Feeling lost in a sea of interview questions? Landed that dream interview for Calcine Furnace Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Calcine Furnace Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

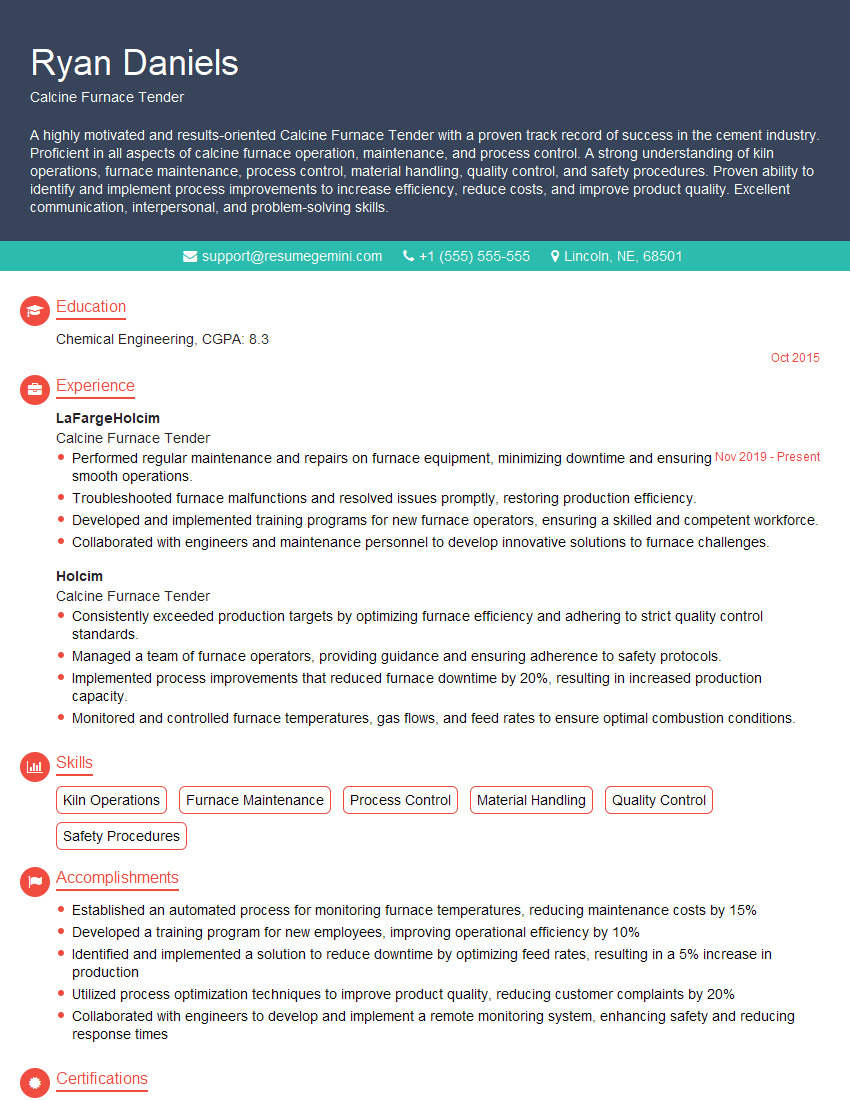

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Calcine Furnace Tender

1. Explain the process of preparing a calcine furnace for operation?

The process of preparing a calcine furnace for operation involves several steps to ensure safe and efficient operation:

- Furnace Inspection: Inspect the furnace, refractory lining, burners, and other components for any damage or defects.

- Preheating: Gradually increase the furnace temperature by firing the burners, allowing the refractory lining to expand and stabilize.

- Loading: Charge the furnace with the appropriate amount and type of feed material, ensuring uniform distribution and proper bed height.

- Ignition: Initiate combustion by turning on the burners and adjusting the fuel-air ratio to achieve the desired temperature profile.

- Temperature Monitoring: Continuously monitor the furnace temperature using thermocouples or pyrometers to ensure it reaches and maintains the desired operating temperature.

2. Describe the key parameters that you monitor and control during the calcination process?

Furnace Temperature:

- Monitor and maintain the furnace temperature within the specified range to ensure efficient calcination and prevent damage to the refractory lining.

- Adjust fuel flow, air flow, or burner settings to regulate the temperature.

Feed Material Flow:

- Control the feed rate to ensure a steady and consistent flow of material through the furnace.

- Monitor feed level sensors or visual indicators to prevent overfeeding or underfeeding.

Fuel-Air Ratio:

- Adjust the fuel-air ratio to maintain optimal combustion conditions and minimize emissions.

- Monitor oxygen levels or flue gas composition to ensure proper air supply.

3. What troubleshooting steps would you take if the furnace temperature is not reaching the desired setpoint?

If the furnace temperature is not reaching the desired setpoint, I would follow these troubleshooting steps:

- Check Fuel Supply: Ensure that the fuel supply is adequate and there are no blockages in the fuel lines or burners.

- Inspect Burners: Check if the burners are functioning properly, free of any obstructions or damage, and properly aligned.

- Air Flow: Verify that the air supply is sufficient and the air flow is properly adjusted to maintain the desired fuel-air ratio.

- Thermocouple Calibration: Ensure that the thermocouples or pyrometers used for temperature measurement are calibrated and providing accurate readings.

- Refractory Insulation: Inspect the refractory lining for any damage or cracks that may lead to heat loss.

4. How do you handle emergencies such as a gas leak or equipment failure during the calcination process?

In case of an emergency, such as a gas leak or equipment failure, I would prioritize the safety of personnel and equipment:

- Immediate Response: Act promptly to isolate the gas leak or stop the equipment and evacuate the area if necessary.

- Notification: Inform the supervisor or designated emergency contact immediately.

- Safety Protocol: Follow established safety protocols, such as using personal protective equipment and contacting emergency services.

- Equipment Assessment: Once the situation is under control, assess the damaged equipment and determine the necessary repairs or replacements.

5. Explain how you ensure the quality of the calcined product meets the required specifications?

To ensure the quality of the calcined product meets the required specifications, I follow these steps:

- Sample Collection: Regularly collect representative samples of the calcined product for quality testing.

- Laboratory Analysis: Send samples to the laboratory for chemical and physical analysis, such as X-ray diffraction, particle size distribution, and chemical composition.

- Data Review: Compare the test results against the established specifications and adjust the process parameters as needed.

- Process Optimization: Based on the analysis, optimize the calcination process to achieve the desired product quality.

6. How do you maintain and calibrate the equipment used in the calcination process?

To maintain and calibrate the equipment used in the calcination process, I follow a regular schedule:

- Preventive Maintenance: Perform routine inspections, cleaning, and lubrication of equipment to prevent breakdowns.

- Calibration: Calibrate temperature sensors, pressure gauges, and other instruments according to the manufacturer’s recommendations to ensure accurate readings.

- Equipment Logs: Maintain detailed records of maintenance and calibration activities for future reference.

- Vendor Support: Consult with equipment vendors or service providers for specialized maintenance or calibration procedures.

7. What safety precautions do you take when operating the calcine furnace?

When operating the calcine furnace, I prioritize safety by adhering to these precautions:

- Personal Protective Equipment: Wear appropriate personal protective equipment, such as gloves, safety glasses, and fire-resistant clothing.

- Area Monitoring: Monitor the working area for potential hazards, such as gas leaks or spills.

- Safe Operating Procedures: Follow established safe operating procedures, including proper startup, shutdown, and emergency response protocols.

- Training and Authorization: Ensure that all operators are adequately trained and authorized to operate the furnace.

8. How do you optimize the calcination process to improve efficiency and reduce operating costs?

To optimize the calcination process and improve efficiency, I focus on these strategies:

- Fuel Efficiency: Optimize the fuel-air ratio and burner settings to minimize fuel consumption while maintaining the desired temperature.

- Feed Material Management: Ensure a consistent feed rate and uniform distribution of material to promote efficient combustion.

- Furnace Insulation: Maintain proper furnace insulation to minimize heat loss and improve energy efficiency.

- Process Monitoring: Continuously monitor process parameters and make adjustments as needed to maintain optimal operating conditions.

9. Explain the role of a calcine furnace in the production process of a specific industry?

Calcine furnaces play a crucial role in various industries, including:

- Cement Industry: Calcination of limestone to produce lime for cement manufacturing.

- Metallurgical Industry: Calcination of metal ores to remove impurities and prepare them for further processing.

- Chemical Industry: Calcination of raw materials to produce chemicals, such as soda ash or calcium oxide.

- Ceramic Industry: Calcination of clay minerals to produce ceramic materials.

10. How do you stay updated on advancements and best practices in calcine furnace technology?

To stay current on advancements and best practices in calcine furnace technology, I engage in the following activities:

- Industry Publications: Read technical journals, attend conferences, and participate in industry forums to learn about the latest developments.

- Equipment Vendor Updates: Consult with equipment manufacturers and service providers for information on new technologies and upgrades.

- Training and Workshops: Attend trainings and workshops to enhance my knowledge and skills in furnace operation and maintenance.

- Networking: Connect with other professionals in the field to exchange ideas and stay informed about industry best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Calcine Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Calcine Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Calcine Furnace Tenders play a pivotal role in industrial settings by operating and maintaining calcine furnaces to produce high-quality raw materials for further processing. Their key job responsibilities include:

1. Furnace Operation

Monitor and control furnace operations to ensure optimal temperatures, feed rates, and gas flows.

- Adjust furnace parameters based on process requirements.

- Inspect and maintain equipment for smooth operation.

2. Raw Material Handling

Manage the loading, unloading, and handling of raw materials and finished products.

- Ensure proper storage and handling of raw materials.

- Monitor material flow to avoid blockages and maintain production efficiency.

3. Quality Control

Monitor and maintain product quality by adhering to established standards.

- Conduct regular tests and inspections to ensure product specifications are met.

- Identify and rectify process deviations to improve product quality.

4. Maintenance and Troubleshooting

Perform preventive maintenance, repairs, and troubleshooting of equipment.

- Identify and diagnose equipment malfunctions.

- Carry out routine maintenance to minimize downtime and ensure equipment longevity.

Interview Tips

To ace an interview for a Calcine Furnace Tender position, candidates should:

1. Research and Knowledge

Thoroughly research the company, industry, and specific job requirements.

- Understand the calcination process and furnace operations.

- Be aware of safety regulations and quality control standards.

2. Highlight Relevant Experience

Emphasize any previous experience in furnace operation or raw material handling.

- Provide specific examples of responsibilities, accomplishments, and skills.

- Quantify results whenever possible to demonstrate impact.

3. Technical Skills

Showcase proficiency in relevant technical skills, such as:

- Temperature control and instrumentation

- Material handling and equipment operation

- Basic electrical and mechanical knowledge

4. Safety and Compliance

Demonstrate a strong understanding of safety protocols and adherence to industry regulations.

- Describe experience with hazard identification and risk assessments.

- Explain how you ensure compliance with environmental and safety standards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Calcine Furnace Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!