Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Calender Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Calender Machine Operator so you can tailor your answers to impress potential employers.

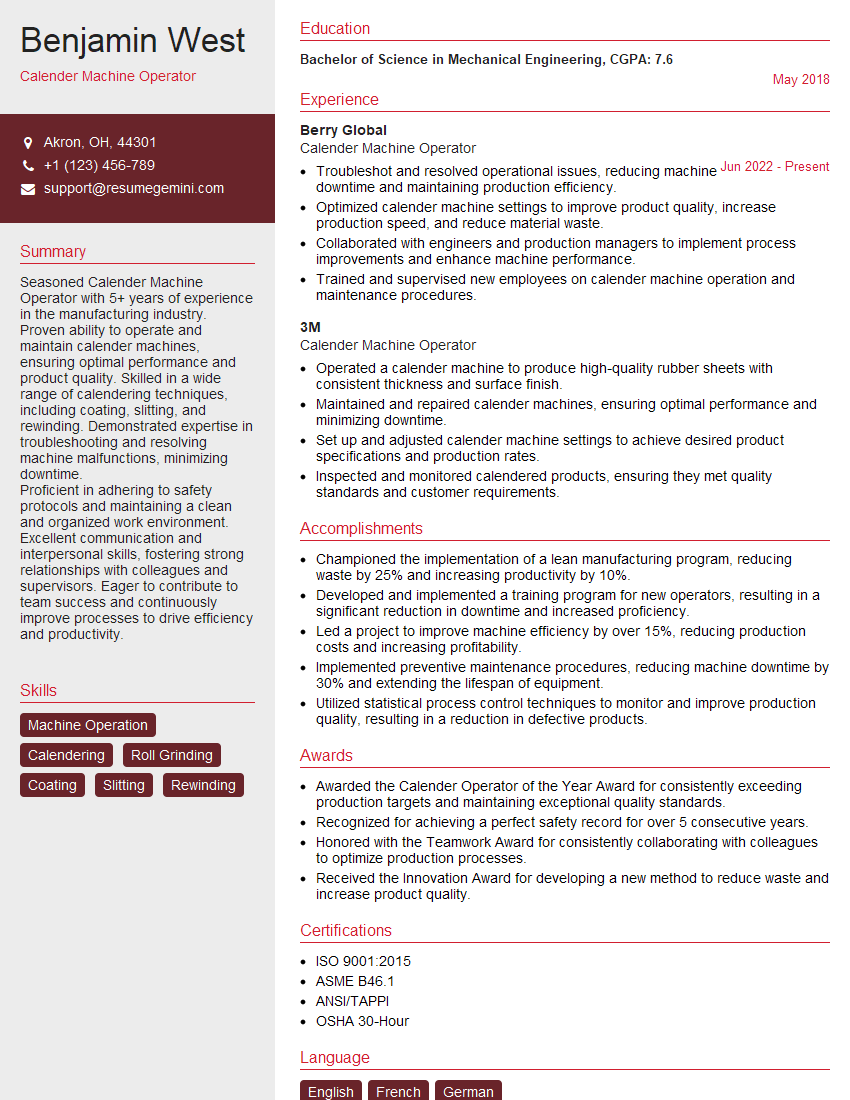

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Calender Machine Operator

1. Describe the key aspects of the calendering process and the role of the Calender Machine Operator in it?

The calendering process involves passing the material through a series of rollers under heat and pressure to achieve desired properties. The Calender Machine Operator is responsible for:

- Preparing the machine and materials for calendering

- Adjusting machine settings and ensuring optimal operating conditions

- Monitoring the calendering process and making adjustments as needed

- Ensuring product quality and meeting specifications

- Maintaining and troubleshooting the calender machine

2. Explain the different types of calendering machines and their applications?

Types of Calendering Machines:

- Roll-type calenders: Used for thin materials such as paper, textiles, and films

- Platen-type calenders: Used for thicker materials such as rubber and plastics

- Laminating calenders: Used to bond multiple layers of material together

- Embossing calenders: Used to create patterns or textures on the surface of the material

Applications:

- Improving surface finish and smoothness

- Controlling thickness and dimensions

- Modifying physical properties such as strength, stiffness, and flexibility

- Applying patterns or textures

- Bonding multiple materials

3. Describe the critical factors that affect the quality of the calendered product?

Factors affecting calendered product quality include:

- Material properties and preparation

- Calender machine settings (temperature, pressure, speed)

- Roll alignment and condition

- Proper lubrication and maintenance

- Operator skill and experience

- Environmental conditions (temperature, humidity)

4. How do you ensure the accuracy and precision of the calendering process?

To ensure accuracy and precision in the calendering process, I follow these steps:

- Calibrating the machine regularly according to manufacturer’s specifications

- Using precision measuring tools and gauges

- Monitoring process variables such as temperature, pressure, and speed

- Performing regular inspections and maintenance

- Following established quality control procedures

5. What are the common problems encountered during calendering and how do you troubleshoot them?

Common Problems:

- Wrinkles or creases

- Uneven calendering

- Surface defects (scratches, dents)

- Dimensional inaccuracies

- Machine malfunctions

Troubleshooting:

- Check material preparation and settings

- Inspect rolls and bearings for damage

- Adjust machine parameters (speed, pressure, temperature)

- Lubricate and clean the machine

- Consult with technical support or maintenance personnel

6. How do you maintain and service the calender machine to ensure optimal performance?

To maintain and service the calender machine for optimal performance, I perform the following tasks:

- Regular lubrication and cleaning

- Inspection of rolls and bearings for wear or damage

- Alignment and calibration of components

- Replacement of worn or damaged parts

- Troubleshooting and repair of machine malfunctions

- Following manufacturer’s maintenance schedule

7. How do you handle and store calendered materials to prevent damage?

To handle and store calendered materials to prevent damage, I follow these procedures:

- Carefully remove calendered materials from the machine

- Place them on a flat surface or in a designated storage area

- Ensure proper ventilation to avoid moisture buildup

- Protect materials from excessive heat, cold, or direct sunlight

- Use appropriate packaging and labeling for transportation and storage

8. What safety precautions should be taken when operating a calender machine?

Safety precautions for operating a calender machine include:

- Wear appropriate protective gear (gloves, safety glasses, hearing protection)

- Never put hands or fingers between rolls

- Keep the work area clean and free of debris

- Follow established lockout/tagout procedures

- Be aware of potential hazards such as moving parts, high temperatures, and electrical equipment

9. How do you ensure the efficient operation of the calendering line and minimize downtime?

To ensure efficient operation and minimize downtime, I:

- Plan and schedule calendering runs to optimize production

- Monitor the calendering process and make adjustments as needed

- Perform routine maintenance and inspections

- Troubleshoot and resolve issues promptly

- Communicate effectively with colleagues and management

10. Describe your experience in working with different materials during calendering operations. How did you adapt to the unique characteristics of each material?

I have experience calendering a wide range of materials, including:

- Paper

- Textiles

- Plastics

- Rubber

When working with different materials, I adjust the calendering process according to their unique properties. For example, with delicate materials like paper, I use lower pressure and higher speed to avoid tearing. For thicker materials like rubber, I use higher pressure and lower speed to achieve the desired level of compression.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Calender Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Calender Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

This job requires a highly skilled and experienced individual to operate a Calender Machine, which is used in various industries, such as papermaking, textile manufacturing, and plastics processing, to improve the surface finish, impart desired properties, and control thickness of materials.

1. Operating the Calender Machine

The operator is responsible for setting up, operating, maintaining, and troubleshooting the Calender Machine.

- Set up the machine according to job specifications, including adjusting roll pressure, temperature, and speed.

- Monitor the machine during operation and adjust settings as needed to ensure optimal performance.

- Troubleshoot and resolve any mechanical or operational issues with the machine.

2. Material Handling and Inspection

The operator is also responsible for handling and inspecting the materials that are being processed by the Calender Machine.

- Load and unload materials onto the machine, ensuring proper alignment and tension.

- Inspect materials before and after processing to ensure quality standards are met.

- Make adjustments to the machine’s settings based on the material’s characteristics.

3. Quality Control and Maintenance

The operator plays a crucial role in maintaining the quality of the finished products and ensuring the smooth operation of the Calender Machine.

- Monitor the quality of the processed materials and make adjustments to the machine’s settings as needed.

- Perform routine maintenance tasks on the machine, including cleaning, lubricating, and replacing worn parts.

- Follow safety protocols and maintain a clean and organized work area.

4. Collaboration and Communication

The operator works closely with other team members and communicates effectively to ensure the smooth running of the production process.

- Communicate with supervisors, maintenance personnel, and other operators to coordinate work and resolve issues.

- Provide regular updates on the machine’s performance and any potential problems.

- Collaborate with quality control personnel to ensure that the finished products meet specifications.

Interview Preparation Tips

To prepare effectively for a Calender Machine Operator interview, consider implementing the following comprehensive strategies.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry standing. Research the specific industry in which the company operates, as this knowledge will demonstrate your interest and engagement.

2. Study Job Description and Qualifications

Thoroughly review the job description to grasp the specific responsibilities and qualifications required for the role. Identify key skills and experiences that align with your background and highlight them in your resume and during the interview.

3. Practice Common Interview Questions

Prepare for common interview questions by anticipating potential inquiries about your technical skills, experience with Calender Machines, and problem-solving abilities. Practice answering these questions concisely and confidently.

4. Prepare Industry-Specific Questions

Consider preparing industry-specific questions to demonstrate your knowledge and enthusiasm. This could involve inquiring about the company’s approach to quality control, their experience with specific materials or processes, or their plans for future technological advancements.

5. Showcase Your Skills and Experience

Highlight your relevant skills and experience throughout the interview. Quantify your accomplishments whenever possible, providing specific examples that demonstrate your proficiency in operating and maintaining Calender Machines.

6. Emphasize Safety and Attention to Detail

Emphasize your commitment to safety and attention to detail. These qualities are crucial for Calender Machine Operators, as ensuring the safety of both the machine and the materials is paramount.

7. Prepare Questions for the Interviewer

At the end of the interview, ask thoughtful questions that show your interest and engagement. This could include inquiring about the company’s training programs, opportunities for career growth, or their vision for the future.

8. Dress Professionally and Be Punctual

First impressions matter. Dress professionally and arrive for the interview on time. This demonstrates respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Calender Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!