Are you gearing up for an interview for a Bullet-Slug Casting Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bullet-Slug Casting Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

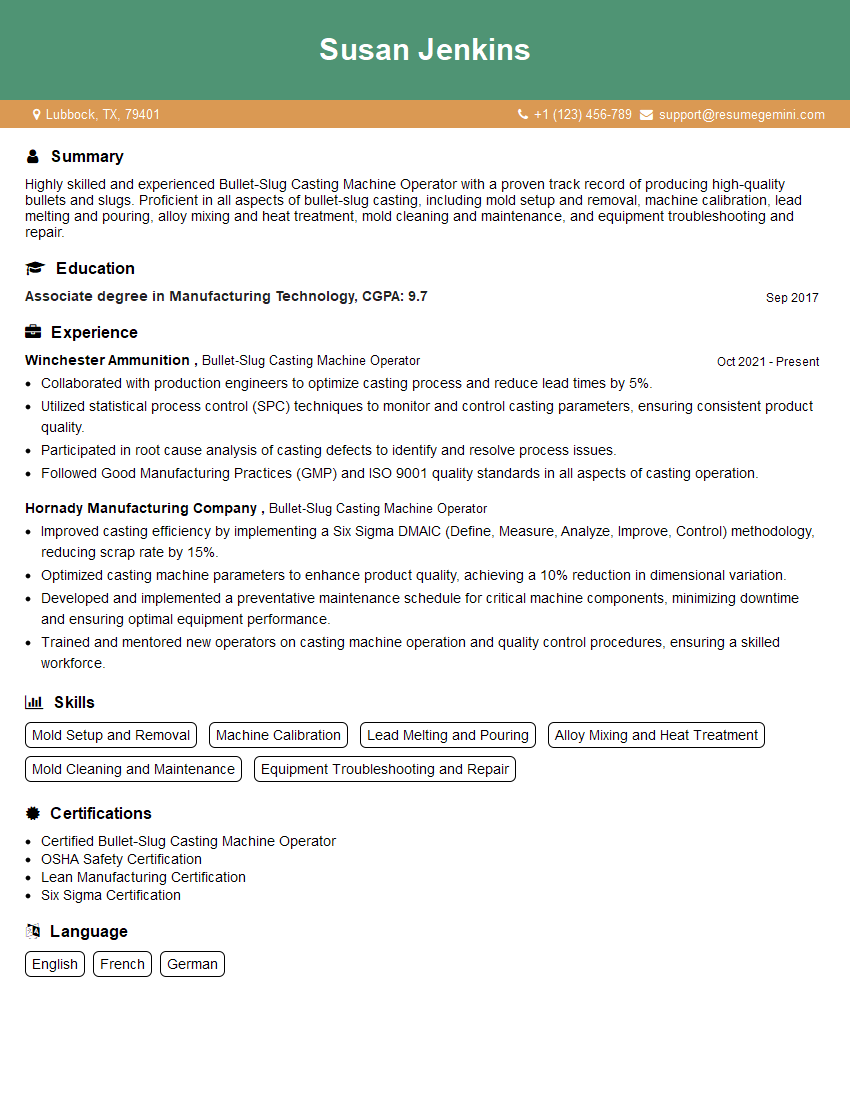

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bullet-Slug Casting Machine Operator

1. Explain the process of bullet-slug casting?

The process of bullet-slug casting involves several steps:

- Melting the lead: The lead is melted in a crucible using a furnace or other heating source.

- Preparing the mold: The mold is assembled and lubricated to ensure smooth casting.

- Casting: The molten lead is poured into the mold using a ladle or casting machine.

- Cooling: The mold is cooled to solidify the lead.

- Ejecting: The finished bullet-slug is ejected from the mold.

2. What are the different types of bullet-slug casting machines?

There are several types of bullet-slug casting machines, including:

- Hand-operated machines: These machines require manual operation to pour the molten lead and eject the finished bullet-slug.

- Semi-automatic machines: These machines automate the pouring process, while the ejection is still done manually.

- Fully-automatic machines: These machines automate both the pouring and ejection processes, offering increased efficiency.

3. What are the key factors to consider when selecting a bullet-slug casting machine?

When selecting a bullet-slug casting machine, it is important to consider the following factors:

- Production capacity: The machine’s ability to meet the desired production volume.

- Accuracy: The machine’s ability to produce consistent and accurate bullet-slugs.

- Efficiency: The machine’s ability to minimize downtime and maximize production.

- Cost: The initial investment and ongoing operating costs of the machine.

4. What are the safety precautions to observe when operating a bullet-slug casting machine?

Operating a bullet-slug casting machine requires strict adherence to safety precautions, including:

- Wearing appropriate protective gear: This includes heat-resistant gloves, safety glasses, and a mask.

- Ensuring proper ventilation: The work area should have adequate ventilation to remove harmful fumes.

- Handling molten lead with care: Molten lead can cause severe burns if mishandled.

- Following machine operating instructions: Always follow the manufacturer’s instructions for safe operation.

5. Explain the different types of defects that can occur in bullet-slug casting?

The following defects can occur in bullet-slug casting:

- Inclusions: Foreign materials trapped in the bullet-slug, which can weaken its integrity.

- Voids: Air pockets within the bullet-slug, which can affect its accuracy.

- Cracks: Fractures in the bullet-slug, which can result from improper cooling or casting techniques.

- Burrs: Rough edges or protrusions on the bullet-slug.

6. Describe the quality control procedures used in bullet-slug casting?

To ensure the quality of bullet-slugs, the following quality control procedures are typically implemented:

- Inspection: Bullet-slugs are visually inspected for defects, such as inclusions, voids, and cracks.

- Dimensional checks: Bullet-slugs are measured to ensure they meet specified dimensions.

- Weight checks: Bullet-slugs are weighed to ensure they meet the desired weight.

- Hardness testing: Bullet-slugs are tested for hardness to meet specified requirements.

7. Explain the maintenance procedures for a bullet-slug casting machine?

To keep the bullet-slug casting machine in good working condition, it is essential to follow proper maintenance procedures:

- Regular cleaning: The machine should be cleaned regularly to remove any lead residue or debris.

- Lubrication: Moving parts of the machine should be lubricated regularly to minimize wear and tear.

- Mold maintenance: The mold should be inspected regularly for any damage or wear, and replaced when necessary.

- Calibration: The machine should be calibrated periodically to ensure accurate pouring and ejection.

8. Describe the environmental concerns associated with bullet-slug casting?

Bullet-slug casting can have environmental implications, including:

- Lead emissions: Lead fumes and particles can be released into the air during the casting process.

- Water pollution: Lead can contaminate wastewater if not properly disposed of.

- Soil contamination: Lead can accumulate in soil if bullet-slugs are not properly disposed of.

9. Discuss the industry standards and regulations related to bullet-slug casting?

The bullet-slug casting industry is subject to various standards and regulations, including:

- OSHA regulations: These regulations set standards for workplace safety, including proper ventilation and handling of molten lead.

- EPA regulations: These regulations aim to minimize environmental impact by controlling lead emissions and disposal practices.

- Industry best practices: The industry has developed voluntary guidelines to promote responsible casting practices and minimize environmental risks.

10. What are the latest trends in bullet-slug casting technology?

The bullet-slug casting industry is constantly evolving with advancements in technology, including:

- Automated casting machines: New machines offer increased efficiency and precision in the casting process.

- Improved mold designs: Advanced mold designs enhance the accuracy and quality of bullet-slugs.

- Environmental mitigation systems: Technologies are being developed to minimize lead emissions and environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bullet-Slug Casting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bullet-Slug Casting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bullet-Slug Casting Machine Operators are responsible for the safe and efficient operation of bullet-slug casting machines, which are used to produce lead bullets or slugs for ammunition. Their primary duties include:

1. Machine Operation and Monitoring

Setting up and operating bullet-slug casting machines according to established procedures.

- Loading raw materials (lead, alloy metals, etc.) into the machine.

- Monitoring machine parameters (temperature, pressure, speed) to ensure optimal casting conditions.

- Troubleshooting and resolving machine malfunctions promptly.

2. Casting Process Control

Controlling the casting process to produce high-quality bullets or slugs.

- Adjusting casting variables (cooling rate, mold temperature, etc.) to achieve desired bullet or slug properties.

- Inspecting cast bullets or slugs for defects and non-conformance.

- Making necessary adjustments to the casting process based on inspection results.

3. Equipment and Tool Maintenance

Maintaining and cleaning bullet-slug casting machines and related equipment.

- Cleaning and lubricating machine components to prevent wear and tear.

- Inspecting and repairing or replacing worn or damaged parts.

- Keeping a clean and organized work area to ensure safety and efficiency.

4. Production Management

Meeting production targets and ensuring timely delivery of cast bullets or slugs.

- Estimating production capacity and materials consumption.

- Scheduling machine operation and coordinating with other departments.

- Maintaining inventory of raw materials and finished products.

Interview Tips

To prepare for an interview for a Bullet-Slug Casting Machine Operator position, candidates should consider the following tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the ammunition manufacturing industry by researching their history, products, and market trends.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay up-to-date on the latest advancements.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in operating and maintaining bullet-slug casting machines, as well as your knowledge of casting processes. If possible, quantify your accomplishments using specific metrics.

- Describe your experience in setting up and operating different types of bullet-slug casting machines.

- Discuss your ability to troubleshoot and resolve machine malfunctions.

- Provide examples of how you have optimized casting processes to improve product quality or efficiency.

3. Demonstrate Safety Awareness

Safety is paramount in this role. Highlight your commitment to following safety protocols and your knowledge of industry best practices to prevent accidents and injuries.

- Explain your understanding of the hazards associated with operating bullet-slug casting machines.

- Describe your experience with using personal protective equipment (PPE) and maintaining a safe work environment.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to bullet-slug casting machines and the casting process. This may include questions about:

- Machine operation and troubleshooting.

- Casting process parameters and their effects on bullet or slug properties.

- Quality control and inspection procedures.

5. Practice Your Communication Skills

Be able to clearly articulate your skills, experience, and qualifications. Practice answering common interview questions in a concise and engaging manner.

- Prepare an elevator pitch that summarizes your background and why you are the right candidate for the role.

- Practice mock interviews with a friend or family member to gain feedback on your presentation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bullet-Slug Casting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!