Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bulk Pallet Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

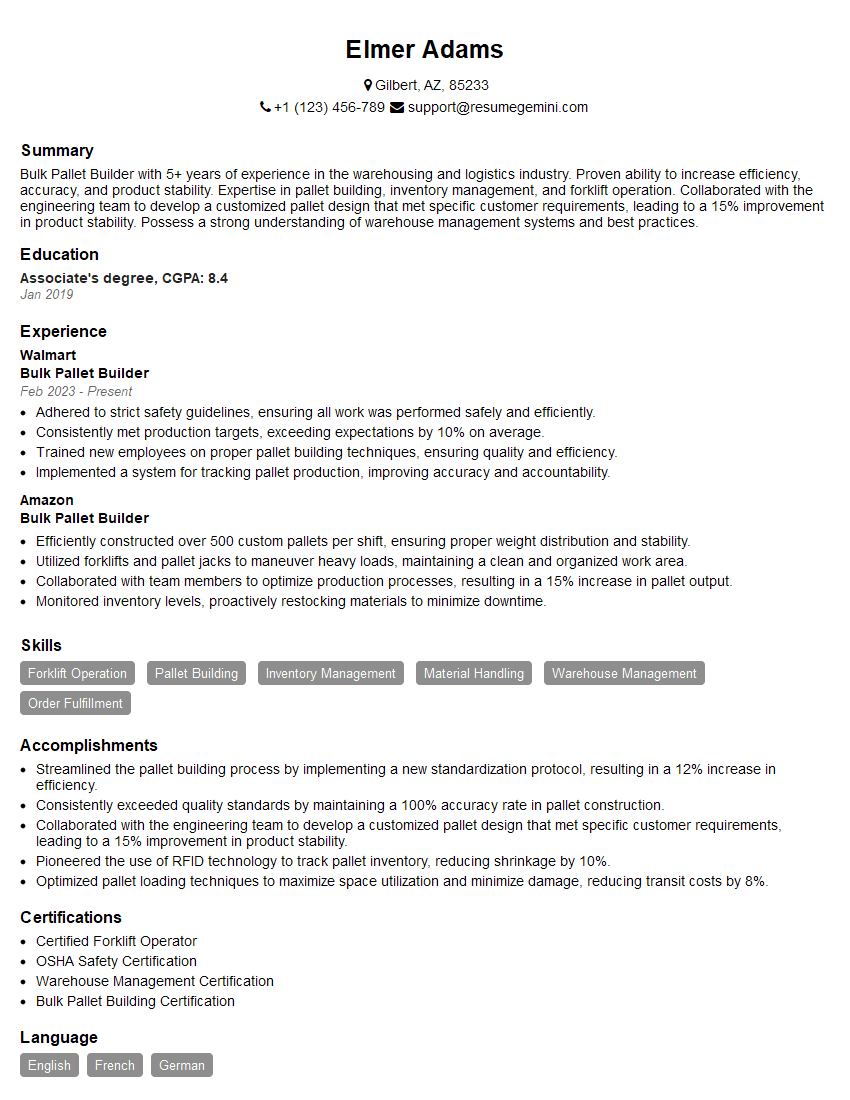

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bulk Pallet Builder

1. What are the different types of bulk pallet builders?

There are two main types of bulk pallet builders:

- Manual bulk pallet builders: These machines are operated by hand and require the operator to manually load the pallets onto the machine. They are typically used for small to medium-sized operations.

- Automatic bulk pallet builders: These machines are automated and can load pallets onto the machine without the need for an operator. They are typically used for large operations.

2. What are the factors to consider when choosing a bulk pallet builder?

Factors to consider when choosing a bulk pallet builder:

- The size of the operation: The size of the operation will determine the type of bulk pallet builder that is needed. A small operation may be able to get by with a manual bulk pallet builder, while a large operation will need an automatic bulk pallet builder.

- The type of pallets: The type of pallets that are being used will also determine the type of bulk pallet builder that is needed. Some bulk pallet builders are only designed to handle certain types of pallets.

- The budget: The budget will also play a role in the decision-making process. Manual bulk pallet builders are typically less expensive than automatic bulk pallet builders.

3. What are the advantages of using a bulk pallet builder?

There are many advantages to using a bulk pallet builder, including:

- Increased efficiency: Bulk pallet builders can significantly increase the efficiency of the palletizing process. They can load pallets much faster than manual labor, which can save time and money.

- Reduced labor costs: Bulk pallet builders can also help to reduce labor costs. They can eliminate the need for manual labor to load pallets, which can free up workers for other tasks.

- Improved safety: Bulk pallet builders can also help to improve safety in the workplace. They can eliminate the risk of injuries that can occur when manual labor is used to load pallets.

4. What are the disadvantages of using a bulk pallet builder?

There are also some disadvantages to using a bulk pallet builder, including:

- High cost: Bulk pallet builders can be expensive to purchase and maintain. This can make them a prohibitive option for some businesses.

- Limited flexibility: Bulk pallet builders are not as flexible as manual labor. They can only be used to load pallets of a certain size and weight. This can make them unsuitable for some businesses.

5. What are the key features to look for in a bulk pallet builder?

When choosing a bulk pallet builder, it is important to look for the following key features:

- Speed: The speed of the bulk pallet builder is important. It should be able to load pallets quickly and efficiently.

- Reliability: The bulk pallet builder should be reliable and able to withstand heavy use. It should also be easy to maintain.

- Safety: The bulk pallet builder should be safe to use. It should have features that protect the operator from injuries.

6. How do you troubleshoot a bulk pallet builder?

There are a few common problems that can occur with bulk pallet builders. These problems can usually be solved by following these troubleshooting tips:

- Check the power supply: Make sure that the bulk pallet builder is properly plugged into a power outlet.

- Check the fuses: If the bulk pallet builder is not receiving power, check the fuses. If a fuse is blown, replace it with a new fuse of the same amperage.

- Check the sensors: The bulk pallet builder has sensors that detect the presence of pallets. If the sensors are not working properly, the bulk pallet builder will not be able to load pallets.

- Check the conveyor belt: The conveyor belt is responsible for transporting pallets into the bulk pallet builder. If the conveyor belt is not working properly, the bulk pallet builder will not be able to load pallets.

7. What are the maintenance requirements for a bulk pallet builder?

Bulk pallet builders require regular maintenance to keep them running properly. This maintenance includes:

- Cleaning: The bulk pallet builder should be cleaned regularly to remove dust and debris. This will help to prevent the bulk pallet builder from malfunctioning.

- Lubrication: The bulk pallet builder should be lubricated regularly to keep the moving parts running smoothly. This will help to extend the life of the bulk pallet builder.

- Inspection: The bulk pallet builder should be inspected regularly for any signs of damage. If any damage is found, it should be repaired immediately.

8. What are the safety precautions that should be taken when using a bulk pallet builder?

The following safety precautions should be taken when using a bulk pallet builder:

- Wear appropriate safety gear: When using a bulk pallet builder, it is important to wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

- Keep hands clear of moving parts: Keep your hands clear of all moving parts of the bulk pallet builder. This will help to prevent injuries.

- Do not overload the bulk pallet builder: Do not overload the bulk pallet builder. This can cause the bulk pallet builder to malfunction and could lead to injuries.

- Be aware of your surroundings: Be aware of your surroundings when using a bulk pallet builder. This will help to prevent accidents.

9. What are the different types of pallets that can be used with a bulk pallet builder?

There are a variety of different types of pallets that can be used with a bulk pallet builder. These pallets include:

- Wood pallets: Wood pallets are the most common type of pallet. They are made from wood and are available in a variety of sizes and weights.

- Plastic pallets: Plastic pallets are made from plastic and are lightweight and durable. They are also resistant to moisture and chemicals.

- Metal pallets: Metal pallets are made from metal and are very strong and durable. They are also resistant to fire and moisture.

10. What are the benefits of using a bulk pallet builder?

There are many benefits to using a bulk pallet builder. These benefits include:

- Increased productivity: Bulk pallet builders can help to increase productivity by speeding up the palletizing process.

- Reduced labor costs: Bulk pallet builders can help to reduce labor costs by eliminating the need for manual labor to load pallets.

- Improved safety: Bulk pallet builders can help to improve safety in the workplace by eliminating the risk of injuries that can occur when manual labor is used to load pallets.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bulk Pallet Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bulk Pallet Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bulk Pallet Builders are responsible for building and assembling pallets to store and transport products. It involves working with heavy materials and machinery, which requires both physical strength and attention to detail. The key responsibilities of a Bulk Pallet Builder include:

1. Pallet Assembly

Assembling pallets according to specifications, using a variety of tools and equipment, including nail guns, saws, and drills.

- Interpreting and following production orders and blueprints.

- Selecting and preparing appropriate materials, such as wood, nails, and glue.

2. Pallet Repair

Inspecting and repairing damaged pallets to ensure their safety and functionality.

- Identifying and assessing damage, such as broken boards, loose nails, or warped wood.

- Repairing pallets by replacing damaged components, reinforcing weak areas, or treating rot and decay.

3. Machine Operation

Operating machinery, such as conveyor belts, automated nailing machines, and forklifts, to streamline the pallet-building process.

- Loading and unloading materials and finished pallets onto and off conveyors.

- Setting up and adjusting machine parameters to meet production requirements.

4. Quality Control

Inspecting and ensuring the quality of pallets before they are shipped to customers.

- Verifying that pallets meet specifications for size, weight, strength, and durability.

- Rejecting or repairing pallets that do not meet quality standards.

Interview Tips

Preparing for a Bulk Pallet Builder interview requires a combination of technical knowledge, physical fitness, and enthusiasm for hands-on work. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, industry, and products. Understand the specific responsibilities of the Bulk Pallet Builder position and how it fits into the company’s operations.

- Check the company website, LinkedIn profile, and industry publications.

- Read the job description carefully and identify the key skills and experience required.

2. Highlight Your Physical Capabilities

Emphasize your physical strength, endurance, and ability to perform repetitive tasks. Mention any previous experience in physically demanding roles or sports.

- Provide examples of how you have handled heavy objects or operated machinery safely and efficiently.

- Be prepared to discuss your fitness level and ability to work in a fast-paced environment.

3. Demonstrate Attention to Detail

Show that you are meticulous and have a strong eye for detail. Highlight your ability to follow instructions precisely and ensure accuracy in your work.

- Provide examples of tasks where you have demonstrated a high level of attention to detail.

- Explain how you stay organized and manage multiple tasks effectively.

4. Show Enthusiasm for Manual Labor

Convey your willingness and eagerness to engage in physical labor. Explain your interest in the pallet-building process and your motivation to contribute to the company’s production goals.

- Share your experiences with manual labor or hobbies that demonstrate your physical capabilities and work ethic.

- Express your enthusiasm for learning new skills and working as part of a team.

Next Step:

Now that you’re armed with the knowledge of Bulk Pallet Builder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bulk Pallet Builder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini