Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Buttermilk Drier Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

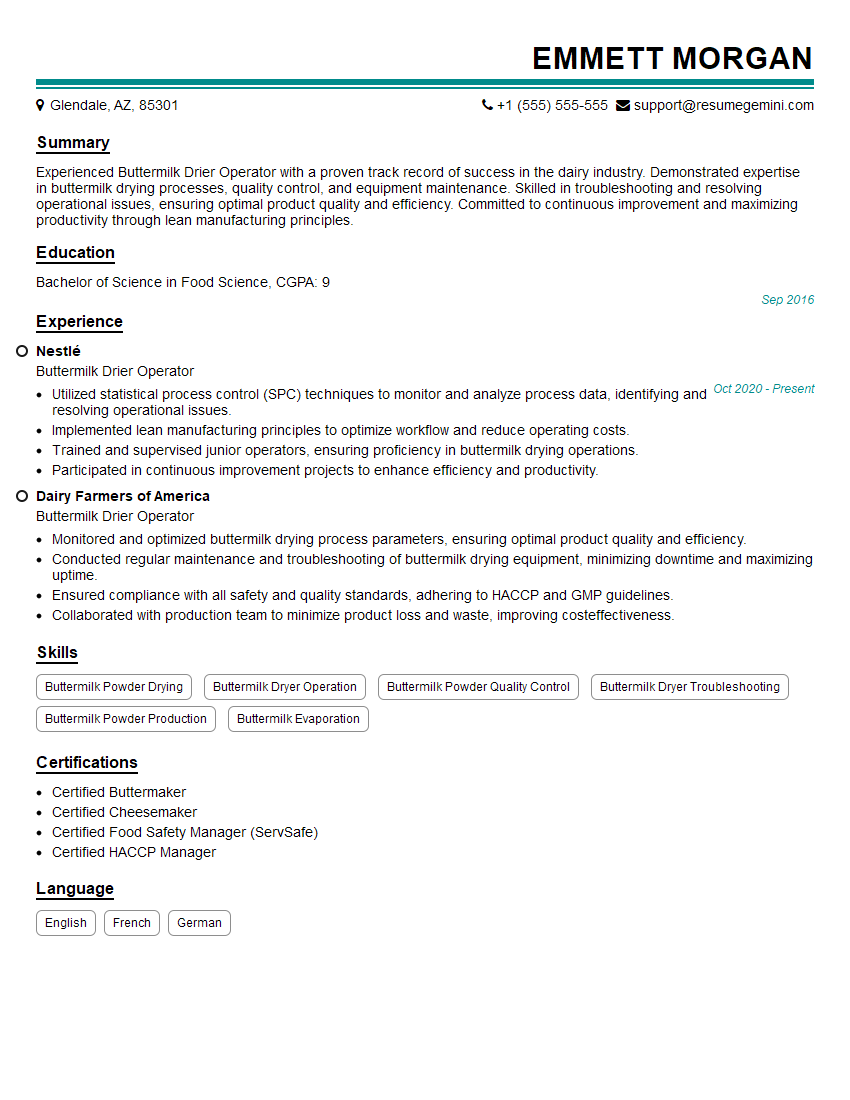

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Buttermilk Drier Operator

1. Explain the process of buttermilk drying.

- Buttermilk is first preheated to a temperature of approximately 50°C (122°F) to denature the whey proteins.

- The preheated buttermilk is then atomized into a fine mist using a spray dryer.

- The mist is then passed through a heated air stream, which causes the water to evaporate and the buttermilk solids to dry.

- The dried buttermilk powder is then collected and packaged.

2. What are the critical control points in the buttermilk drying process?

Temperature

- The preheat temperature, the temperature of the air stream used for drying, and the temperature of the dried buttermilk powder are all critical control points.

- If the temperature is too low, the buttermilk will not dry properly and may spoil.

- If the temperature is too high, the buttermilk powder may scorch.

Moisture content

- The moisture content of the dried buttermilk powder is also a critical control point.

- If the moisture content is too high, the buttermilk powder may be susceptible to spoilage.

- If the moisture content is too low, the buttermilk powder may be difficult to rehydrate.

pH

- The pH of the buttermilk powder is also a critical control point.

- If the pH is too low, the buttermilk powder may be acidic and have a sour taste.

- If the pH is too high, the buttermilk powder may be alkaline and have a bitter taste.

3. What are the common problems that can occur during the buttermilk drying process?

- Scorching

- Caking

- Lumping

- Spoilage

4. How can these problems be prevented?

- Scorching can be prevented by controlling the temperature of the air stream used for drying.

- Caking can be prevented by adding an anti-caking agent to the buttermilk before drying.

- Lumping can be prevented by using a spray dryer with a fine atomizer.

- Spoilage can be prevented by controlling the moisture content and pH of the dried buttermilk powder.

5. What is the role of the buttermilk drier operator?

- The buttermilk drier operator is responsible for monitoring and controlling the buttermilk drying process.

- This includes monitoring the temperature, moisture content, and pH of the buttermilk powder.

- The buttermilk drier operator also makes adjustments to the drying process as needed to ensure that the buttermilk powder meets specifications.

6. What are the qualifications for a buttermilk drier operator?

- A high school diploma or equivalent

- Experience in the food industry

- Knowledge of the buttermilk drying process

- Ability to monitor and control equipment

- Ability to work in a team environment

7. What are the benefits of working as a buttermilk drier operator?

- Competitive salary and benefits

- A stable work environment

- Opportunities for advancement

8. What is the future outlook for buttermilk drier operators?

- The outlook for buttermilk drier operators is expected to be good over the next few years.

- This is due to the increasing demand for buttermilk powder in the food industry.

9. What are your career goals?

- I would like to become a supervisor in the food industry.

- I am also interested in learning more about the buttermilk drying process and developing new ways to improve the efficiency of the process.

10. Do you have any questions for me?

- I would like to know more about the company’s safety procedures.

- I am also interested in learning more about the company’s quality control standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Buttermilk Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Buttermilk Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Buttermilk Drier Operator plays a crucial role in the dairy industry, operating and maintaining complex buttermilk drying equipment. Their responsibilities encompass all aspects of buttermilk drying operations, ensuring efficient production and adherence to quality standards.

1. Equipment Operation

Operate and monitor buttermilk drying equipment, including spray dryers, cyclones, and bagging machines.

- Monitor drying conditions (temperature, pressure, flow rates) to optimize drying efficiency.

- Control buttermilk feed rates and ensure uniform buttermilk distribution in the drying chamber.

- Troubleshoot and resolve operational issues promptly to minimize downtime.

2. Quality Assurance

Monitor buttermilk quality throughout the drying process, ensuring adherence to specifications.

- Conduct regular moisture content tests on dried buttermilk.

- Monitor particle size and density to meet customer requirements.

- Inspect dried buttermilk for any abnormalities or defects.

3. Production Planning and Scheduling

Plan and schedule buttermilk drying operations to meet production targets.

- Estimate buttermilk drying times and plan drying schedules.

- Coordinate with other departments (receiving, packaging) to ensure smooth production flow.

- Monitor inventory levels of raw buttermilk and dried buttermilk.

4. Maintenance and Sanitation

Perform routine maintenance and sanitation of buttermilk drying equipment.

- Clean and inspect equipment on a regular basis.

- Lubricate and adjust equipment to ensure optimal performance.

- Follow GMP (Good Manufacturing Practices) and sanitation protocols to maintain a hygienic environment.

Interview Tips

Preparing thoroughly for your Buttermilk Drier Operator interview is essential to showcase your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Role

Learn about the company’s dairy operations, buttermilk drying processes, and industry trends. Familiarize yourself with the specific responsibilities of the Buttermilk Drier Operator role.

2. Highlight Your Technical Skills

Emphasize your knowledge of buttermilk drying equipment, quality control procedures, and maintenance practices. Provide examples of your successful operation and troubleshooting of buttermilk driers.

3. Showcase Your Quality-Focused Mindset

Demonstrate your commitment to maintaining high-quality dried buttermilk products. Explain your understanding of GMP regulations and your ability to monitor and control quality parameters during the drying process.

4. Prepare for Troubleshooting Questions

Anticipate questions about your problem-solving abilities and how you handle operational issues. Share examples from your previous experience where you identified and resolved problems with buttermilk drying equipment.

5. Emphasize Teamwork and Communication

Highlight your ability to work effectively in a team environment and communicate clearly with other departments. Explain how you coordinate with colleagues to ensure smooth production operations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Buttermilk Drier Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!