Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bull Riveter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bull Riveter so you can tailor your answers to impress potential employers.

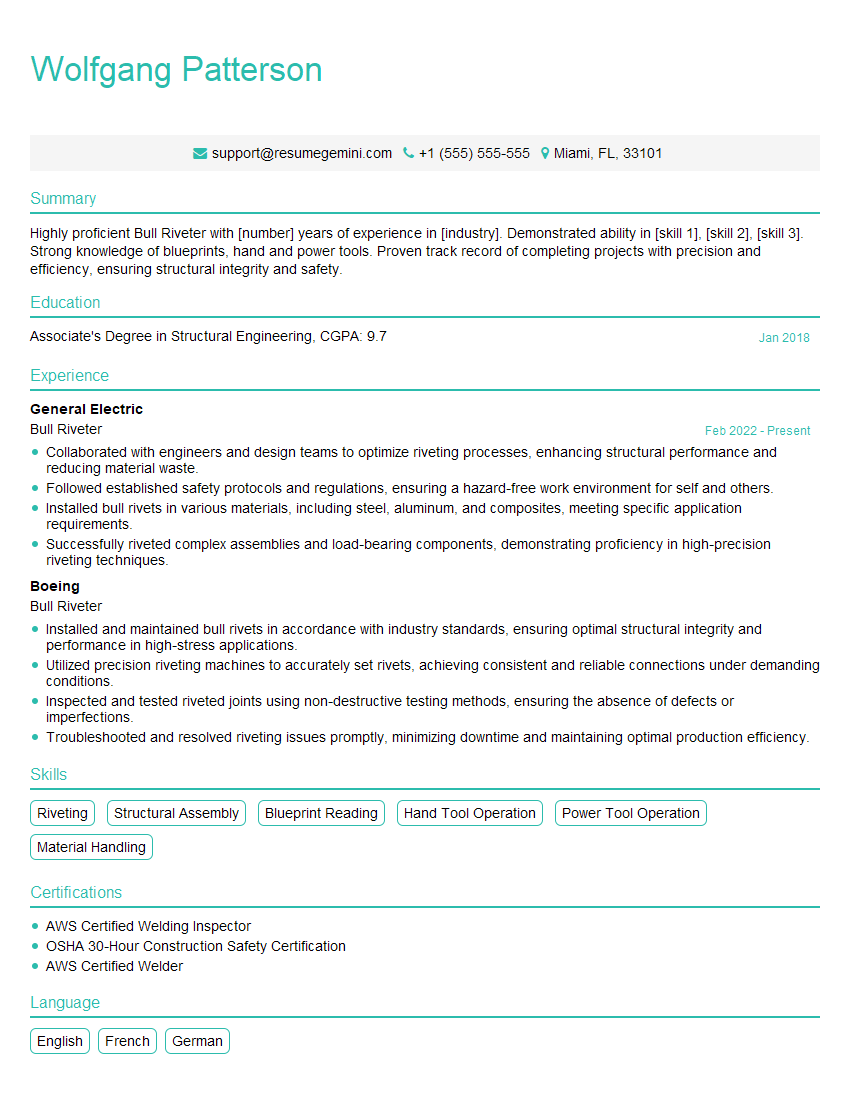

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bull Riveter

1. What is the difference between a rivet gun and a rivet hammer?

A rivet gun is a power tool that uses compressed air or electricity to drive rivets, while a rivet hammer is a hand tool that uses manual force to drive rivets.

- Rivet guns are faster and more powerful than rivet hammers, but they are also more expensive and require special training to operate.

- Rivet hammers are less expensive and easier to use than rivet guns, but they are slower and less powerful.

- The type of rivet gun or rivet hammer that you use will depend on the specific application and the materials that you are working with.

2. What are the different types of rivets?

There are many different types of rivets, each with its own unique purpose and application.

Solid Rivets

- Solid rivets are the most common type of rivet and are made from a single piece of metal.

- They are strong and durable, but they can be difficult to install and remove.

Tubular Rivets

- Tubular rivets are made from a hollow tube of metal.

- They are easier to install and remove than solid rivets, but they are not as strong.

Blind Rivets

- Blind rivets are designed to be installed from one side of the material.

- They are often used in applications where it is difficult or impossible to access both sides of the material.

3. What are the different materials that rivets can be made from?

Rivets can be made from a variety of materials, including:

- Steel

- Aluminum

- Copper

- Brass

- Stainless steel

The material that you choose for your rivets will depend on the specific application and the materials that you are working with.

4. What are the different sizes of rivets?

Rivets come in a variety of sizes, from small rivets that are used in delicate applications to large rivets that are used in heavy-duty applications.

The size of the rivet that you choose will depend on the specific application and the materials that you are working with.

5. How do you choose the right rivet for a particular application?

There are several factors to consider when choosing the right rivet for a particular application:

- The type of material that you are working with

- The thickness of the material

- The strength of the joint

- The environment in which the joint will be used

Once you have considered these factors, you can choose the right rivet for your application.

6. How do you install a rivet?

There are several different ways to install a rivet, depending on the type of rivet that you are using.

In general, the steps involved in installing a rivet are as follows:

- Drill a hole in the material

- Insert the rivet into the hole

- Set the rivet using a rivet gun or rivet hammer

For more specific instructions on how to install a rivet, refer to the manufacturer’s instructions.

7. How do you remove a rivet?

There are several different ways to remove a rivet, depending on the type of rivet that you are using.

In general, the steps involved in removing a rivet are as follows:

- Drill a hole in the head of the rivet

- Split the rivet head using a rivet splitter or a chisel

- Remove the rivet shank

For more specific instructions on how to remove a rivet, refer to the manufacturer’s instructions.

8. What are the safety precautions that should be taken when working with rivets?

There are several safety precautions that should be taken when working with rivets:

- Wear safety glasses

- Wear gloves

- Use a rivet gun or rivet hammer that is in good condition

- Do not point the rivet gun or rivet hammer at anyone

- Keep your hands clear of the rivet gun or rivet hammer

- Do not use rivets that are damaged or deformed

9. What are the common mistakes that people make when working with rivets?

There are several common mistakes that people make when working with rivets:

- Using the wrong size rivet

- Using the wrong type of rivet

- Not using enough rivets

- Not setting the rivets properly

- Not taking the proper safety precautions

By avoiding these common mistakes, you can ensure that your rivet joints are strong and durable.

10. What are the applications of rivets?

Rivets are used in a wide variety of applications, including:

- Construction

- Manufacturing

- Transportation

- Aerospace

- Electronics

Rivets are used to join two or more pieces of material together, creating a strong and durable bond.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bull Riveter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bull Riveter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bull Riveters are responsible for installing and tightening rivets in metal structures, such as bridges, buildings, and ships.

1. Installing Rivets

Bull Riveters use a specialized tool called a rivet gun to install rivets. Rivets are small, headless nails that are used to join two pieces of metal together. The Riveter inserts the rivet into the hole and then uses the rivet gun to squeeze the rivet into place, creating a strong and permanent bond.

2. Tightening Rivets

After the rivets have been installed, the Bull Riveter must tighten them. This is done using a special wrench called a rivet wrench. The Riveter tightens the rivet until it is snug, but not so tight that it breaks.

3. Inspecting Rivets

Once the rivets have been installed and tightened, the Bull Riveter must inspect them to ensure that they are properly seated and that there are no cracks or other defects. The Riveter may use a magnifying glass or other tools to help with the inspection.

4. Troubleshooting

Bull Riveters must be able to troubleshoot any problems that may occur during the riveting process. For example, the Riveter may need to adjust the settings on the rivet gun or replace a worn-out rivet. The Riveter must also be able to identify and fix any problems with the metal structure being riveted.

Interview Tips

Preparing for an interview for a Bull Riveter position can be daunting, but with the right tips and preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand the company’s culture, values, and goals. You can find information about the company on their website, social media pages, and in news articles.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked during an interview for a Bull Riveter position. These questions include:

- Tell me about your experience with riveting.

- What are your strengths and weaknesses as a Bull Riveter?

- Why are you interested in this position?

- What are your salary expectations?

Take some time to practice answering these questions in advance. This will help you feel more confident and prepared during your interview.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing any clothing that is too revealing or casual.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Arrive for your interview on time, or even a few minutes early. If you are running late, be sure to call or email the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bull Riveter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!