Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cable Reeler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

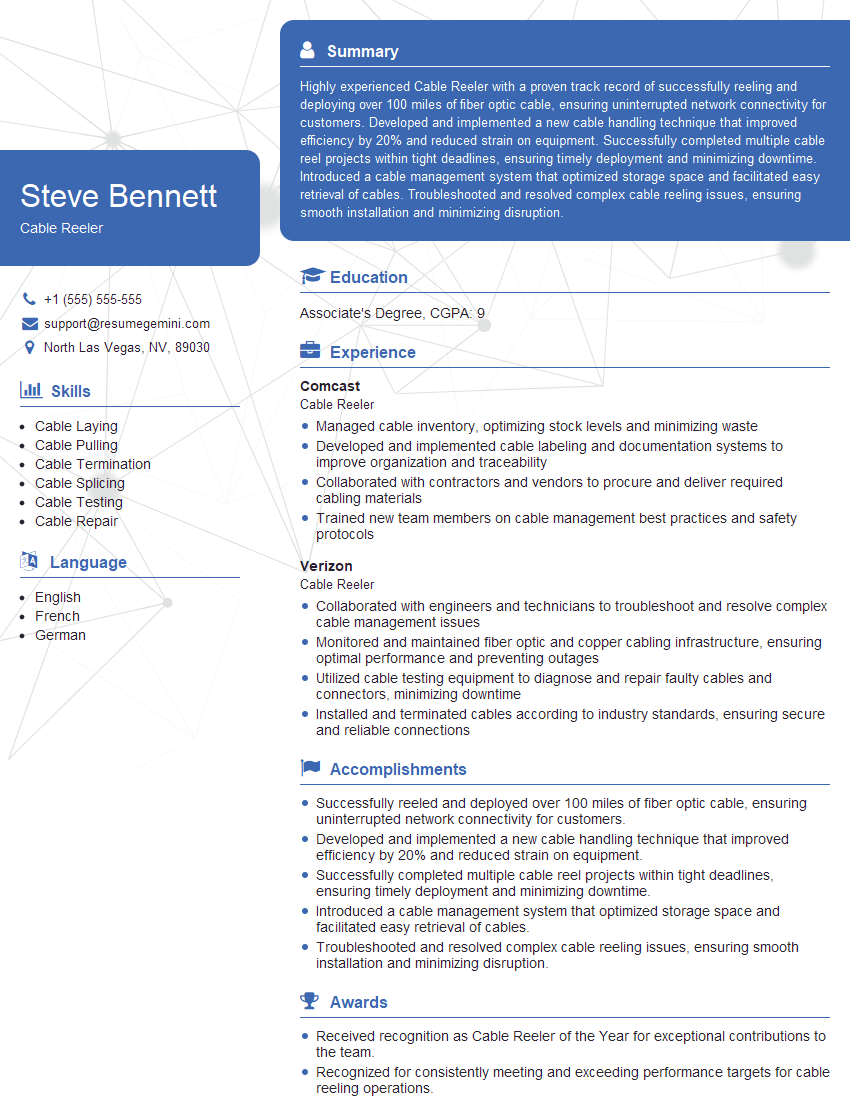

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cable Reeler

1. Explain the different types of cable reels and their applications?

There are various types of cable reels, each designed for specific applications:

- Standard Cable Reels: General-purpose reels for storing and transporting cables in industries, construction, and events.

- Spring-Loaded Reels: Reels that automatically rewind cables using a spring mechanism, ideal for retractable applications like power tools and lighting systems.

- Slip Ring Reels: Reels that allow continuous rotation of cables while maintaining electrical connectivity, used in machinery, robotics, and wind turbines.

- Industrial Reels: Heavy-duty reels for large cables and high-power applications, such as in manufacturing plants and power distribution.

- Portable Reels: Lightweight and compact reels for easy transportation and deployment, often used for temporary installations or events.

2. What are the key factors to consider when selecting a cable reel?

Factors to consider:

- Cable Capacity: The reel must accommodate the required length and diameter of the cable.

- Load Capacity: The reel must be able to support the weight of the cable.

- Applications: Consider the specific application, such as static storage, retractable use, or continuous rotation.

- Materials: Choose materials that are durable, resistant to corrosion, and suitable for the environment.

- Safety Features: Look for reels with features like cable guides, locking mechanisms, and grounding options.

Materials used in cable reels:

- Steel: Durable and strong, for high-load applications.

- Aluminum: Lightweight and corrosion-resistant, for portable or marine use.

- Plastic: Economical and lightweight, for less demanding applications.

3. Describe the process of winding and unwinding cables on a reel.

Winding:

- Secure one end of the cable to the reel’s hub.

- Start winding the cable in even layers, using a cable guide to prevent tangles.

- Apply tension to the cable to ensure a snug fit.

- Secure the cable end once it reaches the desired length.

Unwinding:

- Release the cable end and guide it through the cable outlet.

- Unwind the cable evenly, avoiding kinks or damage.

- Maintain tension to prevent the cable from becoming loose.

- Coil the unwound cable neatly, or use a payout reel.

4. What are the safety precautions to take when handling cable reels?

- Wear proper safety gear, including gloves and safety glasses.

- Ensure the reel is stable and on a level surface.

- Avoid overloading the reel.

- Never stand directly in front of the reel while winding or unwinding.

- Use a cable guide to prevent tangles and injuries.

- Inspect the cable and reel regularly for damage or wear.

- Follow proper grounding procedures to prevent electrical hazards.

- Be aware of the surrounding environment and potential tripping hazards.

5. Explain the maintenance and troubleshooting procedures for cable reels.

Maintenance:

- Regularly clean and inspect the reel and cable for corrosion, damage, or wear.

- Lubricate moving parts as per the manufacturer’s instructions.

- Inspect electrical connections and grounding to ensure proper functionality.

Troubleshooting:

- Cable Tangling: Check the cable guide and ensure the cable is wound evenly.

- Cable Breakage: Inspect the cable for damage and replace if necessary.

- Electrical Faults: Check connections, grounding, and the cable itself for any issues.

- Winding Resistance: Check for friction in the winding mechanism or lubrication issues.

6. What are the industry standards and regulations that apply to cable reels?

- IEC 61239: International standard covering the design, construction, and testing of cable reels.

- OSHA 1910.139: US Occupational Safety and Health Administration (OSHA) regulation on electrical installations, including cable reels.

- NEC Article 530: National Electrical Code (NEC) standards for installing and using cable reels.

- Local Building Codes: Additional regulations may apply based on local building codes and fire safety requirements.

7. Describe the different techniques for calculating cable length on a reel.

- Manual Method: Unwind the cable fully and measure its length using a measuring tape.

- Diameter Method: Measure the diameter of the reel and the cable, then calculate the length using the formula: Length = (π x Reel Diameter x Cable Diameter) / 12.

- Reel Counter Method: Some reels have built-in counters that display the length of cable unwound.

8. Explain the importance of proper storage and transportation of cable reels.

- Store reels in a dry, well-ventilated area to prevent corrosion.

- Protect reels from direct sunlight or extreme temperatures.

- Use proper handling equipment, such as forklifts or cranes, to safely move reels.

- Secure reels during transportation to prevent movement or damage.

9. What are the key challenges and trends in the cable reel industry?

Challenges:

- Increasing Cable Demand: Rising use of electronic devices and infrastructure driving demand for cables.

- Material Costs: Fluctuations in metal prices can impact reel production costs.

- Environmental Regulations: Growing focus on sustainability and recycling.

Trends:

- Smart Reels: Reels with integrated sensors and communication capabilities for real-time monitoring.

- Lightweight Materials: Use of aluminum and composite materials to reduce reel weight.

- Customizable Options: Reels tailored to specific applications and customer requirements.

10. Describe the development and manufacturing process of cable reels.

- Design: Engineering the reel based on specifications and requirements.

- Materials Procurement: Acquiring raw materials, such as steel or aluminum.

- Fabrication: Cutting, forming, and welding the reel components.

- Finishing: Applying coatings or treatments for corrosion resistance and durability.

- Assembly: Putting together the reel components, including the hub, flanges, and axle.

- Testing: Conducting quality control tests to ensure the reel meets specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cable Reeler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cable Reeler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cable Reelers are responsible for the safe and efficient handling of electrical cables. They play a crucial role in ensuring the proper operation of electrical systems and equipment.

1. Cable Handling and Management

Reelers are responsible for the proper handling of cables throughout the project site. This includes:

- Unloading and loading cables from trucks and storage facilities.

- Laying out cables in designated pathways, trenches, or ducts.

- Pulling cables through conduits or other obstacles.

- Securing cables to supports or structures using cable ties, clamps, or other methods.

- Maintaining proper cable tension and avoiding kinks or damage to the cables.

2. Cable Installation and Termination

Reelers may be required to assist with the installation and termination of cables. This involves:

- Connecting cables to electrical equipment, such as transformers, switchgears, or motors.

- Terminating cables using appropriate connectors or lugs.

- Testing and verifying the integrity of cable connections.

3. Cable Maintenance and Inspection

Reelers are responsible for ongoing maintenance and inspection of cables to ensure their safety and functionality. This includes:

- Regularly inspecting cables for signs of damage, wear, or corrosion.

- Performing electrical tests to check cable continuity and insulation integrity.

- Identifying and repairing any cable faults or issues.

- Maintaining accurate records of cable inspections and maintenance activities.

4. Safety and Compliance

Cable Reelers must adhere to all applicable safety regulations and standards while performing their duties. This includes:

- Using appropriate personal protective equipment (PPE), such as gloves, safety glasses, and hard hats.

- Following safe work practices, such as proper lifting techniques and using barricades for cable handling areas.

- Being aware of electrical hazards and taking necessary precautions to prevent accidents.

- Complying with environmental regulations related to cable handling and disposal.

Interview Tips

Preparing for a cable reeler interview can help you make a strong impression on potential employers and increase your chances of landing the job. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the role. You can find relevant information on the company website, social media pages, and industry publications.

2. Practice Answering Common Interview Questions

There are certain interview questions that are commonly asked for cable reeler positions. Practicing your answers to these questions will help you feel more confident and prepared during the interview. Some common interview questions for cable reelers include:

- Tell me about your experience in handling and managing electrical cables.

- Describe your knowledge of cable installation and termination techniques.

- How do you ensure the safety of yourself and others while working with electrical cables?

- What is your understanding of cable maintenance and inspection procedures?

- How do you handle working in challenging environments or under pressure?

3. Be Prepared to Discuss Your Skills and Experience

During the interview, be prepared to discuss your skills and experience in detail. This includes your technical abilities, such as cable handling, installation, and maintenance, as well as your soft skills, such as communication, teamwork, and problem-solving. Highlight your relevant experiences and provide specific examples to demonstrate your qualifications for the role.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the biggest challenges facing cable reelers in this industry?

- What opportunities are there for professional development within the company?

- What is the company’s approach to safety and compliance?

5. Follow Up After the Interview

After the interview, it is important to follow up with the interviewer within 24-48 hours. This shows that you are still interested in the position and that you appreciate their time. In your follow-up email or letter, thank the interviewer for their time and reiterate your interest in the role. You can also use this opportunity to address any questions or concerns that were not covered during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cable Reeler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.