Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cadmium Liquor Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

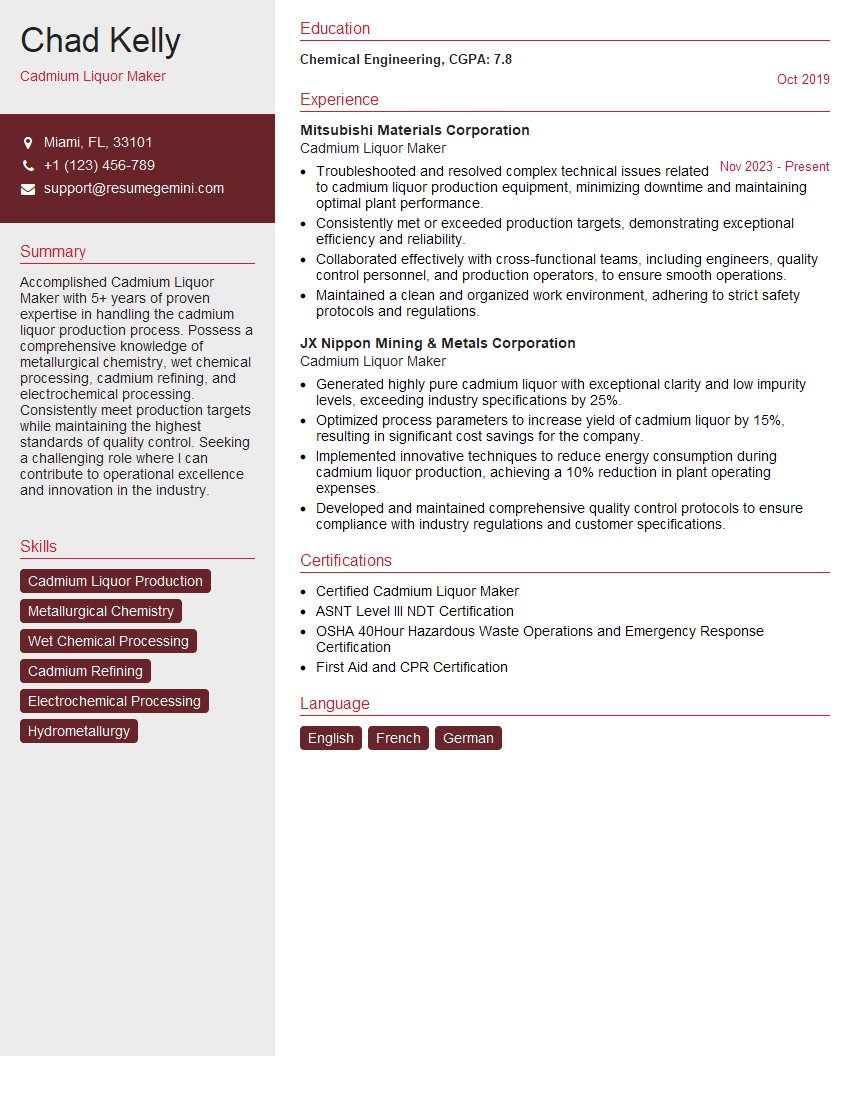

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cadmium Liquor Maker

1. how to efficiently manage multiple Cadmium liquor making processes simultaneously?

To manage multiple Cadmium liquor making processes simultaneously, I would prioritize tasks based on their importance and urgency, utilizing my time management skills to allocate resources effectively.

- Establish clear priorities: Identify the most critical processes and focus on completing them first.

- Create a structured workflow: Plan and schedule tasks, ensuring a smooth flow of production.

- Delegate responsibilities: Assign specific tasks to team members based on their strengths and experience.

- Monitor progress regularly: Track the status of each process to identify any potential bottlenecks or delays.

- Communicate effectively: Maintain open communication with team members and supervisors to provide updates and address challenges promptly.

2. Explain the chemical reactions involved in Cadmium liquor making process and how to control them for optimal results?

key chemical reactions

- Cadmium oxide (CdO) + Carbon monoxide (CO) → Cadmium metal (Cd) + Carbon dioxide (CO2)

- Cadmium metal (Cd) + Sulfuric acid (H2SO4) → Cadmium sulfate (CdSO4) + Hydrogen (H2)

controlling the reactions

- Temperature control: Maintaining optimal temperature ranges for each reaction is crucial.

- Stoichiometry control: Ensuring the correct mole ratio of reactants to achieve desired product yield.

- Reaction time optimization: Monitoring reaction progress and adjusting time parameters for optimal conversion.

- Impurity removal: Implementing purification steps to remove impurities that could affect product quality.

- pH monitoring: Controlling pH levels to optimize reaction rates and prevent side reactions.

3. Describe the safety precautions and environmental regulations that must be followed when working with Cadmium liquor?

- Wear appropriate personal protective equipment (PPE), including gloves, respirators, and protective clothing.

- Handle Cadmium liquor in well-ventilated areas to minimize exposure to toxic fumes.

- Follow established waste disposal procedures to prevent environmental contamination.

- Adhere to all relevant safety protocols and guidelines, such as those outlined by OSHA and EPA.

- Regularly monitor Cadmium liquor concentrations to ensure compliance with environmental regulations.

- Stay informed about any updates or changes to safety regulations and best practices.

4. How to troubleshoot common problems that arise during Cadmium liquor making process?

- Identify the problem: Determine the specific issue affecting the process, such as low product yield or impurities.

- Analyze potential causes: Consider various factors that could contribute to the problem, including equipment malfunctions, incorrect process parameters, or raw material quality.

- Implement corrective actions: Develop and execute solutions to address the root cause of the problem, such as adjusting process conditions, replacing faulty equipment, or improving raw material specifications.

- Monitor and evaluate results: Track the effectiveness of implemented solutions and make further adjustments as needed to optimize the process.

- Document and learn: Record the troubleshooting process and its outcomes for future reference and knowledge improvement.

5. Explain the importance of quality control in Cadmium liquor making and how to ensure it?

- Meeting product specifications: Ensure that Cadmium liquor meets established quality standards for purity, concentration, and other relevant parameters.

- Maintaining process consistency: Implement quality control measures to minimize variability in the production process, leading to consistent product quality.

- Reducing waste and rework: Identify and address quality issues early on, preventing defective products and reducing the need for rework or scrap.

- Enhancing customer satisfaction: Delivering high-quality Cadmium liquor contributes to customer satisfaction and loyalty.

- Establishing quality control protocols: Implement standardized procedures for sampling, testing, and data analysis to monitor product quality throughout the process.

6. How to optimize the Cadmium liquor making process to improve efficiency and reduce costs?

- Analyze current process: Conduct a thorough review of the existing process to identify areas for improvement.

- Implement process automation: Automate certain tasks to increase efficiency, reduce labor costs, and improve accuracy.

- Optimize equipment performance: Ensure that equipment is running at optimal conditions and regularly serviced to minimize downtime.

- Utilize advanced technologies: Explore and adopt innovative technologies to enhance process efficiency, such as sensor-based monitoring systems.

- Train operators: Provide comprehensive training to operators on process optimization techniques and best practices.

7. Describe the role of Cadmium liquor in various industries?

- Electroplating: Cadmium liquor is used as an electrolyte in electroplating processes, providing a protective and corrosion-resistant coating.

- Battery manufacturing: Cadmium is used in the production of nickel-cadmium batteries, providing long-lasting power.

- Pigment production: Cadmium compounds are utilized in the manufacturing of pigments for paints and ceramics, offering vibrant and durable colors.

- Stabilizers: Cadmium compounds are employed as stabilizers in plastics, enhancing their resistance to heat and light degradation.

- Catalysis: Cadmium compounds are used as catalysts in various chemical reactions, facilitating specific reactions and improving efficiency.

8. Explain the hazards associated with Cadmium liquor and how to minimize them?

- Toxicity: Cadmium is a toxic substance, and exposure to Cadmium liquor can lead to health issues such as respiratory problems and kidney damage.

- Carcinogenicity: Cadmium is classified as a carcinogen, and prolonged exposure can increase the risk of certain types of cancer.

- Engineering controls: Implement ventilation systems and process enclosures to minimize worker exposure to Cadmium liquor fumes and dust.

- Personal protective equipment (PPE): Provide and ensure the use of appropriate PPE, including respirators, gloves, and protective clothing.

- Hygiene practices: Establish good hygiene practices, such as regular hand washing and avoiding eating or drinking in contaminated areas.

- Medical surveillance: Conduct regular medical surveillance of workers to monitor their health and identify any potential exposure-related issues.

- Emergency response plans: Develop and implement emergency response plans in case of spills or accidents involving Cadmium liquor.

Hazards:

Minimizing hazards:

9. How to dispose of Cadmium liquor in an environmentally responsible manner?

- Neutralization: Neutralize Cadmium liquor with an appropriate neutralizing agent, such as lime or sodium hydroxide, to reduce its toxicity.

- Precipitation: Add a precipitating agent, such as sodium sulfide, to convert Cadmium ions into insoluble Cadmium compounds.

- Detoxification: Treat Cadmium liquor using detoxification processes, such as ion exchange or electrochemical methods, to remove Cadmium and other heavy metals.

- Landfilling: Dispose of solidified or stabilized Cadmium waste in secure landfills designed to prevent environmental contamination.

- Recycling: Explore opportunities for recycling Cadmium-containing materials, such as batteries and electroplating solutions, to minimize waste generation.

10. Explain the concept of “zero liquid discharge” (ZLD) in Cadmium liquor making and its benefits?

- Definition: ZLD is a process that eliminates the discharge of liquid waste by treating and recycling all wastewater generated in a Cadmium liquor making facility.

- Benefits:

- Environmental protection: ZLD prevents the release of Cadmium and other contaminants into the environment, minimizing water pollution.

- Resource conservation: ZLD conserves water resources by recycling and reusing treated wastewater, reducing the need for freshwater intake.

- Cost savings: ZLD can reduce operating costs by eliminating the need for wastewater treatment and disposal.

- Regulatory compliance: ZLD helps facilities comply with increasingly stringent environmental regulations on wastewater discharge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cadmium Liquor Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cadmium Liquor Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cadmium Liquor Makers play a vital role in the battery manufacturing industry. They are responsible for producing cadmium liquor, a critical component in the production of cadmium batteries.

1. Cadmium Recovery

Cadmium Liquor Makers are responsible for recovering cadmium from various sources, such as cadmium-bearing ores and recycled materials.

- Operate and maintain equipment used in cadmium recovery processes.

- Monitor and control process parameters to optimize cadmium recovery efficiency.

2. Cadmium Purification

Once cadmium has been recovered, Cadmium Liquor Makers purify it to meet specific quality standards. This involves removing impurities and ensuring the desired cadmium concentration.

- Operate and maintain purification equipment, such as electrolytic cells and ion exchange columns.

- Conduct chemical analysis to ensure cadmium purity meets specifications.

3. Cadmium Liquor Production

Cadmium Liquor Makers produce cadmium liquor by dissolving purified cadmium in an appropriate solvent, such as sulfuric acid. The concentration of cadmium in the liquor is carefully controlled to meet customer requirements.

- Mix and blend cadmium powder with solvent to produce cadmium liquor.

- Monitor and adjust liquor composition to maintain desired specifications.

4. Quality Control

Cadmium Liquor Makers ensure the quality of cadmium liquor by conducting regular testing and analysis. They monitor impurities, pH, and other parameters to ensure product consistency.

- Perform quality control tests on cadmium liquor using analytical techniques.

- Maintain records and documentation of quality control data.

Interview Tips

To ace your interview for a Cadmium Liquor Maker position, it is crucial to prepare thoroughly. Here are some tips to help you stand out:

1. Research the Company and Industry

Take the time to learn about the company you are applying to and the battery manufacturing industry. Understanding the company’s products, services, and market position will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and read industry publications.

- Network with professionals in the field to gain insights.

2. Highlight Your Technical Skills

Cadmium Liquor Makers require a solid understanding of chemistry, process engineering, and quality control principles. Emphasize your experience in these areas, including:

- Cadmium recovery and purification techniques.

- Electrolytic cell and ion exchange column operation.

- Analytical testing and quality control procedures.

3. Showcase Your Attention to Detail

Producing high-quality cadmium liquor requires meticulous attention to detail. Highlight your ability to follow instructions precisely, monitor process parameters, and maintain accurate records.

- Provide examples of your experience in following complex procedures.

- Describe how you ensure accuracy and precision in your work.

4. Prepare for Behavioral Questions

Interviewers may ask behavioral questions to assess your problem-solving skills, teamwork abilities, and work ethic. Consider potential questions and prepare specific examples from your experiences that demonstrate your strengths.

- Example question: “Tell me about a time when you had to overcome a challenge in the production process.”

- Example response: “In my previous role, I encountered an impurity in the cadmium liquor that was causing quality issues. I conducted a thorough investigation, identified the source of the impurity, and implemented a solution that eliminated the problem.”

5. Practice Your Answers

Confidence is key in any interview. Practice answering common interview questions out loud to improve your delivery and reduce nervousness. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Practice your answers in a mock interview setting with a friend or family member.

- Use the STAR method to provide clear and concise answers.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cadmium Liquor Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cadmium Liquor Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.