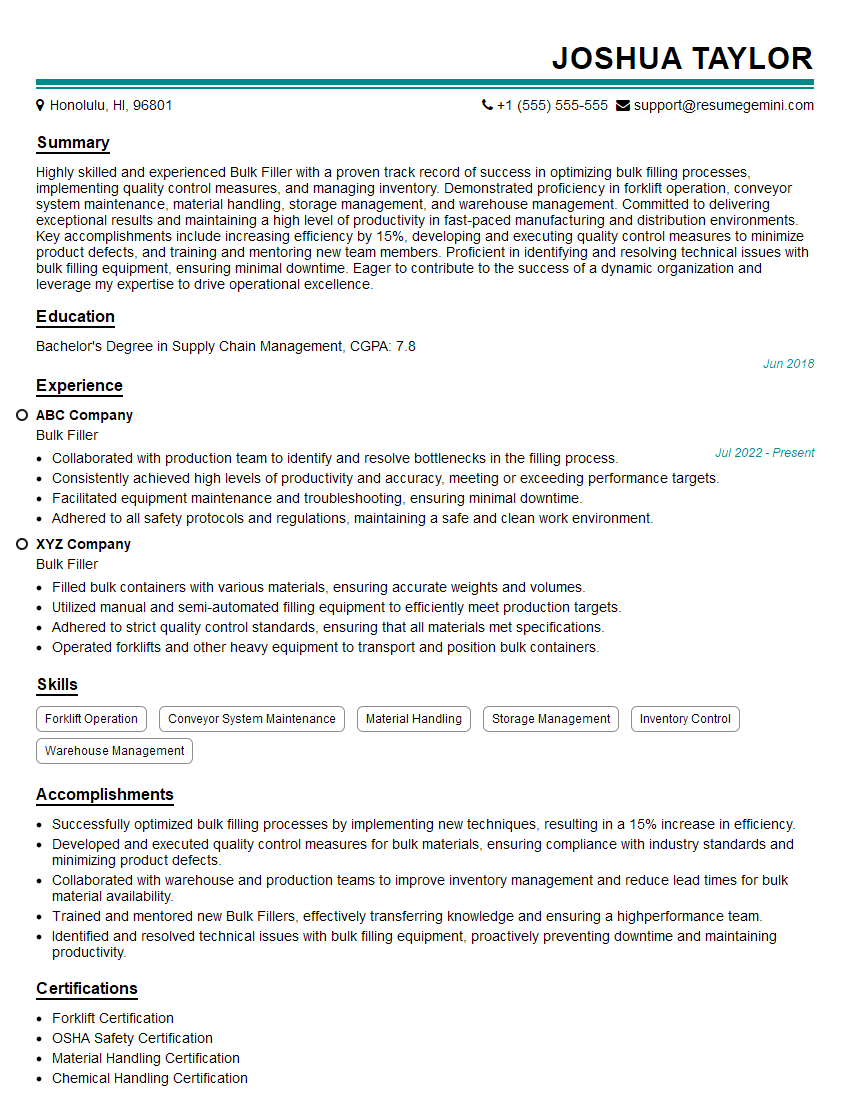

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bulk Filler

1. What are the different types of bulk fillers?

There are two main types of bulk fillers: organic and inorganic. Organic bulk fillers are made from natural materials, such as wood flour, cellulose, and starch. Inorganic bulk fillers are made from synthetic materials, such as calcium carbonate, talc, and clay.

2. What are the advantages and disadvantages of using bulk fillers?

- Advantages:

- Bulk fillers can reduce the cost of a product.

- Bulk fillers can improve the strength and stiffness of a product.

- Bulk fillers can reduce the weight of a product.

- Disadvantages:

- Bulk fillers can reduce the transparency of a product.

- Bulk fillers can make a product more brittle.

- Bulk fillers can increase the flammability of a product.

3. What are the most common applications for bulk fillers?

Bulk fillers are used in a wide variety of applications, including:

- Plastics

- Rubber

- Paper

- Paints

- Cosmetics

4. How do you select the right bulk filler for a particular application?

The selection of the right bulk filler for a particular application depends on a number of factors, including:

- The cost of the bulk filler

- The strength and stiffness of the bulk filler

- The weight of the bulk filler

- The transparency of the bulk filler

- The brittleness of the bulk filler

- The flammability of the bulk filler

5. What are the latest trends in the use of bulk fillers?

The latest trends in the use of bulk fillers include:

- The use of nano-sized bulk fillers

- The use of bio-degradable bulk fillers

- The use of recycled bulk fillers

6. What are the challenges in the use of bulk fillers?

The challenges in the use of bulk fillers include:

- The difficulty in dispersing bulk fillers evenly throughout a product

- The tendency of bulk fillers to settle out of a product

- The potential for bulk fillers to interact with other ingredients in a product

7. What are the future prospects for the use of bulk fillers?

The future prospects for the use of bulk fillers are promising. The increasing demand for lightweight and low-cost materials is driving the growth of the bulk filler market. The development of new technologies is also expected to contribute to the growth of the market.

8. What are the mechanical properties of bulk fillers?

The mechanical properties of bulk fillers vary depending on the type of filler. However, in general, bulk fillers can improve the strength, stiffness, and toughness of a material. Bulk fillers can also reduce the weight of a material.

9. What are the thermal properties of bulk fillers?

The thermal properties of bulk fillers vary depending on the type of filler. However, in general, bulk fillers can improve the thermal conductivity of a material. Bulk fillers can also reduce the thermal expansion of a material.

10. What are the electrical properties of bulk fillers?

The electrical properties of bulk fillers vary depending on the type of filler. However, in general, bulk fillers can increase the electrical conductivity of a material. Bulk fillers can also reduce the dielectric constant of a material.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bulk Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bulk Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bulk Fillers are responsible for ensuring the proper mixing and handling of large quantities of materials used in various industrial processes. They play a crucial role in maintaining the efficiency and quality of production lines.

1. Material Handling

Bulk Fillers are responsible for handling large volumes of materials, including powders, granules, and liquids. They ensure that these materials are properly stored, measured, and transferred to production equipment.

- Operate and maintain bulk material handling equipment, such as conveyors, feeders, and mixers

- Monitor material levels and ensure a sufficient supply for production

2. Mixing and Blending

Bulk Fillers are responsible for mixing and blending different materials to create the desired composition. They ensure that the materials are mixed thoroughly and meet the required specifications.

- Follow formulas and recipes to mix and blend materials accurately

- Control mixing parameters such as temperature, speed, and time

3. Quality Control

Bulk Fillers are responsible for ensuring the quality of the materials used in production. They conduct regular tests and inspections to verify that the materials meet the required specifications.

- Perform quality control tests on materials, such as moisture content, particle size, and chemical composition

- Maintain records of quality control data for future reference

4. Troubleshooting

Bulk Fillers are responsible for troubleshooting any issues that may arise during the mixing and handling of materials. They identify the cause of the problem and implement solutions to ensure the smooth operation of the production line.

- Identify and resolve problems with material handling equipment

- Adjust mixing parameters to optimize material quality

Interview Tips

Preparing for a Bulk Filler interview can help increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Bulk Filler position you are applying for. This will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company’s website to learn about their products, services, and company culture

- Read industry news and articles to stay up-to-date on the latest trends and technologies

- Prepare specific questions about the company and the position to ask during the interview

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared when it comes time for the actual interview.

- Prepare answers to questions about your experience, skills, and qualifications

- Consider potential questions about your knowledge of bulk material handling and quality control

- Practice answering questions in a clear and concise manner

3. Highlight Your Experience and Skills

During the interview, emphasize your relevant experience and skills that make you a suitable candidate for the Bulk Filler position. Provide specific examples to demonstrate your abilities.

- Discuss your experience in handling large volumes of materials and operating bulk material handling equipment

- Highlight your understanding of mixing and blending techniques and your ability to control mixing parameters

- Emphasize your ability to conduct quality control tests and maintain quality standards

4. Show Your Enthusiasm and Interest

Convey your enthusiasm for the Bulk Filler position and the opportunity to work with the company. Express your interest in the industry and your desire to contribute to the company’s success.

- Share your passion for working with bulk materials and your desire to learn more about the industry

- Discuss your interest in the company’s products or services and how your skills can contribute to the team

- Ask thoughtful questions that demonstrate your interest in the position and the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bulk Filler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!