Are you gearing up for an interview for a Button Facing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Button Facing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

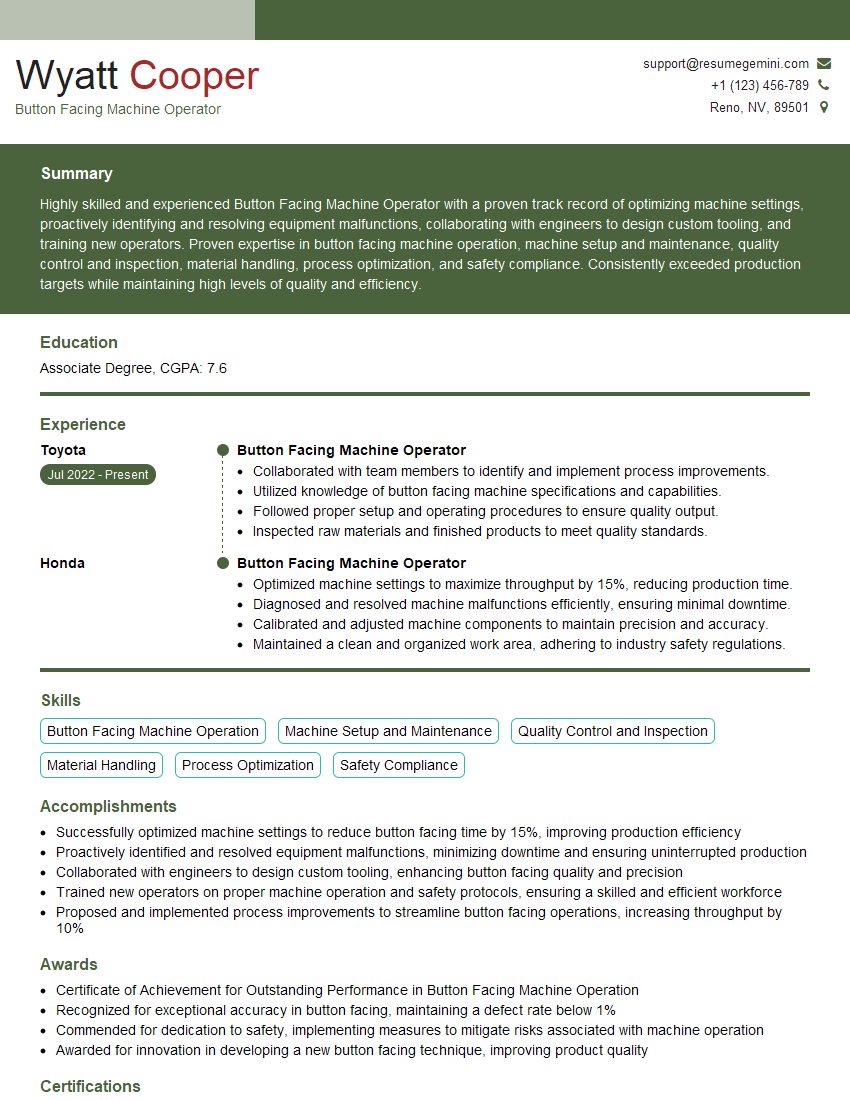

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Button Facing Machine Operator

1. What are the key responsibilities of a Button Facing Machine Operator?

- Monitoring and operating button facing machines to produce high-quality button faces

- Setting up and adjusting machine to ensure optimal performance and efficiency

- Inspecting finished button faces to confirm they meet specifications and quality standards

- Troubleshooting and resolving machine malfunctions to minimize downtime and maintain productivity

- Maintaining a clean and organized work area, adhering to safety regulations and procedures

2. Describe the different types of Button Facing Machines and their applications.

- Horizontal Button Facing Machine: Used for facing buttons on flat surfaces, suitable for high-volume production.

- Vertical Button Facing Machine: Designed for facing buttons on cylindrical or curved surfaces, providing greater precision.

- CNC Button Facing Machine: Computer-controlled machines offering high accuracy, flexibility, and automation.

3. What are the critical quality parameters to consider when facing buttons?

- Button Diameter: Ensuring the button faces are consistent with the specified diameter.

- Button Thickness: Maintaining the desired thickness of the button faces.

- Surface Finish: Achieving a smooth and uniform surface finish on the button faces.

- Edge Quality: Ensuring the edges of the button faces are clean and free of burrs or imperfections.

- Material Compatibility: Selecting the appropriate tooling and parameters based on the material of the buttons.

4. How do you ensure that the Button Facing Machine is calibrated and maintained for optimal performance?

- Regular Inspections: Conducting routine inspections to identify any signs of wear or damage.

- Calibration Checks: Utilizing calibration tools to ensure the machine is operating within specified tolerances.

- Preventative Maintenance: Performing scheduled maintenance tasks, such as cleaning, lubrication, and adjustments.

- Tooling Management: Inspecting and replacing tooling periodically to maintain cutting efficiency.

- Collaboration with Maintenance Team: Communicating maintenance needs and coordinating with the maintenance team for repairs or major overhauls.

5. What are the safety precautions to observe when operating Button Facing Machines?

- Machine Guarding: Ensuring all safety guards are in place and functional.

- Eye Protection: Wearing safety glasses or goggles to protect eyes from flying debris.

- Noise Protection: Utilizing earplugs or ear muffs to minimize exposure to excessive noise.

- Proper Clothing: Wearing appropriate clothing that does not get caught in the machine.

- Emergency Stop: Knowing the location and operation of the emergency stop button.

6. Describe your experience in troubleshooting common issues with Button Facing Machines.

- Button Faces Not Meeting Specifications: Adjusting machine settings, checking tooling condition, and ensuring proper material selection.

- Excessive Vibration or Noise: Inspecting machine components for loose parts, worn bearings, or unbalanced tooling.

- Machine Malfunction: Diagnosing electrical or mechanical issues, replacing faulty components, and consulting with maintenance personnel.

- Tool Breakage: Identifying the cause of tool breakage (e.g., incorrect cutting parameters, material hardness) and taking corrective action.

- Production Bottlenecks: Analyzing workflow, identifying inefficiencies, and implementing solutions to improve productivity.

7. How do you manage production schedules and ensure timely delivery of high-quality button faces?

- Production Planning: Reviewing production orders, estimating machine setup time, and scheduling tasks.

- Material Management: Coordinating with suppliers to ensure timely delivery of raw materials.

- Quality Control: Conducting regular inspections and implementing quality control measures to meet customer specifications.

- Communication and Coordination: Collaborating with colleagues, supervisors, and customers to address any issues or changes.

- Prioritization and Flexibility: Prioritizing orders based on urgency and adjusting schedules as needed to accommodate changes in demand.

8. Describe your knowledge of different tooling materials used in Button Facing Machines and their applications.

- Carbide: High hardness and wear resistance, suitable for facing hard materials like steel.

- High-Speed Steel (HSS): Offers a balance of toughness and cutting performance, commonly used for softer materials.

- Ceramic: Extreme hardness and heat resistance, ideal for facing brittle materials like glass.

- Diamond: Exceptional cutting ability and longevity, utilized for precision facing of hard materials.

9. How do you maintain a clean and organized work area around the Button Facing Machine?

- Regular Cleaning: Cleaning the machine, tooling, and surrounding area periodically.

- Waste Management: Disposing of scrap materials and button faces in designated containers.

- Tool Storage: Organizing and storing tooling properly to prevent damage and ensure accessibility.

- Workstation Ergonomics: Maintaining a well-organized and ergonomic workspace to enhance efficiency and reduce fatigue.

- Safety Compliance: Adhering to company policies and safety regulations related to workplace cleanliness.

10. What motivates you to excel as a Button Facing Machine Operator?

- Precision and Quality: Drive to produce high-quality button faces that meet or exceed customer specifications.

- Problem-Solving: Enjoyment in troubleshooting and resolving machine issues to maintain optimal performance.

- Attention to Detail: Passion for meticulous work and ensuring the accuracy of every button face.

- Continuous Improvement: Eagerness to learn new techniques and implement improvements to enhance productivity.

- Teamwork and Collaboration: Appreciation for working as part of a team and contributing to the overall success of the production line.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Button Facing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Button Facing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Button Facing Machine Operator, you play a vital role in the manufacturing process, ensuring the precise and efficient production of button faces.

1. Machine Operation

Operate and calibrate button facing machines to face (machine) fabric-covered buttons to a specified diameter, bevel, and thickness.

2. Production Monitoring

Monitor machine performance, adjust settings, and maintain production speeds to optimize output.

Conduct regular inspections to ensure that buttons meet quality standards.

3. Maintenance and Troubleshooting

Perform maintenance tasks such as lubricating, cleaning, and minor repairs on the button facing machine.

Identify and resolve operational issues quickly to minimize downtime.

4. Material Management

Handle and load materials, such as button blanks and fabric.

Monitor material inventory and report any shortages.

Interview Tips

Impressing the interviewer and showcasing your skills as a Button Facing Machine Operator requires both technical knowledge and professional preparation.

1. Research the Company and Role

Gather information about the company’s history, values, and products, and the specific requirements of the Button Facing Machine Operator role.

2. Highlight Relevant Experience

Demonstrate your proficiency in operating button facing machines, including the ability to calibrate settings, monitor production, and perform maintenance.

Provide specific examples of your contributions to improve production efficiency or quality.

3. Demonstrate Attention to Detail

Emphasize your meticulous nature and keen eye for detail, which are essential for producing high-quality button faces.

Describe how you maintain a clean and organized work area and follow safety protocols.

4. Show Enthusiasm and Willingness to Learn

Convey your passion for precision manufacturing and your eagerness to continue developing your skills.

Inquire about any opportunities for training or professional development within the organization.

5. Prepare Questions

Prepare thoughtful questions to ask the interviewer, showing your engagement and interest in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Button Facing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.