Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cable Tool Driller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

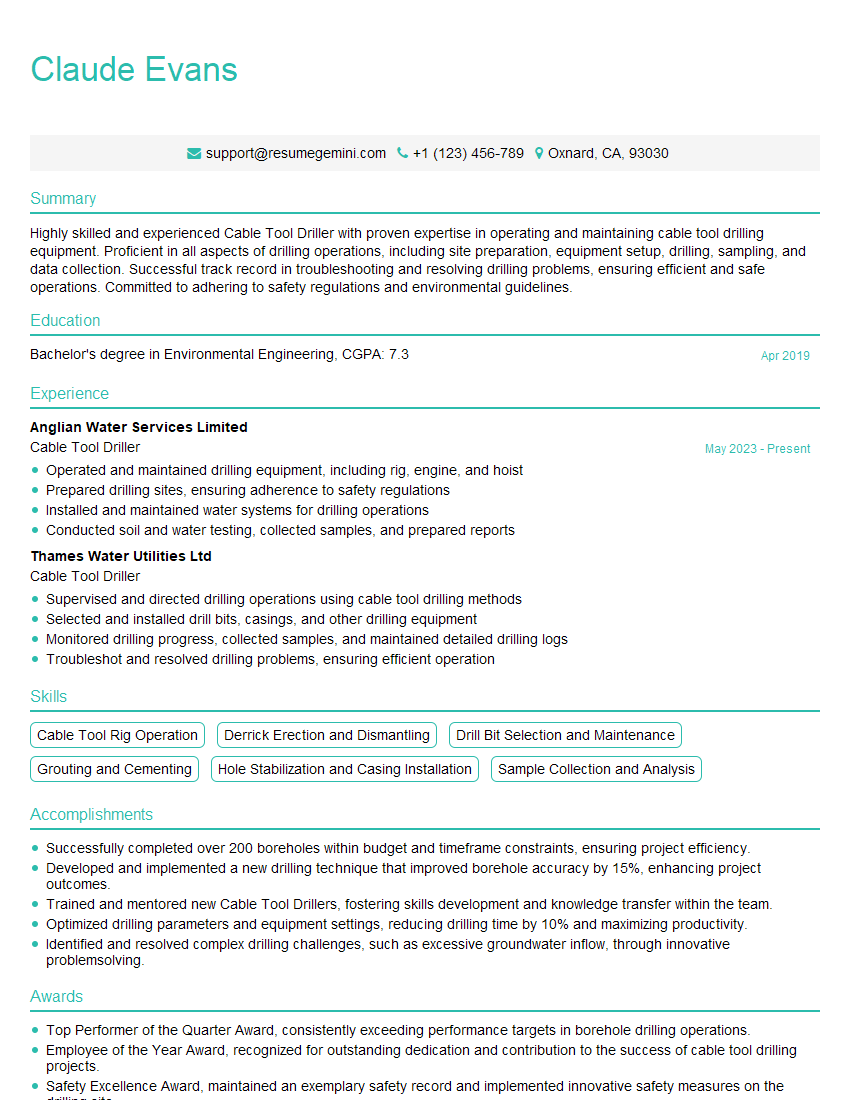

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cable Tool Driller

1. What are the different types of cable tool drilling rigs?

There are three main types of cable tool drilling rigs: standard, rotary, and combination.

- Standard cable tool drilling rigs use a heavy bit attached to a cable to drill the hole. The bit is raised and dropped repeatedly to break up the rock.

- Rotary cable tool drilling rigs use a rotating bit to drill the hole. The bit is attached to a drill pipe which is rotated by a motor.

- Combination cable tool drilling rigs can be used for both standard and rotary drilling. They have a rotating table that can be used to rotate the drill pipe or the cable.

2. What are the main components of a cable tool drilling rig?

- The derrick is a tall, A-shaped structure that supports the drilling equipment.

- The drawworks are a winch that raises and lowers the drilling tools.

- The drilling tools consist of the bit, the drilling stem, and the casing.

- The mud pump circulates drilling fluid through the hole to cool and lubricate the bit and to remove cuttings.

3. What are the different methods of operating a cable tool drilling rig?

- Spudding in is the process of starting the hole. The bit is lowered into the ground and rotated until it drills a hole that is large enough to accommodate the casing.

- Drilling is the process of continuing the hole. The bit is raised and dropped repeatedly to break up the rock and the cuttings are removed by the drilling fluid.

- Casing is the process of lining the hole with pipe to prevent the walls from collapsing.

- Pulling out is the process of removing the drilling tools from the hole.

4. What are the safety hazards associated with cable tool drilling?

- Falling objects can cause serious injury or death.

- Rotating equipment can catch clothing or body parts and cause serious injury.

- Drilling fluid can be hazardous if it is ingested or comes into contact with the skin.

- Noise from the drilling rig can cause hearing loss.

- Vibration from the drilling rig can cause fatigue and other health problems.

5. What are the precautions that should be taken when operating a cable tool drilling rig?

- Wear appropriate safety gear, including hard hat, safety glasses, and gloves.

- Be aware of your surroundings and be careful not to trip or fall.

- Keep a safe distance from rotating equipment.

- Do not come into contact with drilling fluid.

- Use hearing protection to reduce the risk of hearing loss.

- Take breaks to reduce the risk of fatigue.

6. What are the maintenance requirements for a cable tool drilling rig?

- Regularly inspect the drilling rig for any damage or wear.

- Lubricate the moving parts of the rig.

- Replace worn parts as needed.

- Store the rig in a dry place when it is not in use.

7. What are the troubleshooting tips for cable tool drilling?

- If the bit is not drilling, check the bit for wear or damage.

- If the drilling fluid is not circulating, check the mud pump for any problems.

- If the casing is not going down, check the casing for any damage.

- If the drilling rig is vibrating excessively, check the rig for any loose bolts or nuts.

- If the drilling rig is making a loud noise, check the rig for any loose or worn parts.

8. What are the advantages of using a cable tool drilling rig?

- Cable tool drilling rigs are relatively simple to operate.

- Cable tool drilling rigs are relatively inexpensive to purchase and maintain.

- Cable tool drilling rigs can be used in a variety of soil and rock conditions.

- Cable tool drilling rigs can be used to drill deep holes.

9. What are the disadvantages of using a cable tool drilling rig?

- Cable tool drilling rigs are slow to operate.

- Cable tool drilling rigs can be difficult to control in unstable soil or rock conditions.

- Cable tool drilling rigs can produce a lot of noise and vibration.

10. What are the applications of cable tool drilling?

- Cable tool drilling rigs are used to drill water wells.

- Cable tool drilling rigs are used to drill oil and gas wells.

- Cable tool drilling rigs are used to drill geothermal wells.

- Cable tool drilling rigs are used to drill mineral exploration holes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cable Tool Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cable Tool Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cable Tool Drillers operate and maintain cable tool drilling rigs to drill holes for water wells, mineral exploration, and other purposes. They use a variety of tools and techniques to drill through different types of soil and rock.

1. Drilling Operations

Cable Tool Drillers are responsible for all aspects of drilling operations, including:

- Setting up and operating the cable tool drilling rig

- Selecting the appropriate drilling tools and techniques for the job

- Monitoring the drilling progress and making adjustments as needed

- Ensuring that the drilling operation is safe and efficient

2. Maintenance and Repair

Cable Tool Drillers are also responsible for maintaining and repairing their drilling equipment. This includes:

- Inspecting and servicing the drilling rig regularly

- Replacing worn or damaged parts

- Troubleshooting and repairing any problems that may arise

3. Safety and Environmental Compliance

Cable Tool Drillers must always work in a safe and environmentally responsible manner. This includes:

- Following all safety regulations and guidelines

- Protecting the environment from drilling-related hazards

4. Other Duties

In addition to the above, Cable Tool Drillers may also be responsible for:

- Assisting with well development and testing

- Providing customer service

- Keeping records of drilling operations

Interview Tips

Preparing for your Cable Tool Driller interview is essential to making a good impression and increasing your chances of getting the job. Here are a few tips to help you prepare:

1. Research the Company

Before your interview, take some time to research the company you’re applying to. This will help you understand their business, their culture, and their specific needs.

2. Practice Your Answers

Once you’ve done your research, start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview. Some common questions you may be asked include:

- Tell me about your experience with cable tool drilling.

- What are your strengths and weaknesses as a Cable Tool Driller?

- Why are you interested in working for this company?

3. Dress Professionally

The way you dress for your interview can make a big impression. Dress professionally and conservatively, and make sure your clothes are clean and pressed.

4. Be on Time

Punctuality is important for any job interview, but it’s especially important for a Cable Tool Driller interview. This is because drilling rigs are often located in remote areas, and the interviewer may have to travel a long way to meet you.

5. Be Enthusiastic

Cable Tool Drilling is a demanding job, so it’s important to be enthusiastic about the work. Let the interviewer know that you’re passionate about drilling and that you’re eager to learn more about the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cable Tool Driller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!