Feeling lost in a sea of interview questions? Landed that dream interview for Cable Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cable Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

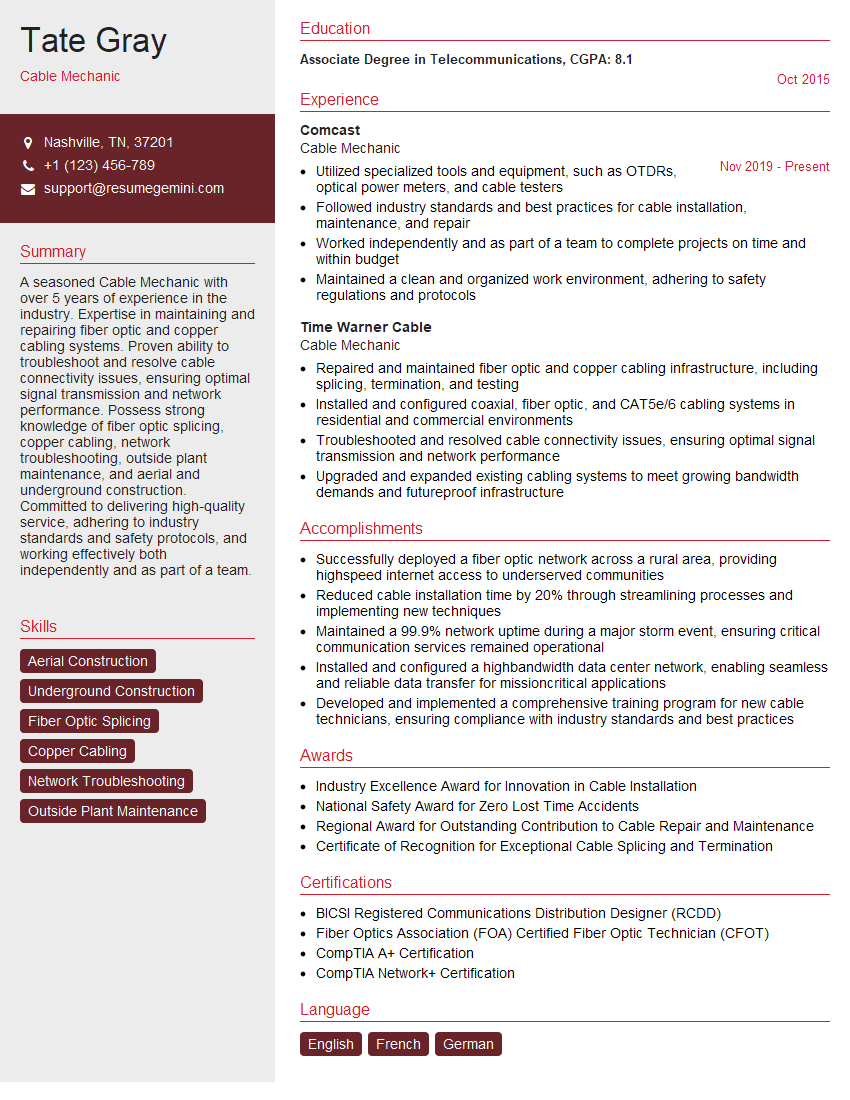

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cable Mechanic

1. Explain the different types of cables used in structured cabling systems?

There are various types of cables used in structured cabling systems. Some common types include:

- Coaxial cable: Used for transmitting data, video, and audio signals. It consists of a central conductor surrounded by insulation and a shielding material.

- Twisted pair cable: Consists of two insulated copper wires twisted together. It is commonly used for telephone and data transmission.

- Fiber optic cable: Transmits data using light pulses instead of electrical signals. It offers high bandwidth and low signal loss.

- Category 5e and Category 6 cables: Used for high-speed data transmission in Ethernet networks.

2. What are the different types of connectors used in structured cabling systems?

There are various types of connectors used in structured cabling systems. Some common types include:

- RJ-45 connectors: Used for connecting Ethernet cables to devices such as computers, switches, and routers.

- RJ-11 connectors: Used for connecting telephone cables to devices such as telephones and modems.

- BNC connectors: Used for connecting coaxial cables to devices such as video cameras and monitors.

- Fiber optic connectors: Used for connecting fiber optic cables to devices such as switches and servers.

3. What are the different types of testing equipment used in structured cabling systems?

There are various types of testing equipment used in structured cabling systems. Some common types include:

- Cable testers: Used to test the continuity, length, and performance of cables.

- Network analyzers: Used to analyze the performance of networks, including bandwidth, latency, and packet loss.

- Tone generators and probes: Used to trace and identify cables within a network.

- Optical time-domain reflectometers (OTDRs): Used to test the performance of fiber optic cables.

4. What are the different types of documentation used in structured cabling systems?

There are various types of documentation used in structured cabling systems. Some common types include:

- As-built drawings: Document the actual layout and installation of the cabling system.

- Cable schedules: List the cables installed, their lengths, and their locations.

- Test reports: Document the results of the testing performed on the cabling system.

- Maintenance logs: Record the maintenance and repair work performed on the cabling system.

5. What are the different types of standards used in structured cabling systems?

There are various standards used in structured cabling systems. Some common standards include:

- TIA/EIA-568-B: Defines the standards for commercial building telecommunications cabling.

- ISO/IEC 11801: Defines the international standards for generic cabling systems.

- ANSI/BICSI 002: Defines the standards for the installation of telecommunications cabling systems.

- UL 444: Defines the safety standards for telecommunications cables.

6. What are the different types of tools used in structured cabling systems?

There are various tools used in structured cabling systems. Some common tools include:

- Cable strippers: Used to remove the outer jacket of cables.

- Crimping tools: Used to attach connectors to cables.

- Punchdown tools: Used to terminate cables onto patch panels.

- Cable ties: Used to organize and secure cables.

7. What are the different types of skills required for a Cable Mechanic?

Some common skills required for a Cable Mechanic include:

- Electrical knowledge: Understanding of electrical principles and concepts.

- Cable installation: Ability to install and terminate various types of cables.

- Connectorization: Ability to attach connectors to cables properly.

- Testing: Ability to test and troubleshoot cabling systems.

- Documentation: Ability to document cabling systems.

8. What are the different types of safety precautions that should be taken when working with structured cabling systems?

There are various safety precautions that should be taken when working with structured cabling systems. Some common precautions include:

- Wear appropriate safety gear: This includes safety glasses, gloves, and hard hat when necessary.

- Follow lockout/tagout procedures: Ensure that power is turned off and equipment is locked out before working on it.

- Use proper tools: Use the correct tools for the job and ensure that they are in good condition.

- Be aware of your surroundings: Pay attention to your surroundings and be aware of potential hazards.

9. What are the different types of troubleshooting techniques used for structured cabling systems?

There are various troubleshooting techniques used for structured cabling systems. Some common techniques include:

- Visual inspection: Check for any obvious damage or loose connections.

- Cable testing: Use a cable tester to check for continuity, length, and performance of cables.

- Network analyzers: Use a network analyzer to analyze the performance of networks, including bandwidth, latency, and packet loss.

- Tone generators and probes: Use a tone generator and probe to trace and identify cables within a network.

10. What are the different types of maintenance procedures that should be performed on structured cabling systems?

There are various maintenance procedures that should be performed on structured cabling systems. Some common procedures include:

- Regular cleaning: Clean cables and connectors to remove dust and debris.

- Cable inspection: Inspect cables for any damage or wear.

- Connector inspection: Inspect connectors for any damage or corrosion.

- Testing: Perform regular testing to ensure that the cabling system is performing properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cable Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cable Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cable Mechanics play a crucial role in maintaining and repairing cable systems, ensuring reliable communication and data transmission.

1. Installation and Maintenance

Install, maintain and repair coaxial and fiber optic cables, connectors, and other related equipment.

- Identify and fix cable faults, ensuring continuity and signal quality.

- Perform preventive maintenance to prevent breakdowns and extend cable life.

2. Network Troubleshooting

Analyze and troubleshoot cable network issues, isolating problems and implementing solutions.

- Use specialized test equipment to locate faults and determine root causes.

- Collaborate with other technicians and engineers to resolve complex network issues.

3. Underground Construction

Install and maintain underground cables, including digging trenches, laying conduits, and connecting cables.

- Follow safety protocols and industry best practices when working with underground cables.

- Ensure proper burial depth and protection of cables from damage.

4. Emergency Response

Respond to emergency situations, such as cable cuts or failures, to restore services promptly.

- Work under pressure and in challenging conditions to ensure quick and efficient resolution.

- Collaborate with emergency crews to ensure public safety and minimize service disruptions.

Interview Tips

Preparing for an interview as a Cable Mechanic requires a combination of technical knowledge, communication skills, and a positive attitude.

1. Research the Company and Position

Visit the company’s website, read industry news, and familiarize yourself with the specific job requirements.

- Identify the company’s goals, values, and service offerings.

- Understand the scope of the Cable Mechanic position and its alignment with your skills.

2. Practice Your Answers

Prepare for common interview questions related to cable installation, maintenance, troubleshooting, and emergency response.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Quantify your accomplishments with specific metrics whenever possible.

3. Highlight Your Technical Skills

Emphasize your knowledge of cable types, installation techniques, and troubleshooting methodologies.

- Discuss your experience working with specific test equipment and software.

- Demonstrate your understanding of industry standards and safety regulations.

4. Showcase Your Problem-Solving Abilities

Provide examples of complex cable issues you have resolved, describing your approach and the outcome.

- Explain your systematic approach to problem identification and solution implementation.

- Highlight your ability to work independently and collaborate effectively.

5. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive attitude throughout the interview.

- Demonstrate your enthusiasm for the cable industry and your eagerness to contribute.

- Ask thoughtful questions to show your interest and engagement.

Next Step:

Now that you’re armed with the knowledge of Cable Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cable Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini