Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bullet Casting Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

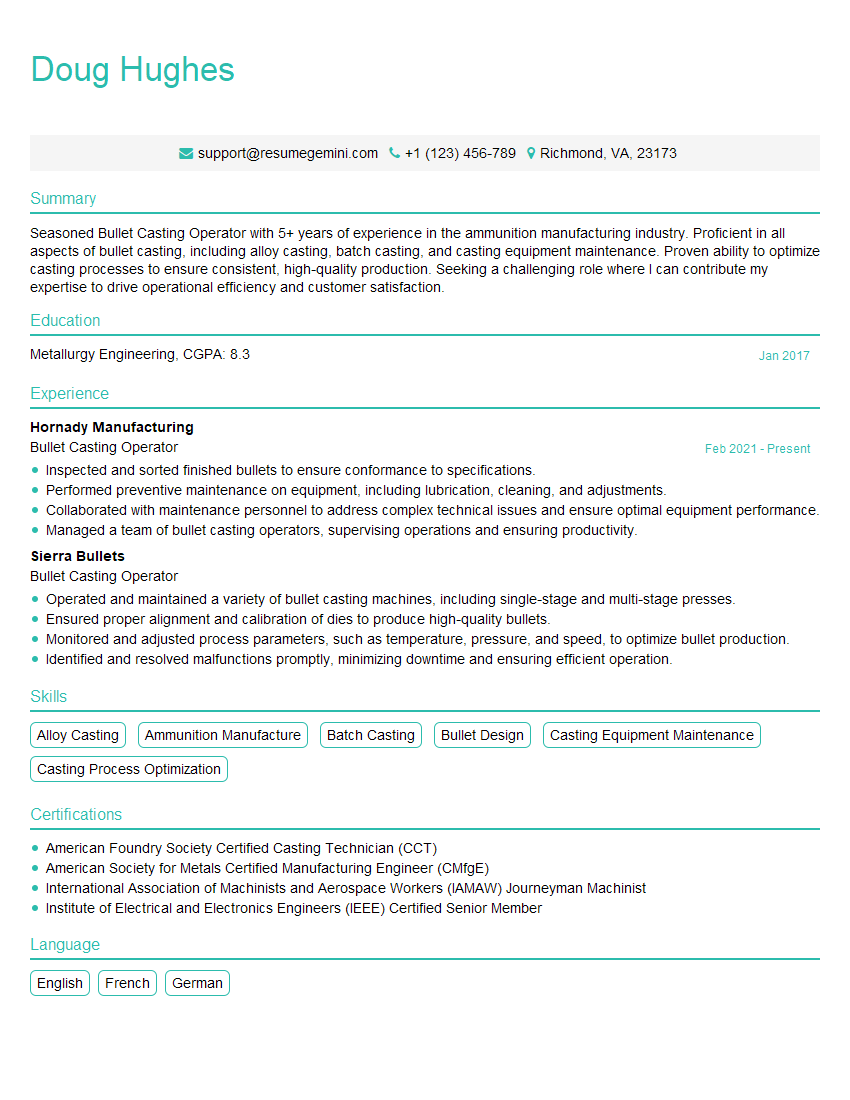

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bullet Casting Operator

1. Explain the process of centrifugal casting of bullets?

Centrifugal casting of bullets involves the following steps:

- Preparing the mold by cleaning and lubricating it.

- Melting the metal and pouring it into the mold.

- Rotating the mold at high speed to create centrifugal force.

- Cooling and solidifying the molten metal.

- Ejecting the cast bullet from the mold.

2. What are the different types of bullet casting molds?

Permanent molds

- Made of steel or iron that heated before use

- Produce high-quality bullets with consistent dimensions

Semi-permanent molds

- Made of aluminum or brass

- Less durable than permanent molds

- Can produce bullets with complex shapes

Disposable molds

- Made of plastic or paper

- Used for a single casting operation

- Convenient but produce bullets with less consistent dimensions

3. What are the factors that affect the quality of cast bullets?

The following factors affect the quality of cast bullets:

- Mold design and condition

- Metal composition and temperature

- Centrifugal force

- Cooling rate

- Lubrication

4. How do you troubleshoot common problems that occur during bullet casting?

Common problems during bullet casting include:

- Porosity: Caused by air bubbles trapped in the molten metal.

- Shrinkage: Caused by the metal cooling and shrinking too quickly.

- Cracking: Caused by uneven cooling or excessive stress on the bullet.

- Deformation: Caused by improper handling or storage.

Troubleshooting tips:

- Use a vacuum degassing system to remove air bubbles.

- Control the cooling rate by adjusting the mold temperature and rotation speed.

- Use a release agent to prevent the bullet from sticking to the mold.

- Handle and store bullets properly to avoid damage.

5. What are the safety precautions that must be followed when operating a bullet casting machine?

The following safety precautions must be followed:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Operate the machine in a well-ventilated area.

- Keep the machine clean and free of debris.

- Do not touch hot surfaces.

- Follow the manufacturer’s instructions for safe operation.

6. What is the difference between swaged and cast bullets?

Swaged bullets

- Formed by forcing lead wire through a die

- More consistent in weight and dimensions than cast bullets

- More expensive than cast bullets

Cast bullets

- Formed by pouring molten lead into a mold

- Less consistent in weight and dimensions than swaged bullets

- Less expensive than swaged bullets

7. What are the advantages and disadvantages of using cast bullets?

Advantages

- Less expensive than swaged bullets

- Can be customized to specific firearms

- Can be made from different alloys to achieve different performance characteristics

Disadvantages

- Less consistent in weight and dimensions than swaged bullets

- May require more frequent cleaning of firearms

- Can be more difficult to find in stores

8. What are the different types of bullet casting alloys?

The following are the most common bullet casting alloys:

- Pure lead: Soft and easy to cast, but not very hard or durable.

- Lead-tin alloy: Harder and more durable than pure lead, but still relatively soft.

- Lead-antimony alloy: Harder and more durable than lead-tin alloys, but can be more brittle.

- Lead-copper alloy: Harder and more durable than lead-antimony alloys, but can be more difficult to cast.

9. How do you calculate the weight of a cast bullet?

The weight of a cast bullet can be calculated using the following formula:

Weight = Volume X Density

Where:

- Weight is in grains

- Volume is in cubic inches

- Density is in grains per cubic inch

The density of lead is 0.410 grains per cubic inch.

10. What are the different types of bullet casting equipment?

The following are the most common types of bullet casting equipment:

- Melting pot: Used to melt the lead.

- Casting machine: Used to pour the molten lead into the mold.

- Mold: Used to shape the molten lead into a bullet.

- Lubricator: Used to apply a lubricant to the bullets.

- Sizer: Used to resize the bullets to the correct diameter.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bullet Casting Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bullet Casting Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bullet Casting Operators are responsible for operating and maintaining equipment used to cast bullets. They work in a manufacturing environment and are responsible for producing high-quality bullets to meet customer specifications.

1. Operating and Maintaining Equipment

Bullet Casting Operators are responsible for operating and maintaining a variety of equipment, including casting machines, molds, and furnaces. They must be able to troubleshoot problems and make necessary repairs to keep the equipment running smoothly.

- Operate casting machines to produce bullets according to specifications.

- Maintain and repair casting equipment, including molds and furnaces.

- Monitor equipment to ensure it is operating properly and make adjustments as needed.

2. Casting Bullets

Bullet Casting Operators are responsible for casting bullets to meet customer specifications. They must be able to control the temperature of the molten metal and the speed at which it is poured into the mold.

- Pour molten metal into molds to create bullets.

- Inspect bullets for defects and finish them as necessary.

- Package bullets for shipment.

3. Quality Control

Bullet Casting Operators are responsible for ensuring that the bullets they produce meet quality standards. They must be able to inspect bullets for defects and make necessary adjustments to the casting process.

- Inspect bullets for defects, such as cracks, voids, and imperfections.

- Make adjustments to the casting process to improve the quality of the bullets.

- Maintain records of quality control inspections.

4. Safety

Bullet Casting Operators work with molten metal and other hazardous materials. They must be able to follow safety procedures and wear appropriate personal protective equipment.

- Follow safety procedures to prevent accidents and injuries.

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a respirator.

- Maintain a clean and organized work area.

Interview Tips

Preparing for an interview can be a daunting task, but there are several things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Bullet Casting Operator position:

1. Research the Company and Position

Before you go to your interview, it is important to do your research on the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, Glassdoor, and other online resources.

- Visit the company website to learn about their history, mission, and products/services.

- Read reviews of the company on Glassdoor and other online resources.

- Research the specific job title to understand the responsibilities and qualifications required.

2. Practice Your Answers

Once you have a good understanding of the company and the position, you should start practicing your answers to common interview questions. This will help you to feel more confident and prepared during your interview.

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Practice your answers out loud to a friend or family member.

- Time yourself to make sure you are able to answer the questions within the time limit.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure your clothes are clean and pressed.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Avoid wearing strong perfumes or colognes.

4. Be on Time

Punctuality is important in any job interview. Make sure you arrive for your interview on time, or even a few minutes early. This shows the interviewer that you are respectful of their time.

- Plan your route to the interview location in advance.

- Give yourself plenty of time to get to the interview, even if you are running late.

- If you are running late, call the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

- Don’t try to be someone you’re not.

- Be honest and authentic.

- Let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bullet Casting Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.