Feeling lost in a sea of interview questions? Landed that dream interview for Bulldozer/Loader/Compactor/Scraper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bulldozer/Loader/Compactor/Scraper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

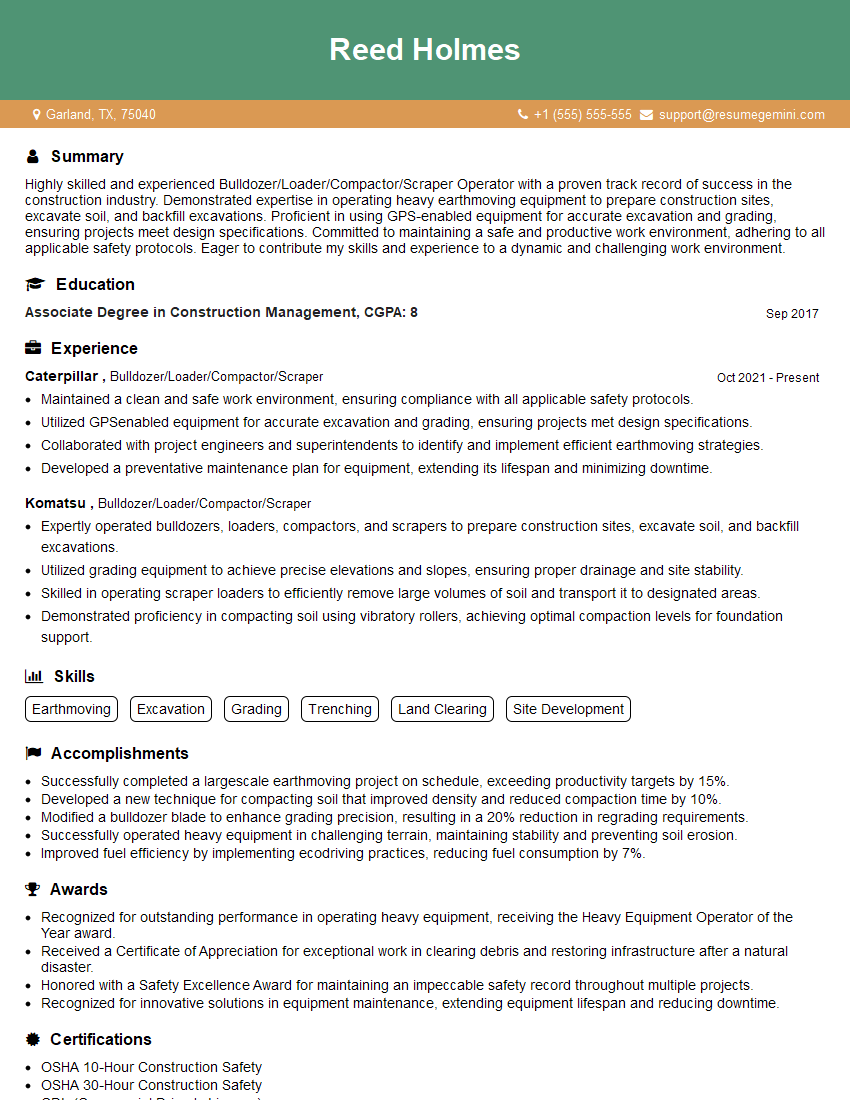

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bulldozer/Loader/Compactor/Scraper

1. What is the purpose of a hydraulic system on a Bulldozer/Loader/Compactor/Scraper?

The hydraulic system on a Bulldozer/Loader/Compactor/Scraper is responsible for powering the machine’s various attachments and components. It typically consists of a hydraulic pump, hydraulic lines, and hydraulic cylinders. The pump generates pressurized hydraulic fluid, which is then sent through the lines to the cylinders. The cylinders use the fluid to extend and retract, providing the power to operate the machine’s attachments and components.

2. What are the different types of hydraulic systems used on Bulldozers/Loaders/Compactors/Scrapers?

Open-center hydraulic systems

- In an open-center hydraulic system, the hydraulic pump continuously circulates fluid through the system, even when the controls are in neutral. This type of system is typically used on smaller machines, as it is less efficient than closed-center systems.

Closed-center hydraulic systems

- In a closed-center hydraulic system, the hydraulic pump only circulates fluid when the controls are activated. This type of system is more efficient than open-center systems, as it reduces energy loss.

3. What are the advantages and disadvantages of using a Bulldozer/Loader/Compactor/Scraper with a hydrostatic transmission?

Advantages

- Hydrostatic transmissions provide smooth and precise control of the machine’s speed and direction.

- They are also more efficient than mechanical transmissions, as they reduce energy loss.

Disadvantages

- Hydrostatic transmissions can be more expensive than mechanical transmissions.

- They can also be less durable, especially in harsh operating conditions.

4. What are the different types of blades that can be used on a Bulldozer?

- Straight blades are used for general-purpose dozing, such as pushing dirt and debris.

- Angling blades are used for grading and sloping, as they can be angled to the side.

- U-blades are used for moving large amounts of material, such as snow or sand.

- Tilt blades are used for fine grading and leveling, as they can be tilted to adjust the angle of the blade.

5. What are the different types of buckets that can be used on a Loader?

- General-purpose buckets are used for a variety of tasks, such as loading and unloading materials.

- Rock buckets are designed for handling heavy and abrasive materials, such as rocks and concrete.

- Coal buckets are designed for loading and transporting coal.

- Snow buckets are designed for removing snow and ice.

6. What are the different types of rollers that can be used on a Compactor?

- Smooth rollers are used for compacting smooth surfaces, such as asphalt and concrete.

- Padfoot rollers are used for compacting soils and other loose materials.

- Tamping rollers are used for compacting soils and other loose materials, and they can also be used to break up hard surfaces.

7. What are the different types of scrapers that can be used on a Scraper?

- Wheeled scrapers are used for moving large amounts of material over long distances.

- Track scrapers are used for moving large amounts of material over short distances.

- Elevating scrapers are used for loading and transporting material over short distances.

8. What are the safety precautions that should be taken when operating a Bulldozer/Loader/Compactor/Scraper?

- Always wear a seatbelt when operating the machine.

- Be aware of your surroundings and other workers in the area.

- Never operate the machine under the influence of drugs or alcohol.

- Inspect the machine before each use to ensure that it is in good working order.

- Follow all manufacturer’s instructions for operating the machine.

9. What are the different maintenance procedures that should be performed on a Bulldozer/Loader/Compactor/Scraper?

- Regularly check the machine’s fluid levels, including the engine oil, hydraulic fluid, and coolant.

- Inspect the machine’s filters, including the air filter, fuel filter, and hydraulic filter.

- Grease the machine’s moving parts, such as the pins and bushings.

- Check the machine’s tires for wear and tear.

- Follow all manufacturer’s instructions for maintaining the machine.

10. What are the troubleshooting procedures that can be used to diagnose and repair problems with a Bulldozer/Loader/Compactor/Scraper?

- If the machine is not starting, check the battery, starter, and fuel system.

- If the machine is not moving, check the transmission, hydraulic system, and tires.

- If the machine is not performing as expected, check the attachments, controls, and settings.

- Always refer to the manufacturer’s instructions for troubleshooting and repairing the machine.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bulldozer/Loader/Compactor/Scraper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bulldozer/Loader/Compactor/Scraper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bulldozer, Loader, Compactor, and Scraper operators play a crucial role in a variety of construction, mining, and excavation projects. These skilled professionals operate heavy machinery to perform essential tasks that support the efficient completion of these projects.

Bulldozer Operator

A Bulldozer Operator is responsible for:

- Operating bulldozers to clear land, level surfaces, and move dirt and other materials.

- Using various attachments, such as blades, rakes, and winches, to perform a range of tasks.

- Ensuring the safe and efficient operation of bulldozers to avoid accidents and damage to equipment and property.

Loader Operator

A Loader Operator is responsible for:

- Operating loaders to move materials, such as dirt, sand, and gravel, from one location to another.

- Using a variety of attachments, such as buckets, forks, and grapples, to perform different tasks.

- Ensuring the safe and efficient operation of loaders to avoid accidents and damage to equipment and property.

Compactor Operator

A Compactor Operator is responsible for:

- Operating compactors to compact soil, asphalt, and other materials to increase their density and strength.

- Using different types of compactors, such as vibratory rollers, pneumatic rollers, and static rollers, to suit the specific requirements of each project.

- Ensuring the safe and efficient operation of compactors to avoid accidents and damage to equipment and property.

Scraper Operator

A Scraper Operator is responsible for:

- Operating scrapers to excavate, transport, and spread soil and other materials over large areas.

- Using different types of scrapers, such as elevating scrapers, push-pull scrapers, and self-loading scrapers, to suit the specific requirements of each project.

- Ensuring the safe and efficient operation of scrapers to avoid accidents and damage to equipment and property.

Interview Tips

Preparing thoroughly for a Bulldozer/Loader/Compactor/Scraper Operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and the responsibilities of the role. You can find relevant information on the company’s website, LinkedIn page, and industry publications.

2. Practice Answering Common Interview Questions

There are certain interview questions that are commonly asked in Bulldozer/Loader/Compactor/Scraper Operator interviews. Practice answering these questions in advance so that you can deliver clear and concise responses during the actual interview. Some common questions include:

- Tell me about your experience operating heavy machinery.

- What are your strengths and weaknesses as a Bulldozer/Loader/Compactor/Scraper Operator?

- Why are you interested in working for our company?

- What are your salary expectations?

3. Highlight Your Skills and Experience

The interview is an opportunity for you to showcase your skills and experience as a Bulldozer/Loader/Compactor/Scraper Operator. Be prepared to discuss your proficiency in operating different types of heavy machinery, your ability to work independently and as part of a team, and your commitment to safety. Provide specific examples from your past work experience to demonstrate your qualifications.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you the opportunity to gather additional information that can help you make an informed decision about whether or not this is the right job for you. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the opportunities for professional development within the company?

- What is the company’s culture like?

5. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer. This is a simple but effective way to show your appreciation for their time and to reiterate your interest in the position. In your thank-you note, you can also highlight any additional qualifications or experience that you feel may have been overlooked during the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bulldozer/Loader/Compactor/Scraper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bulldozer/Loader/Compactor/Scraper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.