Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Burling and Joining Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Burling and Joining Supervisor so you can tailor your answers to impress potential employers.

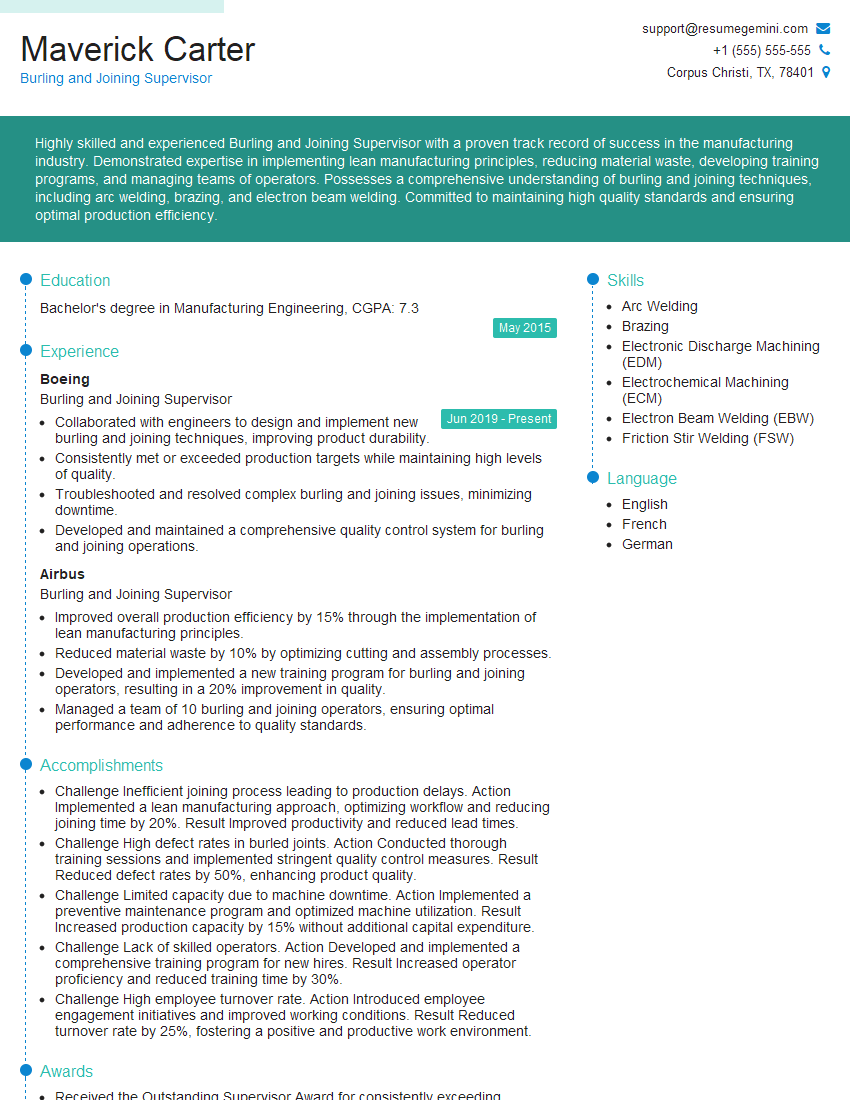

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Burling and Joining Supervisor

1. Explain the process of burling and joining in garment manufacturing?

Burling and joining are essential processes in garment manufacturing that ensure the fabric is free of defects and the seams are smooth and durable.

- Burling: This process involves meticulously inspecting the fabric for any imperfections such as slubs, knots, or snags. It is typically done by hand using a needle or tweezers to remove any protruding threads or yarn ends.

- Joining: This step involves sewing the different fabric pieces together to create the garment. It can be done manually using a sewing machine or by using automated equipment. The aim is to create strong and consistent seams that meet the garment’s design specifications.

2. What are the different types of burling and joining methods used in the industry?

- Hand burling: This is the traditional method of burling, where a skilled worker manually inspects and removes fabric defects using a needle or tweezers.

- Automated burling: This method utilizes specialized machines equipped with sensors to detect and remove fabric imperfections.

- Manual joining: This method involves using a sewing machine to sew the fabric pieces together by hand.

- Automated joining: This method employs automated machines to sew the seams, resulting in increased efficiency and consistency.

3. What are the critical quality control parameters for burling and joining?

- Defect removal: Ensuring that all fabric defects are identified and removed during burling.

- Seam strength: Verifying that the seams are securely sewn and can withstand the stresses of garment use.

- Seam appearance: Inspecting seams for evenness, smoothness, and adherence to design specifications.

- Fabric damage prevention: Ensuring that the burling and joining processes do not damage the fabric.

4. How do you ensure the quality of burling and joining operations?

- Training and supervision: Providing comprehensive training to operators and closely supervising their work.

- Regular inspections: Conducting regular quality checks on the fabric and seams to identify any potential issues.

- Use of quality materials: Utilizing high-quality thread and needles to ensure durability and prevent seam failures.

- Maintenance of equipment: Regularly servicing and calibrating burling and joining machines to ensure optimal performance.

5. What are the common challenges faced during burling and joining, and how do you overcome them?

- Fabric defects: Dealing with various fabric defects requires skilled burling operators to effectively remove them without damaging the fabric.

- Seam puckering: Overcoming seam puckering involves adjusting machine settings and using the correct sewing techniques.

- Thread breakage: Preventing thread breakage requires using high-quality thread and regularly inspecting and replacing needles.

- Operator fatigue: Addressing operator fatigue involves implementing ergonomic workstations and providing regular breaks.

6. How do you manage a team of burling and joining operators?

Effective Communication

- Establish clear communication channels.

- Provide regular updates on production goals and quality standards.

Motivation and Training

- Recognize and reward employees for their contributions.

- Provide ongoing training to enhance their skills and knowledge.

Performance Monitoring

- Track individual and team performance metrics.

- Identify areas for improvement and provide targeted feedback.

7. What is your approach to continuous improvement in burling and joining processes?

- Process analysis: Regularly reviewing and analyzing current processes to identify potential areas for improvement.

- Technology adoption: Exploring and implementing new technologies to enhance efficiency and quality.

- Operator involvement: Engaging operators in the improvement process to gather their insights and suggestions.

- Performance monitoring: Tracking key performance indicators to measure the effectiveness of improvements.

8. How do you stay updated with the latest advancements in burling and joining techniques?

- Industry events: Attending conferences, workshops, and trade shows to learn about new technologies and best practices.

- Research and development: Reading industry publications and conducting research to stay informed about advancements.

- Collaboration with suppliers: Partnering with equipment manufacturers and material suppliers to gain insights into emerging solutions.

9. What are your strengths and weaknesses as a Burling and Joining Supervisor?

Strengths

- Proficient in both manual and automated burling and joining techniques.

- Excellent understanding of fabric properties and defect identification.

- Proven ability to train, motivate, and manage a team of operators.

Weaknesses

- Limited experience with certain specialized burling and joining equipment.

- Working under tight deadlines can be challenging at times.

10. Why are you interested in this role, and what makes you the ideal candidate?

I am eager to contribute my expertise and leadership to this role as a Burling and Joining Supervisor. With my proven track record in the garment manufacturing industry, I am confident in my ability to optimize processes, ensure product quality, and drive continuous improvement.

- My technical skills and industry knowledge align perfectly with the requirements of this role.

- I am passionate about quality and have a keen eye for detail, ensuring the production of high-quality garments.

- My commitment to continuous learning and innovation will enable me to stay abreast of industry advancements and implement best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Burling and Joining Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Burling and Joining Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Burling and Joining Supervisor plays a crucial role in overseeing and coordinating the processes of burling and joining in a production environment. Their primary responsibilities include:

1. Plan and Manage Burling and Joining Operations

Plan and schedule burling and joining activities to ensure timely completion and adherence to quality standards.

- Assign tasks and monitor progress, providing guidance and support to team members.

- Establish and implement quality control measures to ensure products meet specifications.

2. Supervise Burling and Joining Teams

Lead and motivate burling and joining teams, fostering a positive and productive work environment.

- Provide training and development to team members to enhance their skills and knowledge.

- Address performance issues and provide constructive feedback to improve outcomes.

3. Monitor and Evaluate Production

Continuously monitor production processes to identify areas for improvement and optimization.

- Analyze production data to identify trends and potential bottlenecks.

- Implement process improvements to increase efficiency and reduce waste.

4. Collaborate with Other Departments

Collaborate with other departments, such as Engineering and Quality Control, to ensure seamless operations.

- Provide input on product design and specifications to improve burling and joining processes.

- Work with Quality Control to ensure adherence to quality standards and resolve any issues.

Interview Tips

Preparing for a Burling and Joining Supervisor interview requires a comprehensive understanding of the role and the ability to convey your relevant skills and experience effectively. Here are some tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company, its industry, and the specific role you are applying for. This will demonstrate your interest and knowledge, and it will help you answer questions intelligently.

- Visit the company website to learn about their mission, values, and products/services.

- Read industry news and publications to stay up-to-date on trends and best practices.

2. Practice Answering Common Questions

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview.

- Tell me about your experience in burling and joining.

- How do you manage and motivate a team?

- What is your approach to quality control?

3. Highlight Relevant Skills and Experience

During the interview, be sure to highlight your relevant skills and experience that align with the job requirements. Use specific examples to demonstrate your abilities.

- Emphasize your technical expertise in burling and joining techniques.

- Share examples of how you have successfully managed and motivated teams in the past.

- Provide evidence of your commitment to quality control and your ability to identify and resolve issues.

4. Show Enthusiasm and Confidence

Your enthusiasm and confidence can make a significant impact on the interviewer. Convey your passion for the role and your belief in your ability to succeed.

- Maintain eye contact, speak clearly, and project a positive attitude.

- Be prepared to share why you are interested in the role and what you bring to the table.

- Ask thoughtful questions at the end of the interview to show your engagement and interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Burling and Joining Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!