Are you gearing up for an interview for a Bullet Slugs Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bullet Slugs Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

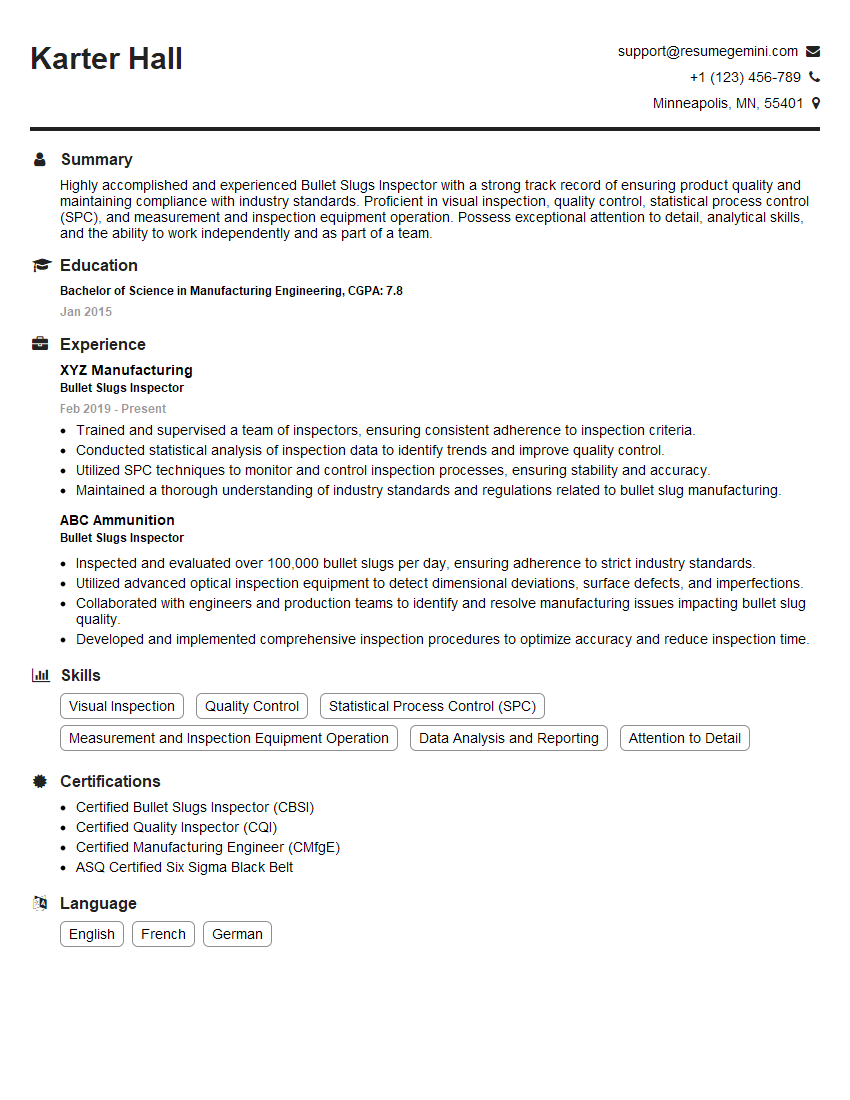

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bullet Slugs Inspector

1. Describe your understanding of a bullet slug?

In ballistics, a bullet slug is a solid, cylindro-conical projectile that is fired from a firearm. It is typically made of lead, copper, or a combination of both metals. Bullet slugs are designed to penetrate and cause damage to a target, and they can be used for hunting, self-defense, or target shooting.

2. How do you inspect bullet slugs for defects?

Visual Inspection

- Examine the bullet slug for any visible defects, such as cracks, dents, or corrosion.

- Check the bullet slug’s dimensions to ensure that they meet the manufacturer’s specifications.

Microscopic Inspection

- Use a microscope to examine the bullet slug’s surface for any microscopic defects, such as scratches or gouges.

- Check the bullet slug’s interior for any voids or inclusions.

X-ray Inspection

- Use an X-ray machine to examine the bullet slug for any internal defects, such as voids or cracks.

- X-ray inspection can also be used to determine the bullet slug’s composition.

3. What are the different types of defects that you can find in bullet slugs?

- Cracks

- Dents

- Corrosion

- Scratches

- Gouges

- Voids

- Inclusions

4. What are the causes of defects in bullet slugs?

- Improper manufacturing processes

- Damage during shipping or handling

- Corrosion

5. What are the consequences of using a bullet slug with a defect?

- The bullet slug may not perform as intended.

- The bullet slug may cause damage to the firearm.

- The bullet slug may cause injury to the shooter or to others.

6. What are the steps involved in the inspection process for bullet slugs?

- Visual inspection

- Microscopic inspection

- X-ray inspection

- Dimensional inspection

- Composition analysis

7. What are the quality standards for bullet slugs?

- The bullet slug must be free of any defects.

- The bullet slug must meet the manufacturer’s specifications for dimensions and weight.

- The bullet slug must be made of a material that is suitable for the intended use.

8. What are the tools and equipment that you use to inspect bullet slugs?

- Microscope

- X-ray machine

- Dimensional measuring equipment

- Composition analyzer

9. What are the safety precautions that you take when inspecting bullet slugs?

- Always wear safety glasses and gloves when handling bullet slugs.

- Never point a bullet slug at anyone.

- Never load a bullet slug into a firearm until you are ready to fire.

- Store bullet slugs in a safe and secure location.

10. What are the challenges of inspecting bullet slugs?

- Bullet slugs can be small and difficult to handle.

- Bullet slugs can be made of a variety of materials, which can make it difficult to inspect them using a single method.

- Bullet slugs can be damaged easily, so it is important to handle them with care.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bullet Slugs Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bullet Slugs Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Bullet Slugs Inspector is a crucial role in ensuring the quality and safety of firearm ammunition. Their key responsibilities involve rigorous inspections and testing to verify the dimensional accuracy, surface quality, weight, and other characteristics of bullet slugs.

1. Dimensional Inspection

Consistently measures and verifies the dimensions of bullet slugs against established specifications, ensuring adherence to prescribed tolerances.

- Utilizes precision measuring equipment, such as micrometers and calipers, to measure diameters, lengths, and other critical dimensions.

- Identifies and segregates slugs that deviate from specifications, maintaining a clear record of nonconformances.

2. Surface Inspection

Thoroughly examines the surface of bullet slugs for any imperfections or defects that could compromise performance or safety.

- Visually inspects slugs under controlled lighting conditions, identifying cracks, dents, or other surface irregularities.

- Employs non-destructive testing methods, such as magnetic particle inspection or eddy current testing, to detect hidden defects.

3. Weight Verification

Precisely measures the weight of bullet slugs and compares it to specified tolerances, ensuring consistent performance.

- Utilizes calibrated scales and precision weighing techniques to determine the exact weight of each slug.

- Rejects slugs that fall outside the acceptable weight range, preventing potential safety hazards or performance issues.

4. Documentation and Reporting

Maintains accurate and comprehensive records of all inspections, including measurements, test results, and nonconformances.

- Completes detailed inspection reports and submits them to designated authorities for review and analysis.

- Communicates findings and recommendations to ensure continuous improvement in the production process.

Interview Tips

To ace the interview for the role of Bullet Slugs Inspector, it is essential to prepare thoroughly and demonstrate your skills and knowledge.

1. Research the Company and Industry

Familiarize yourself with the organization’s profile, products, and industry trends. Understanding their values and mission will help you connect your experiences and aspirations to the job.

2. Practice Describing Your Skills

Highlight your proficiency in dimensional inspection, surface inspection, and weight verification techniques. Use specific examples to showcase your expertise in handling precision measuring equipment and non-destructive testing methods.

3. Emphasize Attention to Detail

Emphasize your keen eye for detail and your ability to detect even minor imperfections or deviations from specifications. Showcase examples of how your meticulousness has contributed to quality control and safety.

4. Prepare for Technical Questions

Review basic principles of dimensional measurement, material properties, and safety protocols. Anticipate questions related to your understanding of the manufacturing process and potential quality issues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bullet Slugs Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!