Feeling lost in a sea of interview questions? Landed that dream interview for Cable Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cable Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

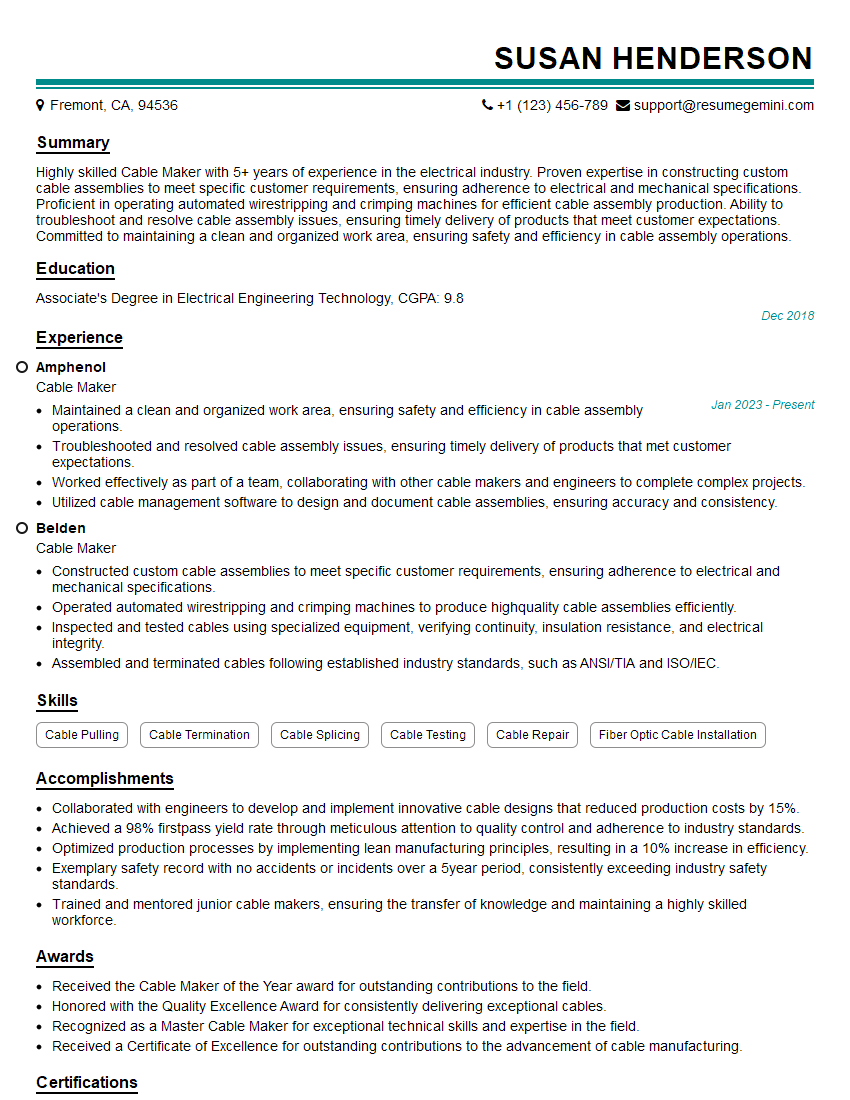

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cable Maker

1. Describe the process of manufacturing a coaxial cable?

The manufacturing process of a coaxial cable involves several steps, including:

- Extrusion: The first step is to extrude the inner conductor, which is typically made of copper. This is done by melting the copper and forcing it through a die to create a long, thin wire.

- Insulation: The inner conductor is then insulated with a layer of dielectric material, such as polyethylene or Teflon. This insulation prevents the inner conductor from coming into contact with the outer conductor and causing a short circuit.

- Shield: A layer of shielding is then applied over the insulation. This shielding is typically made of braided copper or aluminum and helps to protect the cable from electromagnetic interference.

- Outer jacket: The final step is to extrude an outer jacket over the shield. This jacket is typically made of PVC or polyethylene and helps to protect the cable from environmental damage.

2. What are the different types of cable connectors and their applications?

RF connectors

- BNC connectors: These connectors are commonly used in video and RF applications. They are characterized by their bayonet locking mechanism and are available in 50-ohm and 75-ohm versions.

- TNC connectors: These connectors are similar to BNC connectors but have a threaded locking mechanism. They are also used in video and RF applications.

- SMA connectors: These connectors are smaller than BNC and TNC connectors and are used in microwave applications.

Fiber optic connectors

- ST connectors: These connectors are used in single-mode fiber optic applications. They are characterized by their bayonet locking mechanism.

- SC connectors: These connectors are also used in single-mode fiber optic applications. They are characterized by their push-pull locking mechanism.

- LC connectors: These connectors are used in both single-mode and multi-mode fiber optic applications. They are characterized by their small size and push-pull locking mechanism.

Power connectors

- AC power connectors: These connectors are used to connect electrical devices to a power source. They are available in a variety of shapes and sizes.

- DC power connectors: These connectors are used to connect electronic devices to a DC power source. They are also available in a variety of shapes and sizes.

3. Explain the importance of cable testing and the different methods used?

Cable testing is important to ensure that cables are manufactured to specifications and are free of defects. There are a variety of cable testing methods, including:

- Electrical testing: This type of testing measures the electrical properties of a cable, such as its resistance, capacitance, and inductance. Electrical testing can be used to identify defects in the cable’s insulation, conductors, or shielding.

- Mechanical testing: This type of testing measures the mechanical properties of a cable, such as its tensile strength, crush resistance, and flexibility. Mechanical testing can be used to identify defects in the cable’s jacket, shielding, or conductors.

- Environmental testing: This type of testing exposes a cable to a variety of environmental conditions, such as temperature, humidity, and vibration. Environmental testing can be used to identify defects in the cable’s insulation, jacket, or shielding.

4. What are the common problems encountered during cable manufacturing and how do you troubleshoot them?

Some common problems encountered during cable manufacturing include:

- Defects in the insulation: These defects can cause the cable to short circuit or fail prematurely. They can be caused by a variety of factors, such as improper extrusion, contamination, or damage.

- Defects in the conductors: These defects can cause the cable to have a high resistance or to fail prematurely. They can be caused by a variety of factors, such as improper drawing, contamination, or damage.

- Defects in the shielding: These defects can cause the cable to be susceptible to electromagnetic interference. They can be caused by a variety of factors, such as improper application, contamination, or damage.

To troubleshoot these problems, it is important to first identify the cause of the defect. Once the cause has been identified, the appropriate corrective action can be taken.

5. Describe the safety precautions that must be taken when working with cables?

- Always wear appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Be aware of the location of overhead power lines and other potential hazards.

- Use proper lifting techniques when handling heavy cables.

- Never work on live cables.

- Follow all applicable safety regulations.

6. What are the latest trends in cable manufacturing?

- The use of new materials: New materials, such as graphene and carbon fiber, are being used to develop cables that are lighter, stronger, and more durable.

- The development of new technologies: New technologies, such as 3D printing and additive manufacturing, are being used to develop cables that are more complex and customizable.

- The increasing use of automation: Automation is being used to improve the efficiency and quality of cable manufacturing.

7. What are the challenges facing the cable manufacturing industry?

- The rising cost of raw materials: The cost of raw materials, such as copper and aluminum, has been rising in recent years.

- The increasing demand for cables: The demand for cables is growing as more and more devices are connected to the internet.

- The need for more sustainable cables: Customers are increasingly demanding cables that are more sustainable and environmentally friendly.

8. What is your experience with cable manufacturing?

I have over 10 years of experience in cable manufacturing. I have worked in a variety of roles, including production, quality control, and engineering. I have a deep understanding of the cable manufacturing process and the challenges facing the industry.

9. Why are you interested in this position?

I am interested in this position because I am passionate about the cable manufacturing industry. I believe that my skills and experience would be a valuable asset to your company. I am eager to learn more about your company and the challenges that you are facing.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications. I am open to discussing salary during the interview process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cable Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cable Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cable Makers are responsible for the production of electrical cables and wire harnesses. They operate specialized machinery to extrude, insulate, and assemble electrical cables. Additionally, they perform quality-control checks to ensure that the cables meet industry standards.

1. Manufacture Cables

Cable Makers use specialized machinery to manufacture electrical cables. They follow set procedures and specifications to produce cables with the correct dimensions, insulation, and electrical properties.

- Operate extruders to produce cable jackets and insulation

- Apply and wrap insulation materials onto conductors

- Install shielding and protective layers to cables

2. Assemble Wire Harnesses

Cable Makers assemble wire harnesses by connecting individual wires together. They ensure that the wires are routed correctly and secured in place. Wire harnesses are essential components in electrical systems.

- Read and interpret wiring diagrams

- Cut, strip, and terminate wires

- Assemble and bundle wires into harnesses

3. Perform Quality Control

Cable Makers perform quality control checks to ensure that the cables and wire harnesses they produce meet industry standards. They inspect the cables for defects, measure their electrical properties, and test their durability.

- Inspect cables for defects in insulation, shielding, and connectors

- Perform electrical tests to measure resistance, capacitance, and voltage withstand

- Report any non-conforming cables to supervisors

4. Maintenance and Repair

Cable Makers are often responsible for the maintenance and repair of cable-making equipment. They perform routine maintenance tasks, troubleshoot problems, and replace defective parts. This ensures that the equipment is operating efficiently and producing high-quality cables.

- Monitor equipment for signs of wear and tear

- Lubricate and adjust equipment as needed

- Troubleshoot and repair equipment breakdowns

Interview Tips

Interviewing for a Cable Maker position requires a thorough understanding of the job responsibilities and industry knowledge. Here are some tips to help candidates ace the interview:

1. Research the Company and Role

Take the time to research the company and the specific Cable Maker role you are applying for. This will help you understand the company’s culture, values, and expectations for the position.

- Visit the company’s website to learn about their products, services, and values

- Read industry news and articles to stay up-to-date on the latest trends and technologies

- Prepare questions to ask the interviewer about the company and the role

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience in your resume and cover letter. Focus on the key responsibilities of a Cable Maker, such as cable manufacturing, wire harness assembly, quality control, and maintenance.

- Use specific examples to demonstrate your abilities in these areas

- Quantify your accomplishments to show the impact of your work

- Be prepared to discuss your knowledge of cable materials, manufacturing processes, and quality standards

3. Practice Common Interview Questions

Practice answering common interview questions related to the Cable Maker role. This will help you feel more confident and prepared during the actual interview.

- Why are you interested in this Cable Maker position?

- Tell me about your experience in cable manufacturing and wire harness assembly

- How do you ensure the quality of the cables you produce?

- What are some of the challenges you have faced in your previous Cable Maker role?

- How do you stay up-to-date with the latest industry trends and technologies?

4. Dress Professionally and Arrive on Time

Dress professionally for the interview and arrive on time. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear clean, pressed clothes

- Arrive at least 15 minutes early for the interview

- Make eye contact with the interviewer and have a firm handshake

5. Follow Up

After the interview, send a thank-you note to the interviewer. This is an opportunity to reiterate your interest in the position and thank the interviewer for their time.

- Send the thank-you note within 24 hours of the interview

- Re-state your key qualifications and why you are a good fit for the role

- Inquire about the next steps in the hiring process

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cable Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.