Are you gearing up for an interview for a Button Sewing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Button Sewing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

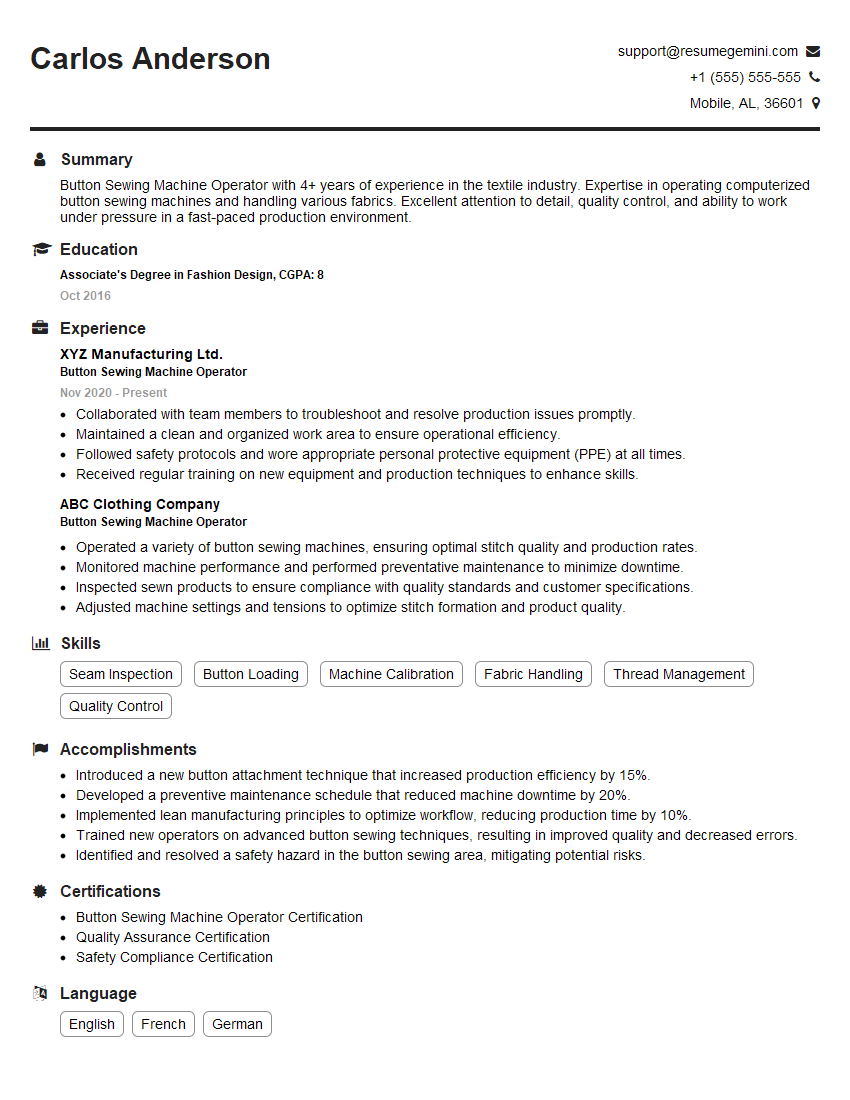

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Button Sewing Machine Operator

1. What are the different types of button sewing machines and their key features?

There are two main types of button sewing machines: single-needle and double-needle. Single-needle machines are used for sewing on flat buttons, while double-needle machines are used for sewing on shank buttons. Here are some of the key features of each type of machine:

- Single-needle machines are typically smaller and more portable than double-needle machines. They are also less expensive.

- Double-needle machines are more powerful than single-needle machines and can sew on thicker materials. They are also more versatile and can be used to sew on a variety of different types of buttons.

2. What are the different types of buttonhole stitches and when would you use each type?

Straight stitch buttonholes

- These are the most common type of buttonhole stitch. They are simple to sew and can be used on a variety of different fabrics.

- They are typically used for sewing on flat buttons.

Zigzag stitch buttonholes

- These buttonholes are more durable than straight stitch buttonholes and are less likely to stretch or tear.

- They are typically used for sewing on shank buttons or on fabrics that are likely to be stressed.

Satin stitch buttonholes

- These buttonholes are the most decorative type of buttonhole stitch. They are more difficult to sew than straight stitch or zigzag stitch buttonholes, but they can be very beautiful.

- They are typically used for sewing on decorative buttons or on garments that are meant to be seen.

3. How do you adjust the tension on a button sewing machine?

The tension on a button sewing machine is adjusted by turning the tension dial. The tension dial is typically located on the side of the machine. Turning the dial clockwise will increase the tension, while turning it counterclockwise will decrease the tension. The correct tension will vary depending on the type of fabric and thread being used.

4. How do you thread a button sewing machine?

To thread a button sewing machine, follow these steps:

- Raise the needle to its highest position.

- Open the bobbin case and insert the bobbin.

- Pull the thread through the tension discs.

- Thread the needle.

- Close the bobbin case.

5. How do you sew on a button with a button sewing machine?

To sew on a button with a button sewing machine, follow these steps:

- Place the button on the fabric in the desired location.

- Lower the needle into the fabric next to the button.

- Turn the handwheel to sew the button in place.

- Tie off the thread and trim the excess.

6. How do you troubleshoot a button sewing machine that is not sewing properly?

If your button sewing machine is not sewing properly, there are a few things you can check:

- Make sure that the machine is properly threaded.

- Check the tension dial to make sure that the tension is set correctly.

- Make sure that the needle is the correct size for the fabric and thread being used.

- If the machine is still not sewing properly, you may need to take it to a qualified technician for repair.

7. What are the safety precautions that should be taken when operating a button sewing machine?

Here are some safety precautions that should be taken when operating a button sewing machine:

- Always wear safety glasses when operating the machine.

- Keep your hands away from the needle and other moving parts.

- Do not operate the machine if it is damaged or not working properly.

- Unplug the machine before making any adjustments or repairs.

8. What is your experience with sewing on different types of fabrics and materials?

I have experience sewing on a variety of different fabrics and materials, including cotton, silk, wool, leather, and denim. I am also familiar with sewing on delicate fabrics, such as lace and chiffon.

9. Do you have any experience with operating different types of button sewing machines?

I have experience operating both single-needle and double-needle button sewing machines. I am also familiar with the different types of buttonhole stitches and how to adjust the tension on the machine.

10. What is your availability to work?

I am available to work full-time, part-time, or on a flexible schedule. I am also available to work weekends and holidays if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Button Sewing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Button Sewing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Button Sewing Machine Operators are vital members of the garment manufacturing team, responsible for sewing buttons onto clothing items with precision and efficiency. Their key responsibilities include:

1. Button Sewing

The primary responsibility is to operate a button sewing machine to attach buttons to garments according to specified designs and quality standards.

- Set up and operate the sewing machine to ensure optimal performance.

- Inspect garments and buttons to ensure they meet quality requirements before sewing.

- Attach buttons using the correct thread color, stitch type, and tension.

- Monitor the sewing process to ensure consistent button placement and secure attachment.

- Troubleshoot and resolve any technical issues with the sewing machine.

2. Quality Control

Ensuring the quality of sewn buttons is essential to prevent defects. Operators inspect their work and identify any errors, such as loose threads, uneven stitching, or button placement deviations.

- Inspect garments after sewing to ensure buttons are securely attached and meet quality standards.

- Identify and correct any defects in button placement, stitching, or thread tension.

- Report any quality concerns to the supervisor immediately.

3. Production Goals

Operators work towards achieving production goals by maintaining a steady pace and minimizing downtime. They are expected to meet or exceed targets for button sewing output.

- Meet daily production targets for button sewing efficiency.

- Maintain a clean and organized work area to maximize productivity.

- Collaborate with other team members to ensure smooth production flow.

- Identify and report any issues that may affect production goals.

4. Safety Compliance

Adhering to safety protocols is crucial in a manufacturing environment. Operators follow established safety guidelines to prevent accidents and maintain a safe work environment.

- Follow all safety regulations regarding the operation of sewing machines and handling of materials.

- Wear appropriate safety gear, such as gloves and safety glasses.

- Report any safety hazards or concerns to the supervisor.

- Maintain a clean and organized work area to minimize potential hazards.

- Undergo regular safety training to stay updated on best practices.

Interview Tips

Preparing for a Button Sewing Machine Operator interview requires careful consideration of your skills, experience, and knowledge. Here are some tips to help you ace the interview:

1. Research the Company and the Role

Before the interview, thoroughly research the company you’re applying to and the specific role. This will give you a good understanding of their business, values, and the expectations for the position.

- Visit the company website to learn about their products, services, and culture.

- Read online reviews and articles to gain insights into the company’s reputation and workplace environment.

- Review the job description thoroughly to identify the key responsibilities and qualifications required for the role.

2. Highlight Your Skills and Experience

During the interview, be confident in presenting your skills and experience that align with the job requirements. Use specific examples to showcase your abilities.

- Quantify your achievements whenever possible. For instance, if you’ve consistently exceeded production targets, mention the percentage or number of buttons sewn per hour.

- Emphasize your attention to detail and commitment to quality. Provide examples of how you’ve identified and corrected errors in your work.

- Describe your experience with different types of button sewing machines and your ability to troubleshoot and resolve technical issues.

3. Demonstrate Your Safety Awareness

Safety is a top priority in manufacturing environments. Show the interviewer that you understand and prioritize safety protocols.

- Explain your understanding of the safety guidelines related to sewing machine operation and handling of materials.

- Mention your experience in following safety regulations and maintaining a safe work area.

- If you’ve had any specific safety training or certifications, highlight them.

4. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the role and the company. It’s also an opportunity to clarify any aspects of the job or the company that you may have.

- Ask about the company’s growth plans and future prospects.

- Inquire about opportunities for professional development and advancement within the company.

- Ask for specific details about the production targets and quality standards expected for the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Button Sewing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!