Feeling lost in a sea of interview questions? Landed that dream interview for Byproduct Engineer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Byproduct Engineer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

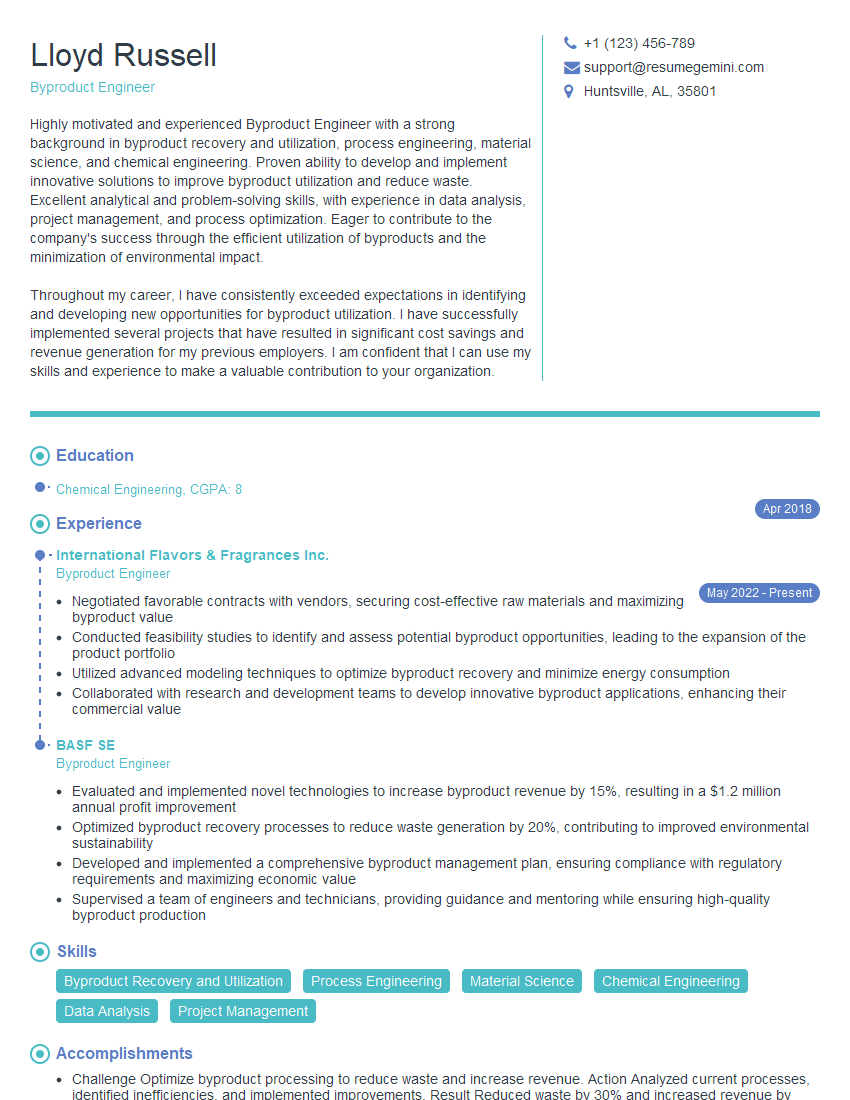

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Byproduct Engineer

1. Describe the role of a byproduct engineer in the manufacturing process?

As a byproduct engineer, I am responsible for:

- Identifying and evaluating potential byproducts from manufacturing processes

- Developing and optimizing processes for capturing and utilizing byproducts

- Ensuring compliance with environmental regulations and industry best practices in byproduct management

- Collaborating with other departments to maximize the value of byproducts and minimize waste

- Staying up-to-date on emerging technologies and trends in byproduct utilization

2. What is process flow diagram (PFD)? How is it used in byproduct engineering?

Understanding Process Flow Diagrams

- PFDs are graphical representations of a chemical process, showing the flow of materials and energy

- They include information on process equipment, piping, instrumentation, and control systems

Role in Byproduct Engineering

- Byproduct engineers use PFDs to identify potential sources of byproducts

- They analyze flow rates and material balances to determine the quantity and quality of byproducts that can be captured

- PFDs also help in designing and optimizing processes for byproduct utilization

3. Explain the concept of heat integration in byproduct engineering?

Heat integration involves the efficient use of heat energy within a manufacturing process.

- Byproduct engineers identify opportunities to recover heat from process streams and use it to heat other streams

- This reduces energy consumption and improves process efficiency

- Heat integration can also be used to generate steam or hot water for other purposes within the plant

4. Describe the methods for evaluating the economic feasibility of byproduct utilization projects?

Evaluating the economic feasibility of byproduct utilization projects involves:

- Estimating the capital and operating costs of the project

- Forecasting the revenue that can be generated from byproduct sales

- Performing a financial analysis to determine the project’s profitability

- Considering factors such as payback period, internal rate of return, and net present value

5. How do you stay up-to-date with the latest developments in byproduct utilization technologies?

To stay up-to-date with the latest developments in byproduct utilization technologies, I:

- Attend industry conferences and workshops

- Read technical journals and articles

- Network with other engineers and researchers

- participate in online forums and discussion groups

6. Describe your experience in designing and implementing a byproduct utilization project?

In my previous role, I led a team that developed and implemented a process to capture and utilize a byproduct stream from a chemical plant.

- We identified the byproduct as a valuable resource that could be sold to other industries

- We designed and installed a system to capture the byproduct and purify it to meet customer specifications

- The project resulted in significant revenue generation and waste reduction for the plant

7. What are the challenges associated with managing byproducts in a manufacturing plant?

Managing byproducts in a manufacturing plant poses several challenges, including:

- Identifying and characterizing byproducts

- Developing cost-effective and sustainable technologies for byproduct utilization

- Meeting environmental regulations and industry best practices

- finding markets for byproducts

8. How do you prioritize byproduct utilization projects in a manufacturing plant?

Prioritizing byproduct utilization projects involves considering factors such as:

- The potential economic value of the byproduct

- The technical feasibility of capturing and utilizing the byproduct

- The environmental impact of the byproduct

- The alignment of the project with the company’s sustainability goals

9. Explain the role of life cycle assessment (LCA) in byproduct engineering?

LCA is a tool that assesses the environmental impacts of a product or process throughout its life cycle

- Byproduct engineers use LCA to evaluate the environmental benefits of byproduct utilization

- LCA can help identify opportunities to reduce the environmental footprint of manufacturing processes

10. Describe your experience in collaborating with other departments to maximize the value of byproducts?

In my previous role, I worked closely with colleagues from various departments including:

- Production to understand the process and identify potential byproducts

- Research and development to explore new technologies for byproduct utilization

- Marketing and sales to find markets for byproducts

- Environmental health and safety to ensure compliance with regulations

This collaboration was essential for successfully developing and implementing byproduct utilization projects

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Byproduct Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Byproduct Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Byproduct Engineers are responsible for the efficient and environmentally sound management of industrial byproducts. Their primary duties include:

1. Waste Reduction and Resource Recovery

Evaluate existing manufacturing processes and identify opportunities to reduce waste generation.

- Develop and implement innovative technologies to convert byproducts into valuable products or raw materials.

- Maximize resource utilization by finding sustainable uses for waste materials.

2. Environmental Compliance and Sustainability

Ensure compliance with all applicable environmental regulations related to byproduct management.

- Develop and implement waste management plans that minimize environmental impact.

- Monitor air, water, and soil quality to ensure compliance with environmental standards.

3. Process Optimization

Analyze byproduct generation processes to identify areas for improvement.

- Develop and implement process modifications to reduce waste output.

- Collaborate with other engineers to optimize plant operations and reduce byproduct generation.

4. Project Management

Lead and coordinate large-scale byproduct management projects.

- Manage budgets, schedules, and project teams.

- Provide technical expertise and guidance throughout the project lifecycle.

Interview Tips

Preparing for a Byproduct Engineer interview requires a comprehensive understanding of the role and the industry. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Thoroughly research the company you’re applying to, their industry, and their approach to byproduct management.

- This will demonstrate your interest in the company and your knowledge of the field.

- Tailor your answers to the specific company and their needs.

2. Highlight Your Technical Expertise

Emphasize your understanding of byproduct management principles and technologies.

- Discuss specific projects or initiatives you’ve led that have successfully reduced waste or improved resource recovery.

- Share your knowledge of environmental regulations and best practices.

3. Demonstrate Your Problem-Solving Skills

Byproduct Engineers need to be able to find creative solutions to complex waste management challenges.

- Describe situations where you’ve analyzed a problem, developed a solution, and implemented it successfully.

- Emphasize your ability to think outside the box and identify innovative solutions.

4. Show Your Passion for Sustainability

Byproduct Engineers play a vital role in environmental protection. Share your passion for sustainability.

- Discuss your involvement in environmental initiatives or organizations.

- Explain how your personal values align with the company’s commitment to sustainability.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Byproduct Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!