Are you gearing up for an interview for a Bullard Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bullard Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

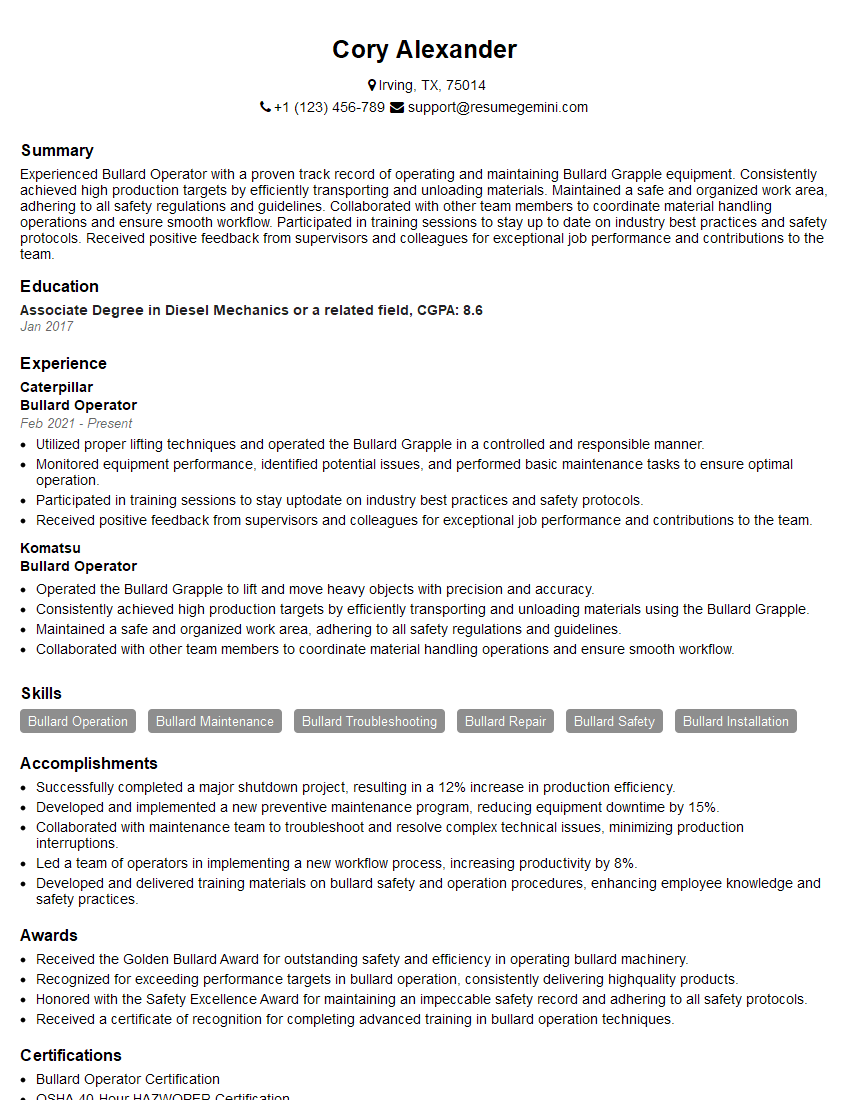

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bullard Operator

1. What are the key responsibilities of a Bullard Operator?

The primary responsibilities of a Bullard Operator include:

- Monitoring and controlling all aspects of the bullard machine, including speed, feed, and cutting depth.

- Ensuring that the bullard machine is properly set up and maintained.

- Producing high-quality parts that meet customer specifications.

- Troubleshooting and resolving any issues that may arise during operation.

- Adhering to all safety regulations and procedures.

2. What are the different types of bullard machines?

Vertical Bullard

- Used for facing, boring, turning, drilling, and milling operations.

- Has a vertical spindle that rotates the workpiece.

Horizontal Bullard

- Used for heavy-duty turning and boring operations.

- Has a horizontal spindle that rotates the workpiece.

Chucking Bullard

- Used for high-volume production of small parts.

- Has a chuck that holds the workpiece.

3. What are the safety precautions that must be followed when operating a bullard machine?

The following safety precautions must be followed when operating a bullard machine:

- Wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs.

- Ensure that the machine is properly grounded.

- Keep the work area clean and free of debris.

- Never operate the machine while under the influence of alcohol or drugs.

- Follow all manufacturer’s instructions for safe operation.

4. What are the common problems that can occur when operating a bullard machine?

Some common problems that can occur when operating a bullard machine include:

- Vibration: This can be caused by an unbalanced workpiece, worn bearings, or misalignment.

- Chatter: This is a high-pitched noise that can be caused by a dull cutting tool or an unstable workpiece.

- Overheating: This can be caused by excessive friction or a lack of lubrication.

- Tool breakage: This can be caused by a dull cutting tool, an improper cutting speed, or an excessive feed rate.

5. How do you troubleshoot a bullard machine?

To troubleshoot a bullard machine, you can follow these steps:

- Identify the problem: Observe the symptoms and try to identify the root cause.

- Check the basics: Ensure that the machine is properly grounded, the workpiece is securely clamped, and the cutting tool is sharp.

- Refer to the manufacturer’s manual: Consult the manual for specific troubleshooting tips.

- Contact a qualified technician: If you are unable to resolve the problem yourself, contact a qualified technician for assistance.

6. What are the different types of cutting tools that can be used on a bullard machine?

The following types of cutting tools can be used on a bullard machine:

- Boring tools: Used for enlarging holes.

- Facing tools: Used for creating flat surfaces.

- Turning tools: Used for reducing the diameter of a workpiece.

- Drilling tools: Used for creating holes.

- Milling tools: Used for creating complex shapes.

7. What are the different types of materials that can be machined on a bullard machine?

A bullard machine can be used to machine a wide range of materials, including:

- Metals: Such as steel, aluminum, and cast iron.

- Plastics: Such as acrylic and polycarbonate.

- Wood: Such as mahogany and oak.

- Composite materials: Such as fiberglass and carbon fiber.

8. What are the advantages of using a bullard machine?

Bullard machines offer several advantages, including:

- Versatility: Bullard machines can be used for a wide range of operations, including facing, boring, turning, drilling, and milling.

- Accuracy: Bullard machines are precision machines that can produce parts with high accuracy and repeatability.

- Efficiency: Bullard machines are fast and efficient, which can help to reduce production time.

- Durability: Bullard machines are built to last and can withstand heavy use.

9. What are the disadvantages of using a bullard machine?

Bullard machines also have some disadvantages, including:

- Cost: Bullard machines can be expensive to purchase and maintain.

- Complexity: Bullard machines can be complex to operate, which requires skilled operators.

- Size: Bullard machines can be large and take up a lot of space.

- Noise: Bullard machines can be noisy during operation.

10. What is the future of bullard machines?

The future of bullard machines looks bright. Advances in technology are making bullard machines more versatile, accurate, and efficient than ever before. Bullard machines are also becoming more affordable, which is making them more accessible to small businesses and startups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bullard Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bullard Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bullard Operators are responsible for operating and maintaining bulldozers, used in a variety of industries such as construction, mining, and forestry. The primary duties include:

1. Site Preparation and Excavation

Preparing and leveling land for construction, grading slopes, and digging trenches for foundations, pipelines, and other structures.

- Clearing vegetation, removing debris, and leveling the ground.

- Excavating soil, rock, and other materials to create trenches, foundations, and slopes.

2. Material Handling

Moving, loading, and unloading materials such as earth, gravel, and debris, using the bulldozer’s blade and attachments.

- Transporting materials across job sites, loading into dump trucks, and unloading them at designated locations.

- Using attachments such as rakes, blades, and rippers for specific tasks like spreading materials or breaking up hard surfaces.

3. Equipment Maintenance

Ensuring the bulldozer is in good working order by performing regular inspections, maintenance, and repairs.

- Checking fluid levels, changing filters, and lubricating moving parts.

- Identifying and resolving mechanical issues, making necessary repairs.

4. Safety and Compliance

Adhering to all safety regulations and industry standards, ensuring the safety of themselves and others on the job site.

- Wearing appropriate safety gear and following all established protocols.

- Inspecting the work area before starting operations and reporting any hazards or potential risks.

Interview Tips

To ace an interview for a Bullard Operator position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company you’re applying to and the specific role you’re interviewing for. This will help you understand their industry, values, and the expectations for the position.

- Visit the company’s website, read their mission statement and recent press releases.

- Look up industry-related news and articles to demonstrate your knowledge of the field.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience in operating bulldozers and other heavy machinery. Quantify your accomplishments whenever possible and provide specific examples of your work.

- Discuss your experience in site preparation, excavation, material handling, and equipment maintenance.

- Mention any certifications or training you have received in operating bulldozers.

3. Demonstrate Safety Awareness

Convey your strong commitment to safety by highlighting your knowledge of industry regulations and your track record of safe work practices.

- Describe your experience in identifying and mitigating potential hazards on a job site.

- Mention your willingness to undergo safety training and follow all established protocols.

4. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you articulate your thoughts clearly and confidently.

- Prepare for questions about your experience, skills, and safety practices.

- Consider potential situational questions and develop examples to support your answers.

5. Dress Professionally

First impressions matter, so dress professionally for your interview. This shows respect for the interviewer and company, and conveys a sense of professionalism.

- Wear clean, pressed clothing that is appropriate for the industry and job role.

- Consider wearing safety boots or work attire if appropriate.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bullard Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bullard Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.