Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bulldozer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

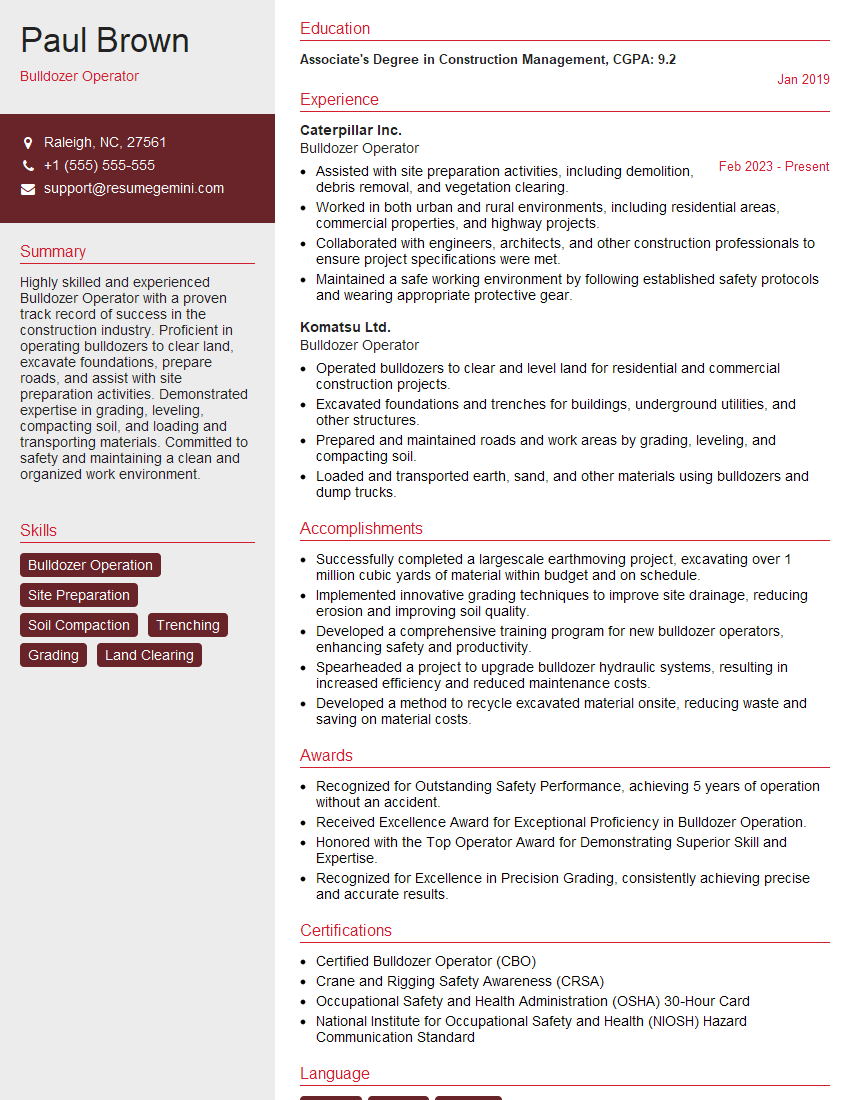

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bulldozer Operator

1. What are the different types of bulldozers and their uses?

Bulldozers are classified based on their blade types and undercarriage systems. Here are some common types and their uses:

- Angle Dozer: Used for backfilling, leveling, and shaping slopes, primarily in construction and mining.

- Straight Dozer: Designed for heavy-duty earthmoving tasks like land clearing, leveling, and cutting.

- Tilt Dozer: Allows for blade angle adjustments, making it suitable for grading, leveling, and finishing tasks.

- Track-type Bulldozer: Uses steel tracks for increased traction and stability, suitable for rough terrains and heavy-duty applications.

- Wheeled Bulldozer: Equipped with rubber tires, providing higher speed and maneuverability for lighter-duty tasks on paved or firm surfaces.

2. Describe the major components of a bulldozer and their functions?

Engine:

- Provides power to operate the hydraulic system and other components.

- Typically diesel-powered for durability and high torque.

Hydraulic System:

- Consists of pumps, valves, and cylinders.

- Transfers power from the engine to control blade movement, steering, and other functions.

Blade:

- The primary working component of a bulldozer.

- Used for pushing, scraping, and leveling soil or other materials.

Tracks or Wheels:

- Provide support and traction for the bulldozer.

- Tracks offer better stability and traction on uneven ground, while wheels provide higher speed and maneuverability.

Controls:

- Levers or joysticks used by the operator to control blade movement, steering, and other functions.

- Modern bulldozers often feature advanced controls with electronic systems for improved precision and efficiency.

3. What are the safety precautions that need to be taken when operating a bulldozer?

Operating a bulldozer requires strict adherence to safety guidelines. Some key precautions include:

- Always wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Conduct thorough pre-operation inspections to ensure the bulldozer is in good working order.

- Be aware of surroundings and potential hazards, such as overhead power lines or uneven terrain.

- Maintain a safe distance from other equipment and personnel.

- Avoid operating the bulldozer on slopes that exceed the manufacturer’s recommendations.

- Properly secure and transport loads to prevent accidents.

4. What is the proper technique for sloping and grading with a bulldozer?

Sloping and grading involve precise blade control to achieve desired angles and elevations:

- Sloping: Position the bulldozer perpendicular to the slope, use the blade to push material uphill or downhill, and maintain a constant angle.

- Grading: Set the blade at a specific angle, raise or lower it to adjust the height, and move the bulldozer forward or backward to level the ground.

- Proper blade placement, speed, and blade angle adjustments are crucial for achieving accurate slopes and grades.

5. How do you troubleshoot common bulldozer problems, such as hydraulic leaks or engine overheating?

Common bulldozer problems can be identified and resolved using troubleshooting techniques:

Hydraulic Leaks:

- Inspect hoses, fittings, and seals for leaks.

- Check hydraulic fluid levels and top up if necessary.

- Tighten loose connections or replace damaged components.

Engine Overheating:

- Inspect coolant levels and top up if low.

- Check the radiator for obstructions or debris.

- Ensure the fan belt is in good condition and properly adjusted.

6. What strategies do you use to improve efficiency and productivity while operating a bulldozer?

Maximizing productivity with a bulldozer requires efficient operating techniques:

- Plan the work area: Determine the most efficient path and blade movements before starting.

- Use the correct blade angle and speed: Adjust the blade angle and speed according to soil conditions and desired results.

- Minimize unnecessary movements: Avoid excessive back-and-forth motions and plan smooth transitions between tasks.

- Utilize technology: Use GPS systems or laser leveling devices to enhance accuracy and reduce rework.

7. Describe your experience in using attachments for bulldozers, such as rippers or winches?

Bulldozer attachments enhance versatility and functionality:

Rippers:

- Used for breaking up hard ground or removing roots and rocks.

- Choose the appropriate ripper tooth design for specific soil conditions.

Winches:

- Essential for pulling heavy objects or assisting other equipment.

- Ensure proper rigging and maintain safe tension on the winch cable.

8. How do you maintain a bulldozer to ensure optimal performance and longevity?

Regular maintenance is critical for bulldozer longevity:

- Daily Inspections: Check fluid levels, inspect tracks or wheels, and look for any loose or damaged components.

- Scheduled Maintenance: Follow manufacturer’s recommendations for oil changes, filter replacements, and other service intervals.

- Repairs: Promptly address any problems or failures to prevent further damage.

- Cleaning: Regularly clean the bulldozer to remove dirt, debris, and moisture.

9. What are the environmental considerations when operating a bulldozer?

Bulldozer operations must adhere to environmental regulations:

- Minimizing Soil Erosion: Use proper grading techniques to prevent excessive soil loss.

- Protecting Vegetation: Avoid unnecessary damage to plants and trees.

- Reducing Noise and Dust: Use mufflers and water suppression systems to mitigate noise and dust pollution.

- Revegetating Disturbed Areas: Replant vegetation after completing earthmoving activities.

10. Describe a challenging bulldozer operation you have encountered and how you successfully resolved it?

Every bulldozer operator faces unique challenges on the job:

- Describe a specific situation where you had to overcome obstacles, such as difficult terrain, tight spaces, or equipment malfunctions.

- Explain how you assessed the situation, developed a plan, and executed it successfully.

- Highlight your problem-solving skills, adaptability, and ability to work under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bulldozer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bulldozer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bulldozer operators are responsible for operating bulldozers to clear land, construct roads, and move materials. They must be able to operate the bulldozer safely and efficiently, and to work in a variety of conditions.

1. Operate bulldozers to clear land

Bulldozer operators use bulldozers to clear land for construction projects, farming, and other purposes. They must be able to operate the bulldozer safely and efficiently, and to work in a variety of conditions.

- Clear land for construction projects

- Clear land for farming

- Clear land for other purposes

2. Construct roads

Bulldozer operators use bulldozers to construct roads. They must be able to operate the bulldozer safely and efficiently, and to work in a variety of conditions.

- Construct roads

- Grade roads

- Compact roads

3. Move materials

Bulldozer operators use bulldozers to move materials. They must be able to operate the bulldozer safely and efficiently, and to work in a variety of conditions.

- Move materials

- Load materials

- Unload materials

4. Maintain bulldozers

Bulldozer operators are responsible for maintaining their bulldozers. They must be able to perform basic maintenance tasks, such as changing oil, filters, and spark plugs.

- Change oil

- Change filters

- Change spark plugs

Interview Tips

Preparing for a bulldozer operator interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, LinkedIn, and other online resources.

- Visit the company’s website

- Check out the company’s LinkedIn page

- Read articles about the company

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked during a bulldozer operator interview. It is important to practice answering these questions so that you can deliver clear and concise answers. Some common interview questions include:

- Tell me about your experience operating bulldozers.

- What are your strengths and weaknesses as a bulldozer operator?

- Why are you interested in this position?

- What are your salary expectations?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing anything too revealing or too casual.

- Wear clean, pressed clothes

- Wear shoes that are comfortable and polished

- Avoid wearing anything too revealing or too casual

4. Be confident and enthusiastic

Confidence and enthusiasm are essential for success in any interview. When you are confident, you will come across as more knowledgeable and experienced. When you are enthusiastic, you will show the interviewer that you are genuinely interested in the position.

- Make eye contact with the interviewer

- Speak clearly and confidently

- Smile and be enthusiastic

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bulldozer Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.