Are you gearing up for an interview for a Calciner Operator Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Calciner Operator Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

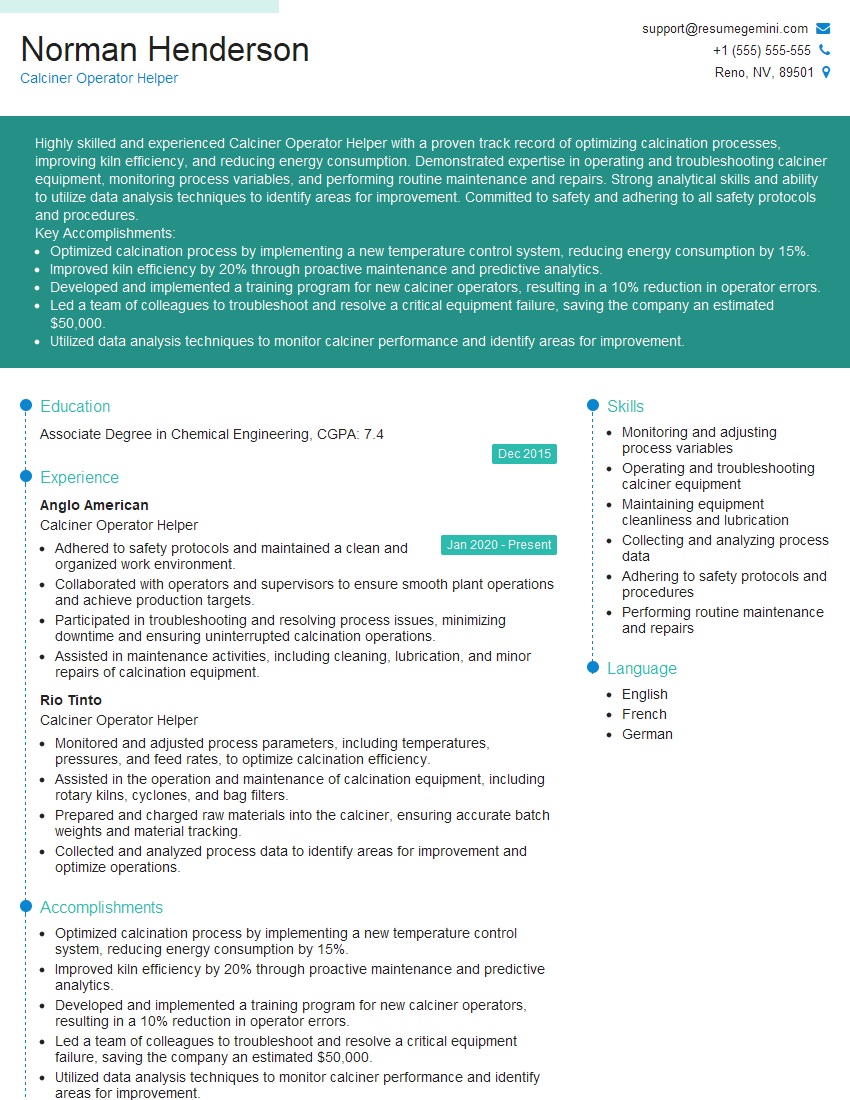

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Calciner Operator Helper

1. Explain the role of a Calciner Operator Helper?

A Calciner Operator Helper assists the Calciner Operator in the operation and maintenance of the calciner, which is a furnace used to heat and decompose raw materials. The helper’s responsibilities include:

- Monitoring and adjusting process controls to ensure optimal calcination conditions.

- Performing routine maintenance and repairs on the calciner and associated equipment.

- Assisting in the loading and unloading of raw materials and finished products.

- Collecting and analyzing samples to ensure product quality.

- Maintaining a clean and organized work area.

2. Describe the different types of calciners and their applications?

Rotary Calciners

- Used for continuous calcination of materials such as limestone, dolomite, and alumina.

- Consist of a rotating cylindrical vessel lined with refractory bricks.

Fluidized Bed Calciners

- Used for calcination of fine powders, such as fly ash and titanium dioxide.

- Consist of a bed of fluidized particles suspended by a stream of gas.

Multiple Hearth Calciners

- Used for calcination of materials that require precise temperature control.

- Consist of a series of superimposed hearths, each heated to a different temperature.

3. What are the key safety considerations when working with a calciner?

Key safety considerations when working with a calciner include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Being aware of the potential for high temperatures and hot surfaces.

- Knowing the location of emergency exits and fire extinguishers.

- Following proper lockout/tagout procedures when performing maintenance.

- Being aware of the potential for dust and other airborne contaminants.

4. What are the common problems that can occur during calcination and how do you troubleshoot them?

Common problems that can occur during calcination include:

- Insufficient calcination: This can be caused by factors such as incorrect temperature, insufficient residence time, or poor mixing.

- Over-calcination: This can be caused by factors such as excessive temperature or prolonged residence time.

- Caking or agglomeration: This can be caused by factors such as the presence of impurities or moisture in the feed material.

- Dusting: This can be caused by factors such as excessive fines in the feed material or poor gas flow.

Troubleshooting these problems involves identifying the underlying cause and taking corrective action, such as adjusting process parameters, modifying equipment, or changing the feed material.

5. How do you ensure the quality of the calcined product?

To ensure the quality of the calcined product, the following measures can be taken:

- Monitoring process parameters: Temperature, residence time, and gas flow are critical parameters that affect product quality.

- Sampling and testing: Regular sampling and testing of the calcined product can help identify any deviations from specifications.

- Calibration and maintenance: Ensuring that process controls and equipment are properly calibrated and maintained helps prevent errors and ensures consistent product quality.

- Training and supervision: Operators and helpers must be properly trained and supervised to ensure they understand the process and follow quality control procedures.

6. What maintenance tasks are typically performed on a calciner?

Typical maintenance tasks performed on a calciner include:

- Regular cleaning and inspection: This helps prevent buildup and ensures proper operation.

- Refractory repair: Refractory linings can deteriorate over time and need to be repaired or replaced.

- Mechanical maintenance: This includes tasks such as lubricating bearings, replacing belts, and repairing motors.

- Electrical maintenance: This includes tasks such as checking wiring, replacing fuses, and troubleshooting electrical faults.

7. How do you handle emergencies, such as a fire or equipment failure, while working with a calciner?

In the event of an emergency, it is important to remain calm and follow established safety procedures:

- Fire: Evacuate the area, activate the fire alarm, and use appropriate fire extinguishers.

- Equipment failure: Shut down the equipment, isolate it from power, and contact maintenance personnel.

- Medical emergency: Call for medical assistance and provide first aid as needed.

8. What are your strengths and weaknesses as a Calciner Operator Helper?

Strengths:

- Experience in operating and maintaining calciners.

- Strong understanding of calcination process and quality control.

- Ability to work independently and as part of a team.

- Excellent communication and interpersonal skills.

Weaknesses:

- Limited experience with certain types of calciners.

- Working in high-temperature environments can be physically demanding.

- Continuous monitoring and adjustment of process parameters can require attention to detail.

9. Why are you interested in this Calciner Operator Helper position?

I am interested in this Calciner Operator Helper position because it aligns with my skills and experience in the calcination industry. I am eager to contribute to the team and learn from experienced professionals. Additionally, I am passionate about ensuring product quality and maintaining a safe and efficient work environment.

10. Where do you see yourself in five years?

In five years, I aspire to have gained significant experience and knowledge as a Calciner Operator Helper. I am confident that my commitment to safety, quality, and continuous improvement will enable me to grow within the company and potentially advance to a Calciner Operator role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Calciner Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Calciner Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Calciner Operator Helper supports the Calciner Operator in the day-to-day operations of a calciner unit, which is used to heat and decompose materials to produce various products. Key responsibilities include:

1. Monitoring and Controlling Equipment

Monitor and control various equipment within the calciner unit, including conveyors, feeders, blowers, and temperature controls.

- Ensure that equipment operates safely and efficiently within established parameters.

- Calibrate and maintain equipment to ensure accurate readings and performance.

2. Quality Control

Conduct routine inspections of raw materials and finished products to ensure they meet specifications.

- Collect and analyze samples to monitor product quality.

- Identify and report any deviations from standards.

3. Safety

Maintain a safe work environment by adhering to established safety protocols.

- Wear proper personal protective equipment (PPE).

- Follow lockout/tagout procedures when working on equipment.

- Report any safety hazards or incidents.

4. Training and Support

Assist in training and supporting other operators in the calciner unit.

- Provide guidance and instruction on equipment operation and procedures.

- Cover for the Calciner Operator during absences or emergencies.

Interview Tips

To succeed in a Calciner Operator Helper interview, it’s crucial to prepare thoroughly and demonstrate your knowledge and skills:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and values.

- Understand the specific responsibilities and requirements of the Calciner Operator Helper role.

- Research common calciner unit processes and equipment.

2. Highlight Relevant Experience

Emphasize your experience in monitoring and controlling industrial equipment, conducting quality control inspections, and adhering to safety regulations.

- Provide specific examples of your contributions and accomplishments.

- Quantify your results whenever possible.

3. Demonstrate Problem-Solving Abilities

Share examples of how you have solved problems or handled unexpected situations in a work environment.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Emphasize your ability to think critically and find effective solutions.

4. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and motivations.

- Practice your answers to questions such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

- Seek feedback from a mentor or career counselor to refine your answers.

Next Step:

Now that you’re armed with the knowledge of Calciner Operator Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Calciner Operator Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini