Feeling lost in a sea of interview questions? Landed that dream interview for Buttonhole and Button Sewing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Buttonhole and Button Sewing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

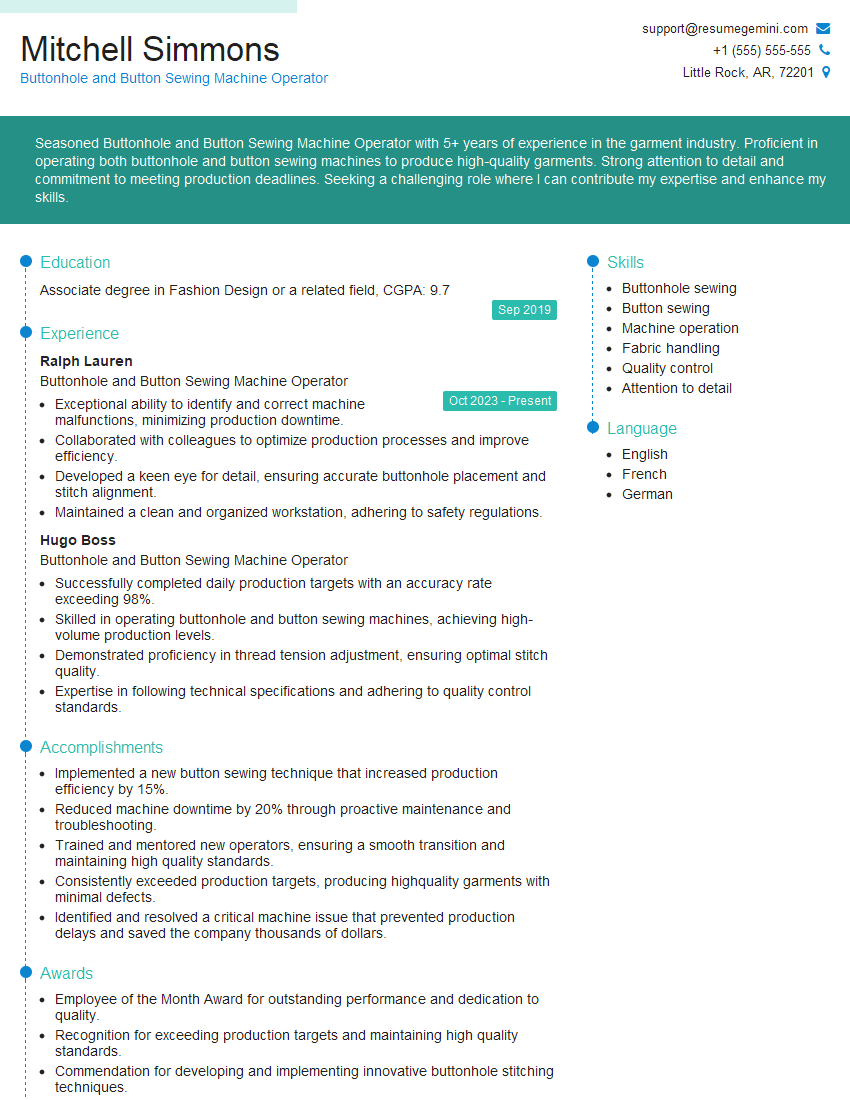

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Buttonhole and Button Sewing Machine Operator

1. What are the different types of buttonhole machines that you have operated?

In my previous role, I have operated a variety of buttonhole machines, including single-needle, double-needle, and programmable buttonhole machines. I am familiar with the different features and capabilities of each type of machine, and I can quickly adapt my skills to operate any buttonhole machine that is required for the job.

2. How do you set up and calibrate a buttonhole machine?

Calibrating the machine

- First, I check the machine’s tension and adjust it as needed.

- Next, I calibrate the machine’s stitch length and width using a test fabric.

- Finally, I check the machine’s needle position and adjust it as needed.

Setting up the machine

- I select the correct buttonhole size and shape for the fabric and garment.

- I then attach the appropriate presser foot and needle.

- Finally, I thread the machine and adjust the tension.

3. How do you troubleshoot common problems that occur when operating a buttonhole machine?

- If the buttonhole is too small or too large, I check the machine’s stitch length and width settings.

- If the buttonhole is not sewn evenly, I check the machine’s tension and needle position.

- If the buttonhole is puckered, I check the fabric’s tension and adjust it as needed.

- If the buttonhole is sewn in the wrong location, I check the machine’s presser foot and needle position.

4. What is the difference between a buttonhole and a button sewing machine?

- A buttonhole machine creates the hole in the fabric where the button will be sewn.

- A button sewing machine sews the button onto the fabric.

5. What are the safety precautions that you need to take when operating a buttonhole machine?

- Always wear safety glasses when operating a buttonhole machine.

- Keep your hands away from the needle.

- Do not operate the machine if it is damaged or if the needle is bent.

- Unplug the machine before making any adjustments.

6. What are the different types of fabrics that you have sewn buttonholes on?

- I have sewn buttonholes on a variety of fabrics, including cotton, linen, silk, wool, and denim.

- I am familiar with the different properties of each type of fabric and I can adjust my sewing techniques accordingly.

7. What is the most challenging aspect of operating a buttonhole machine?

- The most challenging aspect of operating a buttonhole machine is ensuring that the buttonholes are sewn evenly and consistently.

- This requires a great deal of precision and attention to detail.

8. What is your favorite thing about operating a buttonhole machine?

- My favorite thing about operating a buttonhole machine is the satisfaction of creating a beautiful and functional buttonhole.

- I also enjoy the challenge of working with different fabrics and creating buttonholes that are unique to each garment.

9. What are your career goals?

- My career goal is to become a master buttonhole machine operator.

- I want to continue to develop my skills and knowledge in this field.

- I also want to become a more efficient and productive operator.

10. Why should we hire you for this position?

- I am a highly skilled and experienced buttonhole machine operator.

- I am confident that I can meet the demands of this position and exceed your expectations.

- I am also a hard worker and I am always willing to learn new things.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Buttonhole and Button Sewing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Buttonhole and Button Sewing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Buttonhole and Button Sewing Machine Operator is responsible for operating machines that sew buttonholes and attach buttons to garments or other fabric items. The primary responsibilities include:

1. Machine Operation

Operate and maintain buttonhole and button sewing machines to create buttonholes and attach buttons on various fabric items.

2. Quality Control

Inspect the finished products for quality, ensuring that the buttonholes and buttons are properly sewn and meet company standards.

3. Material Handling

Handle and load fabric items into the machines, ensuring proper alignment and positioning for accurate sewing.

4. Production Monitoring

Monitor the production process and make adjustments to the machines as needed to maintain productivity and efficiency.

Interview Tips

To ace an interview for a Buttonhole and Button Sewing Machine Operator position, candidates should prepare thoroughly and present themselves professionally. Here are some essential tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and the specific job requirements. This will demonstrate your interest and enthusiasm for the position.

2. Highlight Relevant Skills

Emphasize your proficiency in operating buttonhole and button sewing machines. Showcase your attention to detail and ability to produce high-quality work.

3. Prepare Examples

Provide specific examples of your experience in operating sewing machines, handling materials, and maintaining quality standards.

4. Practice Common Interview Questions

Anticipate typical interview questions and prepare answers that highlight your skills, experience, and suitability for the role.

5. Be Enthusiastic and Show Your Passion

Convey your passion for the trade and willingness to learn and contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Buttonhole and Button Sewing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!