Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Byproducts Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

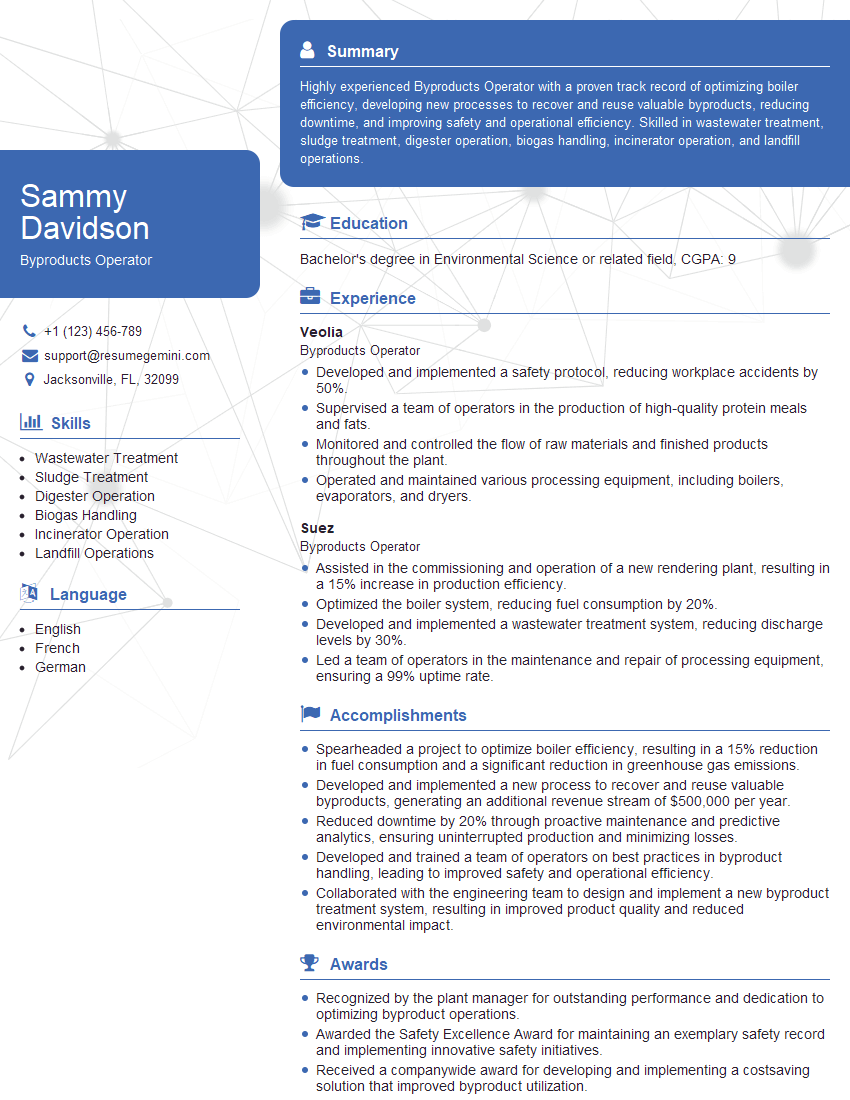

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Byproducts Operator

1. Explain the process of rendering animal byproducts?

The rendering process involves converting animal byproducts, such as bones, fat, and offal, into useful products. It typically involves the following steps:

- Grinding: The byproducts are ground into smaller pieces to facilitate further processing.

- Cooking: The ground material is cooked under pressure and temperature in a rendering tank to separate fat and water from the solids.

- Centrifuging: The cooked material is centrifuged to separate the fat from the solids and water.

- Drying: The solids are dried to remove moisture and produce meat and bone meal.

- Cooling: The dried meal is cooled before it is packaged or stored.

2. Describe the different types of byproducts that can be rendered?

- Animal fats: These are rendered to produce tallow and lard, which can be used in various industries such as food, cosmetics, and pharmaceuticals.

- Meat and bone meal: A dry, ground product used as a protein supplement in animal feed.

- Blood meal: A high-protein powder used as a fertilizer or animal feed additive.

- Feathers and hair: These can be processed into keratin meal, which is used as a fertilizer or in the production of animal feed.

- Organs: Certain organs, such as livers and kidneys, can be rendered to produce pet food or other products.

3. What are the key quality control parameters for rendered products?

- Fat content: The amount of fat present in the rendered product, which affects its nutritional value and use.

- Protein content: The amount of protein present, which is important for products such as meat and bone meal.

- Moisture content: The amount of moisture remaining in the product, which can affect its stability and shelf life.

- Free fatty acid content: The amount of free fatty acids present, which can affect the product’s odor and quality.

- Salmonella and other microbial contamination: The absence of harmful microorganisms to ensure product safety.

4. How do you ensure the safety and efficiency of the rendering process?

Ensuring safety and efficiency in the rendering process involves:

- Adhering to hygiene and sanitation regulations: Maintaining a clean and sanitary work environment to prevent contamination.

- Proper equipment maintenance: Regularly inspecting and maintaining rendering equipment to ensure proper functioning and safety.

- Following established operating procedures: Adhering to standardized protocols for all stages of the rendering process to maintain consistency and quality.

- Monitoring and controlling process parameters: Regularly monitoring and adjusting temperature, pressure, and other process variables to optimize efficiency and product quality.

- Regular testing and analysis: Conducting regular testing of rendered products to ensure they meet quality and safety standards.

5. Describe the environmental regulations and waste management practices in the rendering industry?

The rendering industry is subject to environmental regulations and waste management practices, including:

- Wastewater treatment: Rendering facilities must have systems in place to treat wastewater generated from the process.

- Odor control: Measures such as biofilters and scrubbers are used to control odors emitted during the rendering process.

- Solid waste disposal: Rendering facilities must properly dispose of solid waste, such as bones and other inedible materials, in accordance with regulations.

- Compliance with air quality standards: Facilities must comply with air quality regulations to minimize emissions and protect the environment.

- Adherence to industry best practices: Rendering facilities typically follow industry best practices and guidelines to ensure environmental sustainability.

6. Explain the role of preventive maintenance in a rendering facility?

Preventive maintenance is crucial in a rendering facility for:

- Equipment reliability: Regular maintenance helps to ensure that equipment operates reliably and efficiently, preventing unexpected breakdowns.

- Product quality: Proper maintenance of equipment helps to maintain consistent product quality by preventing contamination or equipment malfunctions.

- Safety: Regular maintenance reduces the risk of accidents or injuries by identifying and addressing potential hazards.

- Cost savings: Preventive maintenance can prevent costly repairs or equipment replacements in the long run.

- Compliance: Maintaining equipment in good working order helps to ensure compliance with safety and environmental regulations.

7. Describe the importance of process automation in a rendering facility?

Process automation in a rendering facility offers several advantages:

- Increased efficiency: Automation can streamline processes, reduce manual labor, and increase overall production efficiency.

- Improved product quality: Automated systems can consistently control process parameters, leading to more uniform and higher-quality products.

- Enhanced safety: Automation can reduce the risk of accidents or injuries by minimizing human involvement in hazardous tasks.

- Cost savings: Automation can reduce labor costs and improve resource utilization, leading to overall cost savings.

- Data collection and analysis: Automated systems can collect and analyze data, providing insights for process optimization and decision-making.

8. What are the key challenges in the rendering industry?

- Raw material variability: The quality and composition of animal byproducts can vary, which can impact the rendering process and product yields.

- Environmental regulations: Stringent environmental regulations require rendering facilities to minimize emissions, wastewater discharge, and solid waste.

- Disease control: Rendering facilities must implement strict biosecurity measures to prevent the spread of animal diseases.

- Market fluctuations: The demand for rendered products can fluctuate based on economic conditions and global market trends.

- Technological advancements: The rendering industry is constantly evolving with new technologies and innovations, requiring facilities to adapt and invest in upgrades.

9. What are the career advancement opportunities for Byproducts Operators?

- Assistant Plant Manager: Supervising production operations and managing staff.

- Production Manager: Overseeing the entire rendering process, ensuring efficiency and product quality.

- Quality Assurance Manager: Developing and implementing quality control programs, ensuring product safety and compliance.

- Environmental Compliance Manager: Ensuring the facility meets environmental regulations and waste management standards.

- Sales Representative: Marketing and selling rendered products to customers in various industries.

10. How do you stay updated with industry trends and best practices?

To stay updated, I engage in the following practices:

- Attending industry conferences and workshops: Networking with peers and learning about new technologies and advancements.

- Reading trade publications and journals: Keeping up with industry news, research, and best practices.

- Participating in online forums and discussion groups: Connecting with other professionals and exchanging knowledge.

- Seeking continuing education opportunities: Pursuing courses or certifications to enhance my skills and knowledge.

- Consulting with experts and vendors: Staying informed about the latest equipment and technologies through industry experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Byproducts Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Byproducts Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Byproducts Operators are responsible for overseeing the efficient operation of byproduct processing equipment and ensuring the production of high-quality finished goods. Their duties encompass a range of tasks, including:

1. Equipment Operation and Maintenance

Operating and maintaining various byproduct processing machines, such as separators, evaporators, and dryers.

- Monitoring equipment performance, identifying potential issues, and taking corrective actions

- Conducting routine maintenance procedures, including cleaning, lubrication, and repairs

2. Process Monitoring and Control

Monitoring and controlling byproduct processing parameters to ensure product quality.

- Ensuring compliance with established process protocols and safety regulations

- Identifying and addressing deviations from standard operating procedures

3. Quality Assurance

Performing quality control tests on finished byproducts and maintaining accurate records.

- Inspecting byproducts for defects or inconsistencies

- Collecting and analyzing data to ensure compliance with quality standards

4. Safety and Compliance

Adhering to all safety regulations and procedures related to byproduct processing.

- Wearing appropriate personal protective equipment (PPE)

- Understanding and following established safety protocols

- Maintaining a clean and organized work environment

Interview Tips

Preparing for an interview for a Byproducts Operator position requires thorough preparation to showcase your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company’s website and industry reputation. Understanding their core business, values, and the specific requirements of the Byproducts Operator role will demonstrate your interest and enthusiasm.

- Identify the key responsibilities of the position and tailor your answers to highlight your relevant skills and experience.

- Practice answering common interview questions related to the industry, your technical abilities, and your approach to safety and quality control.

2. Highlight Your Technical Skills and Experience

Emphasize your technical knowledge and experience in operating and maintaining byproduct processing equipment. Quantify your accomplishments with specific examples.

- Describe your experience in troubleshooting and resolving equipment issues, maximizing efficiency, and minimizing downtime.

- Mention your proficiency in using specialized software or instrumentation for process monitoring and control.

3. Demonstrate Your Commitment to Quality and Safety

Highlight your commitment to producing high-quality byproducts and adhering to safety regulations.

- Provide examples of your attention to detail, accuracy, and precision in performing quality control procedures.

- Explain your understanding of the importance of following established safety protocols and your experience in maintaining a safe and organized work environment.

4. Ask Thoughtful Questions

Prepare insightful questions to ask the interviewer about the company, the position, and the team you’d be joining. This demonstrates your engagement and genuine interest in the opportunity.

5. Follow Up and Express Gratitude

After the interview, promptly follow up with a thank-you note expressing your appreciation for the opportunity and reiterating your interest in the position. If applicable, include any additional information or clarifications that you may have forgotten to mention during the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Byproducts Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Byproducts Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.