Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bulk Plant Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

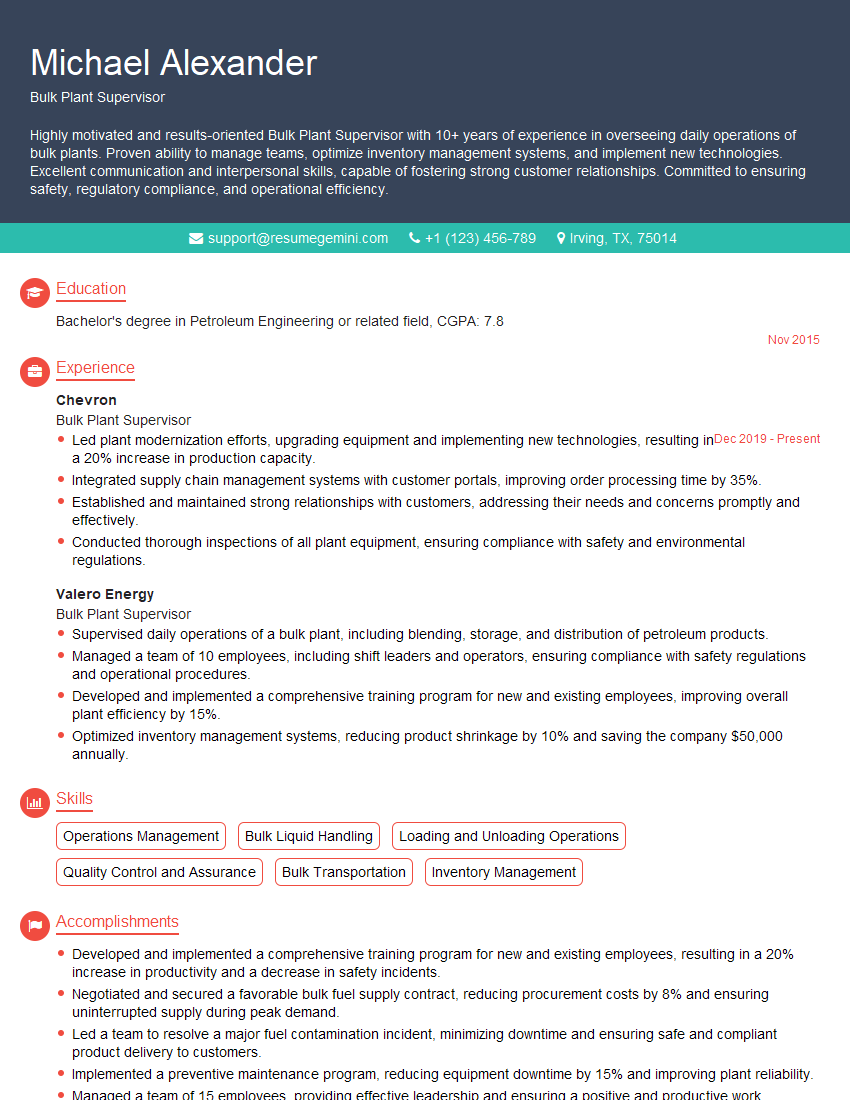

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bulk Plant Supervisor

1. Explain the key responsibilities of a Bulk Plant Supervisor?

As a Bulk Plant Supervisor, my primary responsibilities include:

- Overseeing the safe and efficient operation of the bulk plant, ensuring compliance with regulations and company policies.

- Managing plant inventory, coordinating deliveries, and ensuring product quality.

- Supervising a team of plant operators and drivers, training and developing them.

- Developing and implementing safety protocols, conducting safety audits, and maintaining a safe and secure work environment.

- Monitoring plant equipment, performing preventive maintenance, and troubleshooting technical issues.

2. Describe the storage and handling procedures for petroleum products at a bulk plant.

Storage Management

- Properly storing products in designated tanks, ensuring compatibility and segregation.

- Maintaining tank integrity, monitoring levels, and performing regular inspections.

- Implementing spill prevention and containment measures, including spill kits and containment berms.

Handling Procedures

- Safely transferring products through pipelines, pumps, and hoses.

- Inspecting and maintaining loading equipment, including pumps and meters.

- Ensuring proper grounding and bonding during loading and unloading operations.

3. How do you ensure product quality and prevent contamination at a bulk plant?

Ensuring product quality and preventing contamination is crucial. My approach involves:

- Regularly testing and monitoring product quality using industry-standard methods.

- Maintaining a clean and organized plant, minimizing the risk of contaminants.

- Inspecting equipment and pipelines periodically to detect any potential sources of contamination.

- Implementing strict loading and unloading procedures to prevent cross-contamination.

- Training employees on proper handling techniques and hygiene practices.

4. What safety measures are essential for a bulk plant operation?

Safety is paramount in a bulk plant environment. I prioritize the following measures:

- Establishing and enforcing clear safety policies and procedures.

- Providing comprehensive safety training to all employees.

- Conducting regular safety audits and inspections to identify and mitigate hazards.

- Implementing emergency response plans and training employees on their roles.

- Promoting a culture of safety awareness and vigilance among the team.

5. Explain how you would manage a team of plant operators and drivers.

Effective team management is key. My approach includes:

- Setting clear expectations and performance standards.

- Providing regular feedback, guidance, and support to team members.

- Recognizing and rewarding positive contributions.

- Promoting teamwork and collaboration through open communication.

- Resolving conflicts and addressing performance issues promptly and fairly.

6. Describe the challenges and opportunities in the role of a Bulk Plant Supervisor.

Challenges

- Ensuring product quality and regulatory compliance in a demanding environment.

- Managing a team of employees with diverse backgrounds and skills.

- Responding effectively to emergencies and unplanned events.

Opportunities

- Playing a vital role in the supply chain and distribution of essential products.

- Developing and implementing innovative solutions to optimize operations.

- Growing professionally and advancing in the industry.

7. What are the key performance indicators (KPIs) used to evaluate the performance of a Bulk Plant Supervisor?

- Product quality and compliance

- Operational efficiency (e.g., throughput, inventory levels)

- Safety record and adherence to regulations

- Team performance and development

- Customer satisfaction and timely delivery

8. Describe your experience in managing bulk plant equipment, including loading and unloading operations.

Throughout my career, I have gained extensive experience in managing bulk plant equipment and ensuring efficient loading and unloading operations. My responsibilities included:

- Overseeing the operation and maintenance of storage tanks, pumps, pipelines, and loading arms.

- Coordinating with drivers and customers to ensure smooth and timely deliveries.

- Implementing and enforcing safety protocols during loading and unloading activities.

- Troubleshooting and resolving equipment malfunctions to minimize downtime.

- Conducting regular inspections and preventive maintenance to ensure equipment reliability.

9. Explain how you would handle a customer complaint about product quality or delivery issues.

Handling customer complaints promptly and effectively is crucial. My approach involves:

- Actively listening and empathizing with the customer.

- Investigating the issue thoroughly to determine the root cause.

- Providing a clear and timely explanation of the situation to the customer.

- Collaborating with relevant departments to resolve the issue promptly.

- Following up with the customer to ensure satisfaction.

10. How do you stay updated on industry best practices and regulations related to bulk plant operations?

To stay current with industry best practices and regulations, I actively engage in:

- Attending industry conferences and workshops.

- Subscribing to industry publications and newsletters.

- Participating in online forums and discussion groups.

- Collaborating with industry experts and consultants.

- Reviewing and analyzing industry reports and white papers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bulk Plant Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bulk Plant Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Bulk Plant Supervisor is a crucial role within the organization, responsible for ensuring the smooth and efficient operation of the bulk plant. Their primary responsibilities encompass overseeing all aspects of the facility’s day-to-day activities, including production, storage, and distribution of petroleum products.

1. Production Management

The Supervisor is tasked with planning and executing production schedules to meet customer demands while adhering to safety protocols and regulatory compliance. Key responsibilities include:

- Develop and implement production plans to optimize output and minimize costs.

- Monitor and adjust production processes to ensure product quality and efficiency.

- Troubleshoot and resolve production issues to maintain uninterrupted operations.

2. Storage and Inventory Control

The Supervisor is accountable for the proper storage and management of petroleum products, ensuring their quality and minimizing losses. Responsibilities include:

- Implement and maintain inventory control systems to track stock levels and prevent shortages.

- Conduct regular inspections and testing to ensure product integrity and compliance with safety standards.

- Oversee product loading and unloading operations to prevent spills and contamination.

3. Distribution Management

The Supervisor coordinates and manages the distribution of petroleum products to customers, ensuring timely and efficient delivery. Responsibilities include:

- Plan and schedule deliveries to meet customer requirements and optimize fleet utilization.

- Manage customer orders, track shipments, and resolve any delivery issues promptly.

- Supervise drivers and ensure compliance with safety regulations and company policies.

4. Safety and Compliance

The Supervisor is ultimately responsible for ensuring a safe and compliant work environment. Key responsibilities include:

- Develop and implement safety programs and procedures to prevent accidents and injuries.

- Conduct regular safety inspections and audits to identify potential hazards and ensure compliance with regulations.

- Train and supervise employees on safety practices and emergency response procedures.

Interview Preparation Tips

To ace an interview for the Bulk Plant Supervisor position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some essential interview preparation tips:

1. Research the Company and Industry

Familiarize yourself with the organization’s history, mission, and values. Research the petroleum industry and stay abreast of current trends and challenges.

- Visit the company’s website and social media pages.

- Read industry publications and articles to gain insights into the market.

2. Highlight Relevant Experience and Skills

Emphasize your experience in bulk plant operations, production management, and safety compliance. Showcase your ability to lead and motivate teams, manage inventory, and resolve complex issues.

- Quantify your accomplishments with specific metrics and examples.

- Be prepared to discuss your expertise in industry software and technologies.

3. Prepare for Technical Questions

Expect technical questions related to petroleum storage and distribution. Be prepared to demonstrate your understanding of product safety, storage requirements, and emergency procedures.

- Review industry standards and regulations related to bulk plant operations.

- Practice calculating inventory levels and managing distribution schedules.

4. Emphasize Safety and Compliance

Highlight your commitment to safety and your ability to create and maintain a safe work environment. Explain how you would develop and implement safety programs and ensure compliance with industry regulations.

- Discuss your experience in conducting safety inspections and training employees on safety protocols.

- Demonstrate your understanding of risk assessment and emergency response procedures.

5. Prepare Questions for the Interviewer

It is a good practice to prepare thoughtful questions to ask the interviewer. This shows your engagement and interest in the role and the organization.

- Ask about the company’s growth plans and industry outlook.

- Inquire about specific challenges or opportunities the bulk plant is facing.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bulk Plant Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bulk Plant Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.