Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Butadiene Convertor Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

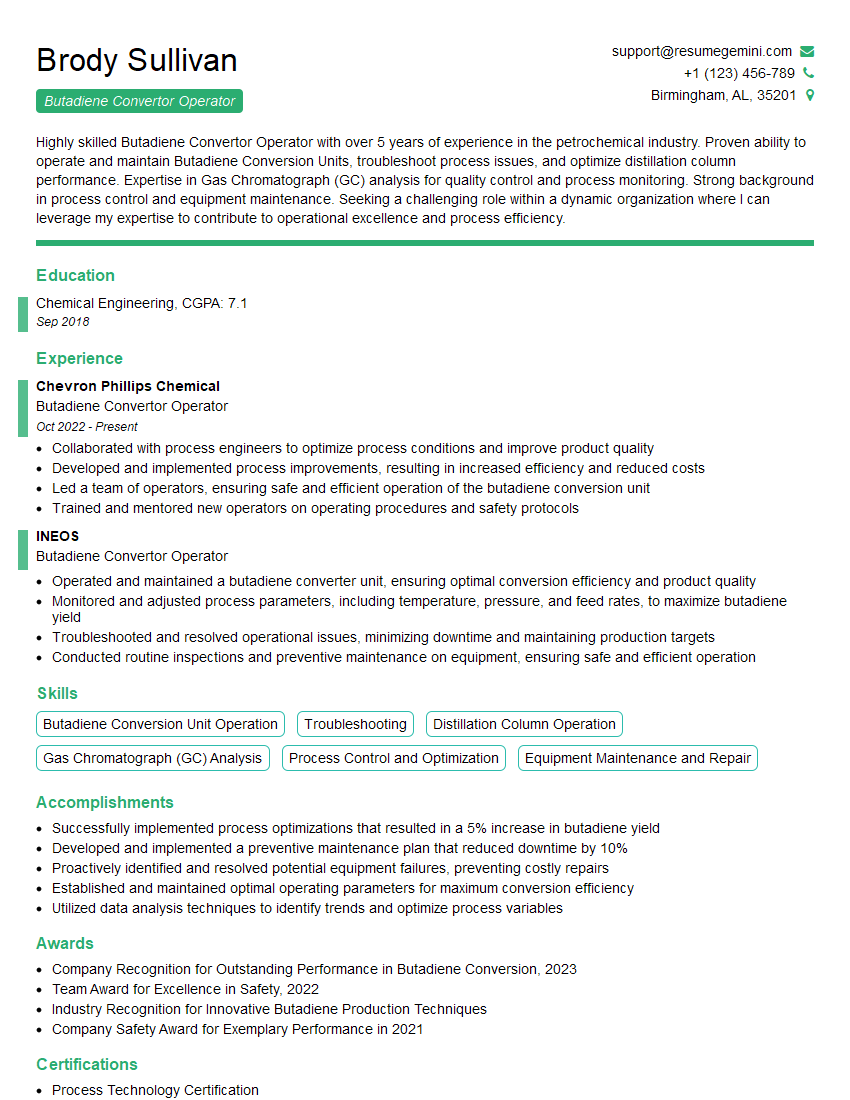

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Butadiene Convertor Operator

1. Explain the principles of butadiene conversion process.

The butadiene conversion process involves converting butane into butadiene, a key chemical used in the production of synthetic rubber and plastics. The process typically involves the following steps:

- Dehydrogenation: Butane is dehydrogenated to form butenes, which are a mixture of 1-butene and 2-butene.

- Isomerization: The butenes are isomerized to form isobutene, which is the preferred feedstock for butadiene production.

- Dimerization: Isobutene is dimerized to form isobutylene, which is a four-carbon molecule.

- Cracking: Isobutylene is cracked to form butadiene and other byproducts.

2. Describe the different types of butadiene converters and their advantages and disadvantages.

Fixed-bed reactors

- Advantages: Simple design, low capital cost, high conversion rates.

- Disadvantages: Prone to catalyst deactivation, requires frequent maintenance.

Fluidized-bed reactors

- Advantages: Good mixing, high heat transfer rates, reduced catalyst deactivation.

- Disadvantages: Higher capital cost, more complex design.

Circulating fluidized-bed reactors

- Advantages: High conversion rates, good mixing, reduced catalyst deactivation.

- Disadvantages: Higher capital cost, more complex design than fluidized-bed reactors.

3. What are the key operating parameters that affect the efficiency of a butadiene converter?

The key operating parameters that affect the efficiency of a butadiene converter include:

- Temperature: The temperature of the reactor affects the rate of the chemical reactions involved in the conversion process. Higher temperatures generally favor the conversion of butane to butadiene, but can also lead to the formation of unwanted byproducts.

- Pressure: The pressure of the reactor affects the equilibrium of the chemical reactions involved in the conversion process. Higher pressures favor the formation of butadiene, but can also increase the cost of the process.

- Catalyst: The catalyst used in the converter plays a crucial role in the efficiency of the process. The choice of catalyst depends on the specific process conditions, and the desired product yield and selectivity.

- Feedstock: The composition of the feedstock can also affect the efficiency of the converter. The presence of impurities or other components in the feedstock can interfere with the chemical reactions involved in the conversion process.

4. How do you troubleshoot common problems that occur in butadiene converters?

Common problems that occur in butadiene converters include:

- Catalyst deactivation: Catalyst deactivation can occur due to a variety of factors, such as poisoning by impurities in the feedstock, or thermal deactivation. To troubleshoot catalyst deactivation, the catalyst should be inspected and tested to determine the cause of the deactivation.

- Reactor fouling: Reactor fouling can occur due to the deposition of coke or other materials on the reactor walls. To troubleshoot reactor fouling, the reactor should be inspected and cleaned to remove the deposits.

- Equipment failure: Equipment failure can occur due to a variety of factors, such as mechanical failure or electrical failure. To troubleshoot equipment failure, the equipment should be inspected and repaired or replaced as necessary.

5. What are the safety precautions that must be taken when operating a butadiene converter?

Butadiene is a highly flammable gas, and proper safety precautions must be taken when operating a butadiene converter. These precautions include:

- Proper ventilation: The converter area should be well-ventilated to prevent the accumulation of butadiene gas.

- Leak detection: The converter should be equipped with leak detection systems to detect and prevent the release of butadiene gas.

- Fire protection: The converter area should be equipped with fire protection systems, such as sprinklers and fire extinguishers.

- Personal protective equipment: Operators should wear appropriate personal protective equipment, such as respirators and gloves, when working with butadiene.

6. What are the environmental regulations that apply to butadiene converters?

Butadiene converters are subject to a variety of environmental regulations, including:

- Clean Air Act: The Clean Air Act regulates the emission of air pollutants, including butadiene. Butadiene converters must comply with the emission limits set by the Clean Air Act.

- Clean Water Act: The Clean Water Act regulates the discharge of wastewater, including wastewater from butadiene converters. Butadiene converters must comply with the effluent limits set by the Clean Water Act.

7. What are the industry best practices for operating a butadiene converter?

The industry best practices for operating a butadiene converter include:

- Proper maintenance: The converter should be properly maintained to prevent equipment failure and to ensure optimal performance.

- Operator training: Operators should be trained on the safe and efficient operation of the converter.

- Process optimization: The converter should be operated at the optimal conditions to maximize yield and selectivity.

- Environmental compliance: The converter should be operated in compliance with all applicable environmental regulations.

8. What are the emerging technologies for butadiene conversion?

Emerging technologies for butadiene conversion include:

- Membrane reactors: Membrane reactors use a selective membrane to separate the products of the conversion process. This can improve the yield and selectivity of the process.

- Catalytic distillation: Catalytic distillation combines the processes of distillation and catalysis. This can improve the energy efficiency of the conversion process.

- Reactive extraction: Reactive extraction combines the processes of extraction and reaction. This can improve the yield and selectivity of the conversion process.

9. What is your experience with butadiene conversion processes?

In my previous role as a Butadiene Convertor Operator at [Company Name], I was responsible for the operation and maintenance of a butadiene converter. My responsibilities included:

- Monitoring the converter operating parameters

- Troubleshooting and resolving process problems

- Performing routine maintenance and repairs

- Ensuring compliance with all safety and environmental regulations

10. What are your career goals?

My career goal is to become a Butadiene Convertor Supervisor. I am confident that my experience and skills make me a strong candidate for this position. I am eager to learn more about the butadiene conversion process and to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Butadiene Convertor Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Butadiene Convertor Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Butadiene Convertor Operator is responsible for the safe and efficient operation of a butadiene converter unit. The primary role of this position is to ensure the production of butadiene, a key chemical used in the manufacturing of synthetic rubber and plastics, by monitoring and adjusting process variables, troubleshooting any issues, and maintaining the equipment.

1. Monitor and Control Process Variables

The operator monitors and adjusts process variables such as temperature, pressure, and flow rates to maintain optimal operating conditions for the converter. This involves using control panels, computer systems, and other instrumentation to ensure that the process is running smoothly and efficiently.

- Monitor temperature, pressure, and flow rates of reactants and products.

- Adjust valves and other controls to maintain desired process conditions.

- Analyze data and make adjustments to optimize process efficiency.

2. Troubleshoot and Resolve Issues

The operator troubleshoots and resolves any issues that arise during the conversion process. This may involve identifying the source of the problem, taking corrective actions, and monitoring the situation to ensure that the issue is resolved effectively.

- Identify and diagnose equipment malfunctions or process upsets.

- Take corrective actions to resolve issues and restore normal operation.

- Monitor the situation to ensure the issue is resolved and does not reoccur.

3. Maintain Equipment

The operator performs routine maintenance and repairs on the converter unit and associated equipment. This may involve cleaning, lubricating, inspecting, and replacing parts as needed to ensure the equipment is in good working order and meets safety standards.

- Clean and lubricate equipment to prevent malfunctions.

- Inspect equipment for wear and tear and replace parts as necessary.

- Follow safety protocols and adhere to maintenance schedules.

4. Adhere to Safety Regulations and Procedures

The operator strictly adheres to all safety regulations and procedures to ensure a safe work environment. This involves following proper lockout/tagout procedures, wearing appropriate personal protective equipment (PPE), and being aware of potential hazards associated with the process.

- Follow lockout/tagout procedures to prevent accidents.

- Wear appropriate PPE, such as gloves, safety glasses, and hearing protection.

- Be aware of potential hazards and take appropriate precautions.

Interview Tips

To ace your interview for a Butadiene Convertor Operator position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the butadiene industry. Research the company’s website, industry news, and recent developments to show that you’re informed and passionate about the field.

- Read the company’s website and annual reports.

- Stay up-to-date on industry news and trends.

- Network with professionals in the industry.

2. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience in operating butadiene converter units. Describe your responsibilities, accomplishments, and any specific knowledge or expertise you have that is relevant to the role.

- Quantify your accomplishments with specific metrics and results.

- Use industry-specific terminology and concepts to demonstrate your expertise.

- Be prepared to discuss your experience in troubleshooting and resolving process issues.

3. Showcase Your Safety Mindset

Safety is paramount in this role. Highlight your commitment to safety by emphasizing your knowledge of safety regulations and procedures. Describe your experience in following lockout/tagout procedures and wearing appropriate PPE.

- Explain your understanding of the importance of safety in the chemical industry.

- Discuss your experience with safety protocols and risk assessments.

- Mention any safety certifications or training you have received.

4. Practice Your Communication Skills

As a Butadiene Convertor Operator, you will need to be able to communicate effectively with other operators, supervisors, and maintenance personnel. Practice your communication skills by preparing clear and concise answers to common interview questions.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice speaking confidently and articulately.

- Be prepared to answer questions about your availability and willingness to work shifts.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Butadiene Convertor Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.