Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cable Mock Up Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cable Mock Up Assembler so you can tailor your answers to impress potential employers.

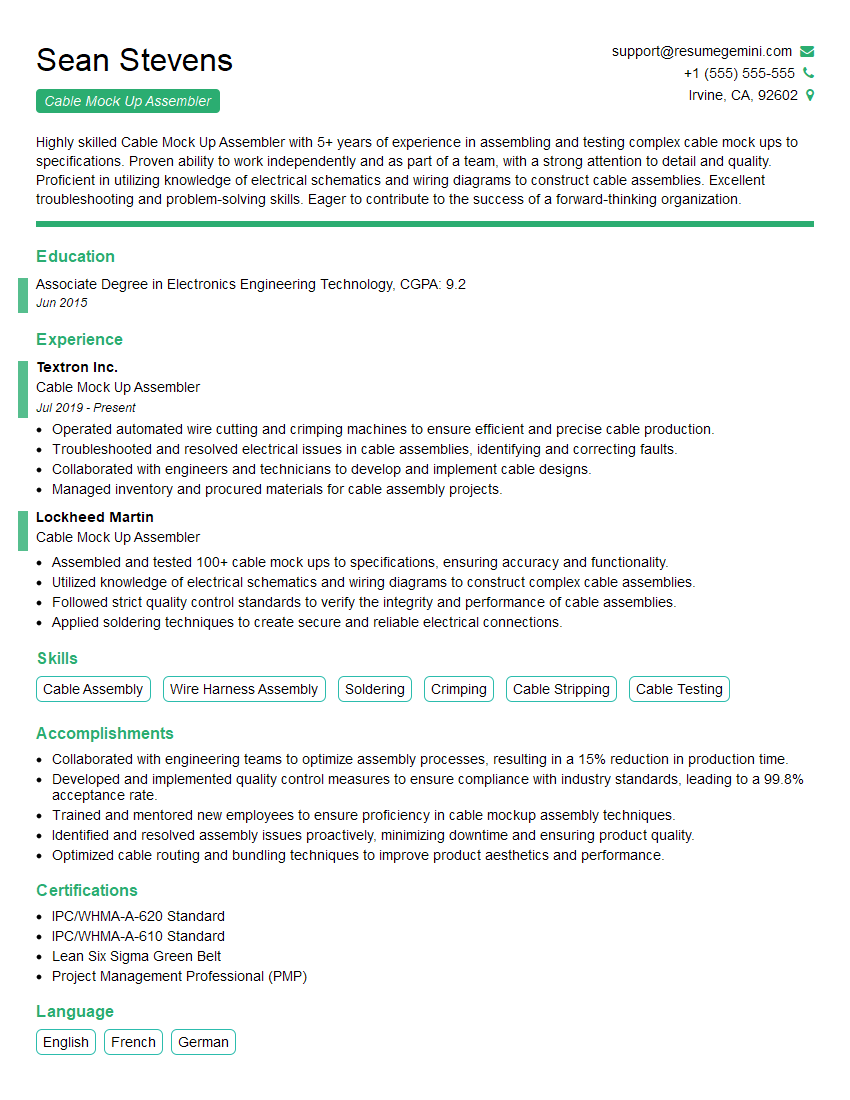

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cable Mock Up Assembler

1. How do you ensure the accuracy and quality of the cable mock-ups you assemble?

To ensure accuracy and quality, I meticulously follow the provided schematics and technical specifications. I thoroughly inspect all materials before assembly, verifying their condition and compatibility. During assembly, I pay meticulous attention to detail, ensuring proper wire routing, secure connections, and adherence to specified tolerances. Additionally, I conduct thorough testing to verify the mock-up’s functionality and compliance with design requirements.

2. Describe your approach to troubleshooting and resolving any issues that arise during cable mock-up assembly.

Identifying the Problem

- Examine the assembly instructions and verify all steps have been followed correctly.

- Inspect the materials and components for any visible defects or inconsistencies.

- Test the mock-up using appropriate tools and equipment to identify any functional issues.

Troubleshooting and Resolution

- Analyze the test results and identify potential causes of the issue.

- Re-assemble the affected section of the mock-up, ensuring proper connections and alignment.

- Replace any faulty materials or components as necessary.

- Re-test the mock-up to verify the issue has been resolved.

3. How do you stay updated on the latest industry standards and best practices for cable mock-up assembly?

To stay informed about industry advancements, I actively participate in professional development opportunities such as workshops, seminars, and online courses. I also regularly review technical publications, industry journals, and manufacturer specifications. Additionally, I engage in discussions with colleagues and attend industry events to exchange knowledge and learn about emerging trends and best practices in cable mock-up assembly.

4. What safety precautions do you take when working with electrical components during cable mock-up assembly?

- Wear appropriate personal protective equipment such as safety glasses, gloves, and non-conductive shoes.

- Verify that the work area is well-ventilated and free from potential hazards.

- Use insulated tools and handle electrical components with care to prevent shocks.

- Follow proper grounding and anti-static measures to minimize the risk of electrostatic discharge.

- Be aware of the location of emergency shut-off switches and know how to use them in case of an accident.

5. Describe your experience with different types of cable assemblies and the techniques you use for each.

- Fiber optic cables: Precision handling, proper termination techniques, and optical testing.

- Coaxial cables: Ensuring proper impedance matching, shielding, and connector installation.

- Twisted pair cables: Adhering to color coding standards, maintaining proper twists, and terminating using punch-down tools or connectors.

- Ribbon cables: Handling with care to avoid damage, using specialized connectors and assembly techniques.

- High-frequency cables: Employing low-loss materials, maintaining tight tolerances, and minimizing signal reflections.

6. How do you manage multiple projects simultaneously and ensure timely delivery of high-quality mock-ups?

To effectively manage multiple projects, I prioritize tasks based on deadlines and project criticality. I create detailed work schedules and allocate resources accordingly. I regularly communicate with team members to ensure coordination and timely progress updates. I also utilize project management tools and techniques to track project status, identify potential bottlenecks, and implement corrective actions as needed. This approach enables me to deliver high-quality mock-ups within the established timelines.

7. Describe a challenging cable mock-up assembly project you worked on and how you overcame the difficulties.

In a recent project involving a complex multi-layer cable mock-up, I encountered challenges related to tight tolerances and the integration of multiple cable types. To overcome these challenges, I consulted with senior engineers and collaborated with the design team to optimize the design and material selection. I also implemented innovative assembly techniques to achieve the required precision. By carefully planning each step of the assembly process and employing meticulous quality control measures, I successfully delivered a high-quality mock-up that met the client’s expectations.

8. How do you handle situations where there are discrepancies between the cable mock-up requirements and the available materials or components?

When faced with discrepancies between mock-up requirements and available materials or components, I promptly communicate the issue to the project team. I provide detailed information about the discrepancies, including any potential impacts on the mock-up’s functionality or timeline. I work closely with the team to explore alternative solutions, such as sourcing compatible materials, modifying the design, or adapting assembly techniques. By proactively addressing discrepancies and collaborating with the team, I ensure that the final mock-up meets the intended specifications.

9. What is your understanding of impedance matching in high-frequency cable assemblies?

Impedance matching in high-frequency cable assemblies is crucial to minimize signal reflections and ensure efficient power transfer. I understand that impedance is the ratio of voltage to current in a circuit and that it must be matched between the cable, connectors, and devices to prevent signal distortion and energy loss. I employ techniques such as using matched connectors, maintaining consistent cable lengths, and avoiding sharp bends to achieve proper impedance matching. This ensures reliable data transmission and optimal performance of high-frequency systems.

10. How do you stay organized and ensure that all necessary documentation for each cable mock-up assembly project is complete and up-to-date?

Maintaining organization and complete documentation is essential. I establish a systematic approach for each project, creating a dedicated folder for all project-related documents, including assembly instructions, schematics, test results, and any communication. I regularly update these documents as the project progresses, ensuring that everyone involved has access to the most recent information. I also utilize project management tools or spreadsheets to track project status, milestones, and any outstanding tasks. This organized approach allows for efficient project execution and ensures that all documentation is readily available for reference or audits.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cable Mock Up Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cable Mock Up Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cable Mock Up Assemblers play a pivotal role in the manufacturing of electrical systems by assembling and testing cable harnesses and mock-ups. Their key responsibilities include:

1. Cable Assembly

Meticulously assembling cable harnesses and mock-ups according to engineering specifications and industry standards.

- Selecting and cutting appropriate cables and wires.

- Stripping, crimping, and soldering connections with precision.

- Assembling components, such as connectors, terminals, and sleeves.

2. Quality Assurance

Maintaining the highest standards of quality by inspecting and testing assembled harnesses and mock-ups.

- Conducting visual inspections for defects and workmanship issues.

- Performing electrical tests to verify continuity, resistance, and insulation integrity.

- Identifying and correcting any errors or discrepancies.

3. Documentation and Record Keeping

Accurately documenting and maintaining records of assembly processes and test results.

- Completing work orders and inspection reports.

- Maintaining assembly instructions and technical specifications.

- Reporting any deviations from specifications or identified defects.

4. Safety and Compliance

Adhering to all safety regulations and industry standards to ensure a safe work environment.

- Wearing appropriate personal protective equipment (PPE).

- Following established safety protocols and procedures.

- Maintaining a clean and organized work area.

Interview Tips

To ace an interview for a Cable Mock Up Assembler position, candidates should:

1. Research the Company and Industry

Demonstrate knowledge of the company’s products, services, and reputation.

- Research the specific industry and its current trends.

- Identify the company’s competitors and market position.

2. Highlight Relevant Skills and Experience

Emphasize previous experience in cable assembly, quality assurance, and electrical testing.

- Quantify accomplishments and provide specific examples of successful projects.

- Discuss your understanding of industry standards and regulations.

3. Prepare for Technical Questions

Expect questions about your knowledge of cable assembly techniques, electrical testing procedures, and troubleshooting methodologies.

- Review common cable types, connectors, and soldering techniques.

- Be familiar with electrical testing equipment and their use.

4. Show Enthusiasm and Motivation

Convey your passion for the role and your desire to contribute to the company’s success.

- Express your interest in the company’s products or services.

- Explain how your skills and experience align with the company’s needs.

Next Step:

Now that you’re armed with the knowledge of Cable Mock Up Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cable Mock Up Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini