Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Button Maker and Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

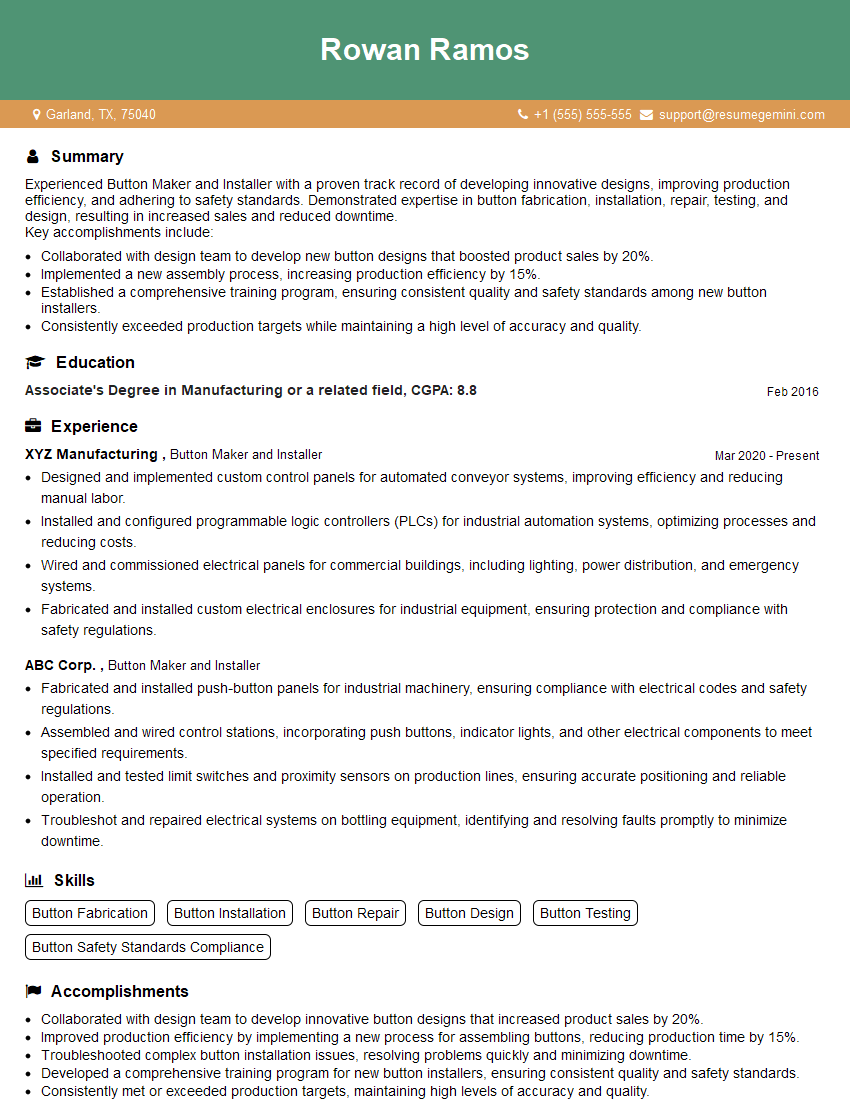

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Button Maker and Installer

1. Describe the steps involved in creating a custom button?

The process of creating a custom button involves the following steps:

- Gather requirements from the customer, including the size, shape, style, color, and any special features.

- Design the button using a computer-aided design (CAD) program.

- Create a prototype of the button using a 3D printer or other prototyping method.

- Produce the button using a mold, die, or other manufacturing process.

- Assemble the button, including adding any necessary hardware, such as a shank or pin.

- Inspect the button to ensure that it meets the customer’s requirements.

2. What are the different types of button materials?

- Metal: Metal buttons are durable and can be made from a variety of metals, including brass, aluminum, and stainless steel.

- Plastic: Plastic buttons are lightweight and inexpensive, and they can be made in a wide variety of colors and shapes.

- Wood: Wood buttons are natural and durable, and they can be stained or painted to match any décor.

- Fabric: Fabric buttons are soft and can be made from a variety of materials, including cotton, linen, and silk.

- Glass: Glass buttons are beautiful and delicate, and they can be made in a variety of colors and shapes.

3. What are the different types of button shanks?

- Wire shank: Wire shanks are made from a thin wire that is wrapped around the back of the button.

- Loop shank: Loop shanks are made from a small loop of wire that is attached to the back of the button.

- Flat shank: Flat shanks are made from a flat piece of metal that is attached to the back of the button.

- Self-shank: Self-shanks are made from a single piece of plastic or metal that is molded into the back of the button.

4. What are the different types of button installation methods?

- Sew-on: Sew-on buttons are attached to fabric using thread.

- Glue-on: Glue-on buttons are attached to fabric using glue.

- Snap-on: Snap-on buttons are attached to fabric using a snap fastener.

- Riveting: Riveting buttons are attached to fabric using a rivet.

5. What are the common problems that can occur during button installation and how do you troubleshoot them?

- The button is loose: The button may be loose if the thread or glue is not strong enough. To fix this, reattach the button using stronger thread or glue.

- The button is crooked: The button may be crooked if it was not installed correctly. To fix this, remove the button and reinstall it, making sure that it is aligned correctly.

- The button is damaged: The button may be damaged if it was not handled properly. To fix this, replace the button with a new one.

6. What are the latest trends in button design?

The latest trends in button design include:

- Minimalism: Buttons are becoming more minimalist, with simple shapes and clean lines.

- Sustainability: Buttons are being made from more sustainable materials, such as recycled plastic and wood.

- Customization: Buttons are becoming more customizable, with customers able to choose from a variety of colors, shapes, and sizes.

- Technology: Buttons are becoming more technologically advanced, with features such as LED lights and touchscreens.

7. What are the different types of button making machines?

- Hand-operated button making machines: Hand-operated button making machines are small and portable, and they are ideal for small-scale button production.

- Semi-automatic button making machines: Semi-automatic button making machines are larger and more powerful than hand-operated machines, and they can produce buttons more quickly and efficiently.

- Automatic button making machines: Automatic button making machines are the most advanced and efficient type of button making machine, and they can produce large quantities of buttons quickly and easily.

8. How do you maintain a button making machine?

To maintain a button making machine, you should:

- Clean the machine regularly with a soft cloth and mild detergent.

- Lubricate the moving parts of the machine with a light oil.

- Inspect the machine regularly for wear and tear, and replace any damaged parts as needed.

9. What are the safety precautions that should be taken when operating a button making machine?

- Always wear safety glasses when operating a button making machine.

- Keep your hands away from the moving parts of the machine.

- Do not operate the machine if it is damaged or malfunctioning.

- Follow the manufacturer’s instructions for operating the machine.

10. What are the different types of button installations?

- Surface mount: Surface mount buttons are mounted directly onto the surface of a circuit board.

- Through-hole mount: Through-hole mount buttons are mounted through holes in a circuit board.

- Panel mount: Panel mount buttons are mounted on a panel, such as a front panel or control panel.

- PC board mount: PC board mount buttons are mounted on a printed circuit board.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Button Maker and Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Button Maker and Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Button Maker and Installer

A Button Maker and Installer is responsible for the production and installation of buttons and badges. They work with clients to design and create custom buttons, and then install them on clothing, hats, backpacks, and other items. The key job responsibilities include:- Operate button-making machines to produce buttons and badges

- Design and create custom buttons and badges

- Install buttons and badges on clothing, hats, backpacks, and other items

- Maintain and repair button-making machines

- Work with clients to determine their needs and specifications

- Provide excellent customer service

- Meet production deadlines

Interview Preparation Tips for Button Maker and Installer

To ace an interview for a Button Maker and Installer position, it is important to prepare thoroughly. Here are some tips to help you succeed:- Research the company and the position. This will help you understand the company’s culture, values, and what they are looking for in a Button Maker and Installer.

- Practice answering common interview questions. There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice answering these questions so that you can deliver clear and concise responses.

- Be prepared to talk about your experience and skills. The interviewer will want to know about your experience making and installing buttons and badges. Be sure to highlight your skills and experience in your resume and cover letter, and be prepared to talk about them in detail during your interview.

- Be enthusiastic and positive. Interviewers are looking for candidates who are excited about the position and who are confident in their abilities. Be sure to convey your enthusiasm and passion for button making and installing during your interview.

- Dress professionally and arrive on time for your interview. First impressions matter, so be sure to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Button Maker and Installer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.