Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Button Attaching Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Button Attaching Machine Operator so you can tailor your answers to impress potential employers.

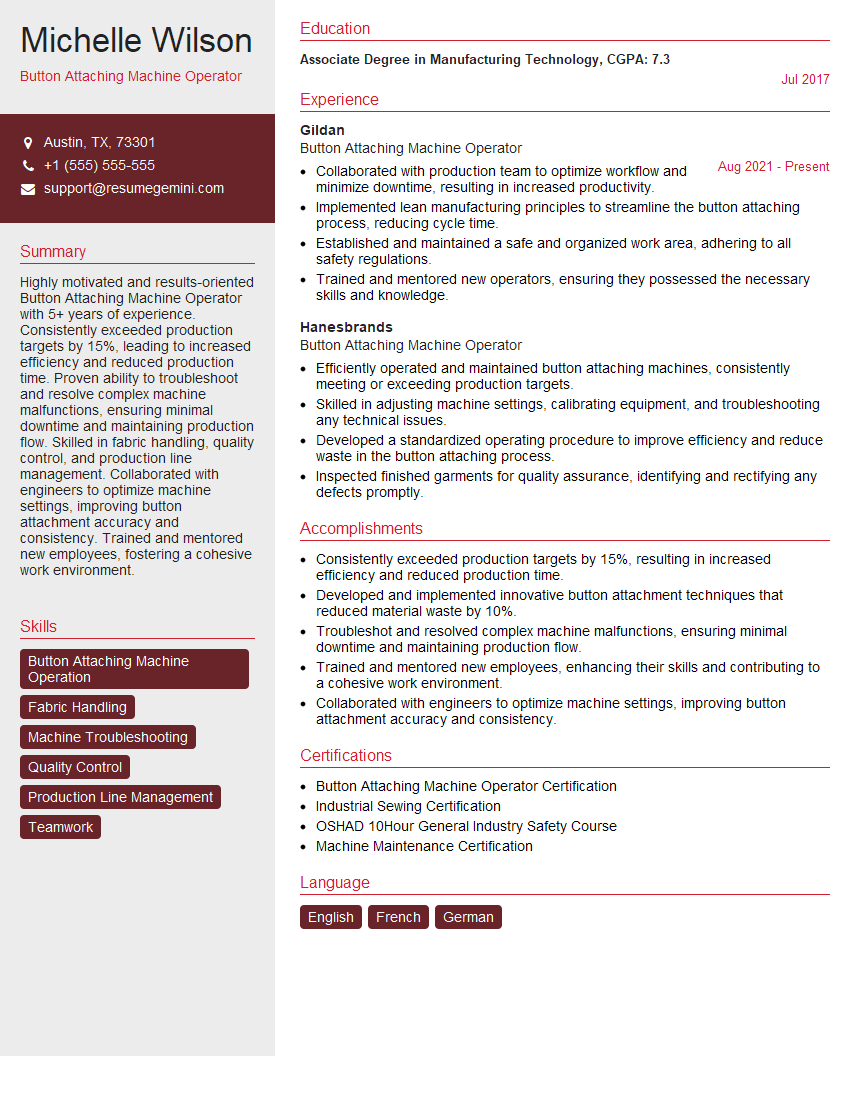

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Button Attaching Machine Operator

1. What is the importance of maintaining the correct tension in the thread used by the button attaching machine?

Maintaining the correct thread tension is crucial for several reasons:

- Stitch Quality: Proper tension ensures strong and secure stitches, preventing button detachment or puckering.

- Machine Performance: Correct tension reduces thread breakage and minimizes machine downtime, ensuring efficient operation.

- Fabric Protection: Excessive tension can damage the fabric, while insufficient tension may result in loose stitches.

- Button Appearance: Proper tension creates a neat and professional appearance of the attached buttons.

2. Describe the process of troubleshooting a button attaching machine that is producing uneven stitches.

Identifying the Cause:

- Check thread tension: Ensure it is set correctly for the fabric and thread type.

- Inspect the needle: Verify that it is the right size and not bent or damaged.

- Examine the bobbin: Make sure it is properly seated and contains thread of suitable quality.

- Clean the machine: Remove any lint or debris that may be obstructing the stitching path.

Resolving the Issue:

- Adjust thread tension as needed.

- Replace the needle if necessary.

- Check and replace the bobbin if required.

- Thoroughly clean the machine to remove any obstructions.

- Check the machine settings to ensure they are suitable for the fabric and button type being used.

3. How do you ensure that the buttons are attached to the garments at the correct position and height?

To ensure accurate button placement:

- Use a template: Create a template or jig to mark the exact button placement on each garment.

- Calibrate the machine: Set the machine guide or attachment to match the template markings.

- Check alignment: Before attaching the buttons, double-check the alignment using the template or a ruler.

- Use consistent pressure: Apply consistent pressure while attaching the buttons to ensure uniform height and security.

4. What are the safety precautions that you should observe while operating a button attaching machine?

Safety precautions include:

- Wear appropriate clothing: Loose clothing or jewelry could get caught in the machine.

- Secure hair and loose items: Tie long hair back and remove any loose items that could interfere with operation.

- Keep hands away from moving parts: Avoid touching the needle, presser foot, or other moving components.

- Unplug the machine before performing maintenance: Always disconnect the power before attempting any adjustments or repairs.

- Report any malfunctions or hazards: Immediately report any irregularities, such as unusual noises or vibrations, to the supervisor.

5. How do you handle garments with delicate fabrics when attaching buttons?

Handling delicate fabrics requires care:

- Use a fine needle: Select a needle size appropriate for the fabric weight and type.

- Reduce thread tension: Lower the thread tension to minimize fabric damage.

- Use a stabilizer: Apply a lightweight stabilizer to support the fabric during stitching.

- Handle gently: Handle the garment with care to avoid snags or tears.

6. What is the difference between a straight stitch and a zigzag stitch when attaching buttons?

Straight Stitch:

- Produces a linear, straight line of stitches.

- Suitable for attaching smaller, flat buttons that do not require reinforcement.

Zigzag Stitch:

- Creates a zigzagged line of stitches.

- Provides greater strength and stability for attaching larger or heavier buttons.

7. Describe the maintenance procedures you follow to keep the button attaching machine in good working condition.

Maintenance procedures include:

- Daily cleaning: Remove lint and debris from the machine head and table.

- Weekly lubrication: Apply lubricant to designated points according to the manufacturer’s instructions.

- Monthly inspection: Check for worn or damaged parts, such as needles, thread guides, and belts.

- Regular servicing: Arrange for professional servicing by a qualified technician as recommended by the manufacturer.

8. How do you ensure that the buttons are attached securely and will not detach during use or washing?

To ensure secure button attachment:

- Use high-quality thread: Select a strong thread that is suitable for the fabric and button type.

- Multiple stitches: Create multiple passes of stitches around the button shank to increase strength.

- Knot the thread: Tie a knot in the thread to prevent unraveling.

- Use a shank: Attach shank buttons to create a space between the button and the fabric, allowing for easier buttoning and preventing fabric damage.

9. What is the importance of maintaining a clean and organized workspace when operating a button attaching machine?

Maintaining a clean workspace has several benefits:

- Efficiency: A clean workspace allows for quick access to materials, reducing downtime.

- Safety: Eliminating clutter prevents tripping hazards and reduces the risk of accidents.

- Machine performance: Keeping the machine area clean helps prevent dust and debris from entering the machine, ensuring optimal performance.

- Quality: A clean workspace promotes focus and attention to detail, leading to higher-quality button attachment.

10. How would you handle a situation where the machine malfunctions and you are unable to resolve the issue yourself?

If the machine malfunctions:

- Stop the machine immediately: Prevent further damage and safety hazards.

- Identify the problem: Check for obvious issues, such as a loose thread or broken needle.

- Refer to the user manual: Consult the manufacturer’s instructions for troubleshooting steps.

- Contact the supervisor or maintenance personnel: Report the issue and request assistance.

- Do not attempt complex repairs yourself: Leave major repairs to qualified technicians.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Button Attaching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Button Attaching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Button Attaching Machine Operators are responsible for operating and maintaining button attaching machines in a manufacturing environment. Their primary duty is to ensure that buttons are attached to garments or other products efficiently and accurately.

1. Machine Operation

Operate button attaching machines to attach buttons to garments or other products.

- Set up and adjust machine settings to ensure proper button attachment.

- Load garments or materials into the machine and remove finished products.

2. Quality Control

Inspect finished products to ensure that buttons are attached securely and meet quality standards.

- Identify and correct any defects or errors in button attachment.

- Maintain records of quality checks and inspections.

3. Maintenance

Perform basic maintenance and troubleshooting on button attaching machines.

- Clean and lubricate machine components.

- Replace worn or damaged parts.

4. Production Monitoring

Monitor production output and identify areas for improvement.

- Keep track of production targets and deadlines.

- Suggest changes to improve efficiency and productivity.

Interview Tips

Preparing well for the interview is crucial in acing it. Here are some tips to help:

1. Research the Company and Position

Thoroughly research the company, its values, and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the opportunity.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses thoughtfully. Practice delivering your answers clearly and concisely.

3. Highlight Your Skills and Experience

Focus on showcasing your relevant skills and experience that align with the job requirements. Use specific examples to demonstrate your abilities.

4. Be Enthusiastic and Confident

Convey a positive and enthusiastic attitude throughout the interview. Confidence in your abilities will make a lasting impression on the interviewer.

5. Ask Questions

Prepare thoughtful questions to ask the interviewer. This indicates your engagement and interest. Questions about the company, team, or role can provide valuable insights.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Button Attaching Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.