Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bulldozer Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

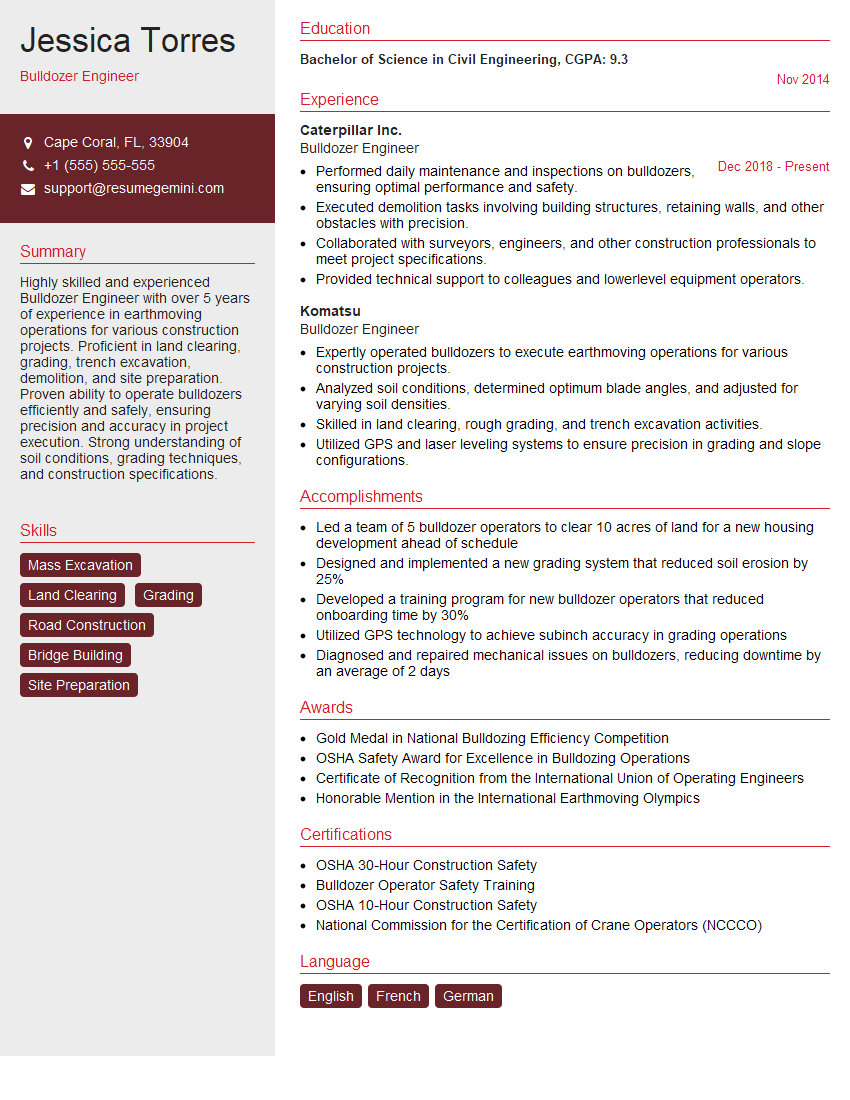

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bulldozer Engineer

1. What are the key factors to consider when operating a bulldozer on a slope?

- Slope angle and stability

- Ground conditions and surface traction

- Bulldozer weight, balance, and stability

- Visibility and communication with spotters

- Weather conditions and potential hazards

2. How do you determine the appropriate blade angle for different soil conditions?

Soil Conditions

- Loose soil: Use a flatter blade angle (30-45 degrees) for maximum penetration

- Hard soil: Use a steeper blade angle (45-60 degrees) to break through the surface

- Wet soil: Use a slightly steeper blade angle (40-50 degrees) for better traction

Blade Angle

- Flatter blade angle: More penetration, less rolling resistance

- Steeper blade angle: Less penetration, more rolling resistance

3. Describe the different types of bulldozer blades and their applications

- Straight blade: General purpose, for clearing and leveling

- Angle blade: For moving materials sideways and creating slopes

- U-blade: For pushing and grading large amounts of material

- C-blade: For clearing and piling materials, such as snow

4. How do you maintain and troubleshoot a bulldozer’s hydraulic system?

- Regularly checking and changing hydraulic fluid and filters

- Inspecting hoses, lines, and fittings for leaks or damage

- Monitoring hydraulic pressure and temperature gauges

- Testing and adjusting hydraulic controls for proper operation

- Troubleshooting common hydraulic problems, such as leaks, overheating, or loss of power

5. What are the safety precautions to observe when operating a bulldozer around other equipment and workers?

- Maintain clear visibility and communication

- Stay alert to other equipment and personnel

- Use hand signals or spotters when necessary

- Respect the operating space of other equipment

- Avoid sudden movements or maneuvers

6. How do you plan and execute an excavation project using a bulldozer?

- Assessing site conditions and determining excavation requirements

- Selecting the appropriate bulldozer and equipment

- Marking out excavation boundaries and establishing a work plan

- Operating the bulldozer safely and efficiently to remove material

- Ensuring proper disposal or stockpiling of excavated material

- Compacting and grading the excavated area as needed

7. What are the common challenges faced when operating a bulldozer and how do you overcome them?

- Slope stability: Use proper grading techniques and avoid overloading the bulldozer

- Wet or muddy conditions: Install ground mats or use wider tracks for better traction

- Obstructions or debris: Clear the area or use a grapple attachment to remove obstacles

- Equipment breakdowns: Perform regular maintenance and carry essential tools for minor repairs

- Visibility limitations: Use mirrors, cameras, or spotters for extended visibility

8. Describe the role of technology in modern bulldozer operations

- GPS and laser guidance systems for precise grading and excavation

- Machine control systems for automated operation and increased efficiency

- Load-sensing hydraulics for improved power and control

- Remote monitoring and diagnostics for real-time performance analysis

- Smart blades with integrated sensors for enhanced accuracy and productivity

9. How do you stay updated with the latest advancements and best practices in bulldozer operation?

- Attend industry conferences and workshops

- Read trade publications and technical manuals

- Network with other bulldozer operators and industry professionals

- Participate in online forums and discussions

- Obtain certifications or training in specialized techniques

10. What are your career goals and how does this role align with your aspirations?

- Express interest in the company and the role

- Highlight skills and experience relevant to the position

- Explain how the role fits into your long-term career goals

- Demonstrate enthusiasm for learning and professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bulldozer Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bulldozer Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bulldozer Engineers are highly skilled professionals responsible for operating and maintaining bulldozers in various construction and mining environments. They play a crucial role in site preparation, excavation, and earthmoving operations.

1. Equipment Operation

Skilled in operating bulldozers of various sizes and types, including crawler dozers, wheel dozers, and specialized models.

- Execute earthmoving tasks according to project specifications, including excavation, grading, backfilling, and trenching.

- Control bulldozer movements with precision and accuracy, ensuring efficient and safe operations.

2. Equipment Maintenance

Perform regular maintenance and inspections of bulldozers to ensure optimal functionality and safety.

- Identify and resolve mechanical issues, performing basic repairs and troubleshooting.

- Keep detailed records of maintenance activities, repairs, and equipment conditions.

3. Site Preparation

Prepare construction sites by clearing vegetation, removing debris, and leveling the ground.

- Interpret site plans and specifications to determine grading requirements and excavation depths.

- Collaborate with engineers and other site personnel to ensure proper site preparation.

4. Collaboration and Safety

Work closely with project managers, engineers, and other team members to coordinate earthmoving operations.

- Follow all safety protocols and regulations related to bulldozer operation and site work.

- Promote a safe work environment for themselves and others on the construction site.

Interview Tips

Preparing for a Bulldozer Engineer interview requires a combination of technical knowledge, practical experience, and strong communication skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Demonstrate your interest in the company and its projects by researching their website, industry news, and recent developments.

2. Highlight Relevant Experience

Emphasize your hands-on experience in operating bulldozers, including specific examples of projects you have worked on.

3. Demonstrate Equipment Knowledge

Show your understanding of bulldozer mechanics, hydraulics, and electrical systems. Discuss your troubleshooting and repair skills.

4. Elaborate on Safety Practices

Highlight your commitment to safety by describing your adherence to industry regulations and your personal safety protocols.

5. Prepare for Technical Questions

Be ready to answer questions about bulldozer operation, maintenance, and site preparation techniques.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive at the interview on time to show respect and punctuality.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bulldozer Engineer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bulldozer Engineer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.