Are you gearing up for a career in Calender Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Calender Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

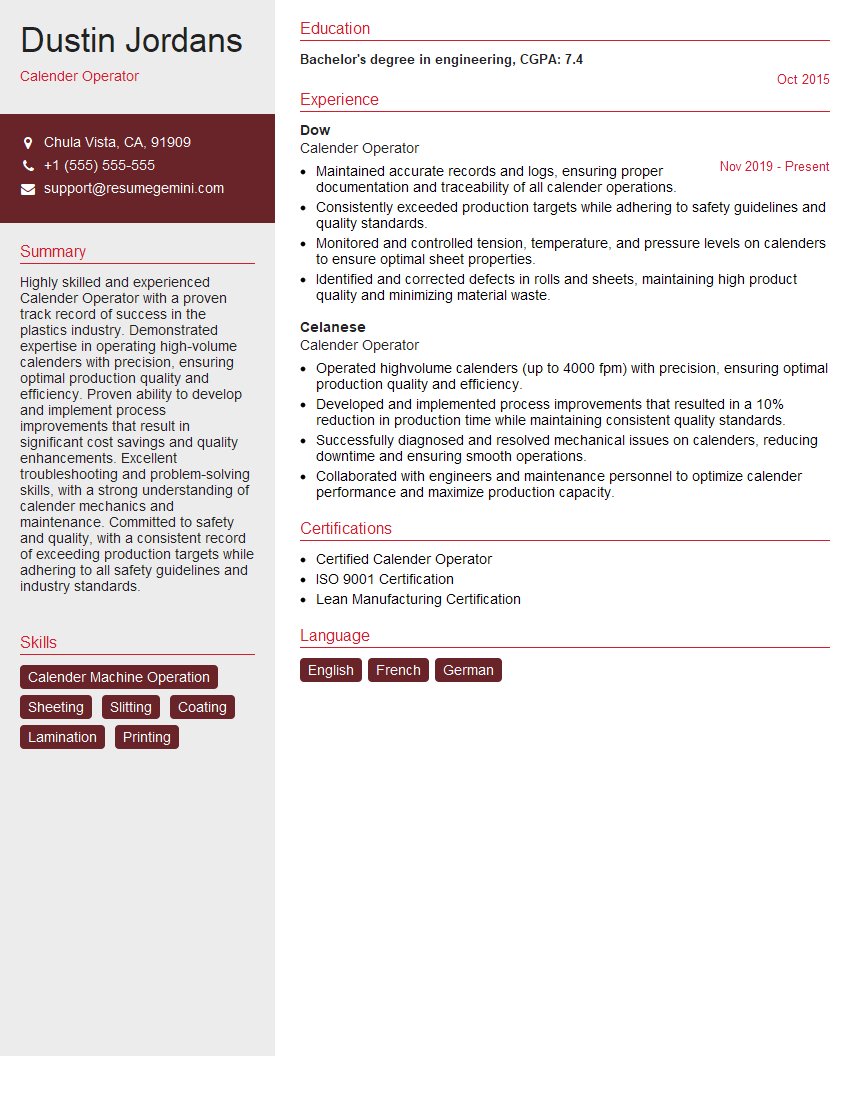

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Calender Operator

1. Describe the process of loading and aligning reels in a calendar machine?

– Check the reel size and specifications to ensure they meet the machine’s requirements. – Inspect the reel for any damage or imperfections. – Mount the reel on the reel stand and align it with the machine’s center line. – Thread the web through the machine’s tension control system. – Adjust the tension to ensure proper web tension and prevent web breaks. – Perform splices or welds to join the new reel to the outgoing web.

2. Explain the importance of roll grinding in calendaring?

- Restores the roll’s original shape and surface finish

- Removes wear and tear from the roll surface

- Improves the roll’s surface hardness and durability

- Reduces friction and heat generation during calendaring

- Enhances product quality and uniformity

- Reduces waste and rejects due to surface imperfections

- Increases machine efficiency and productivity

- Extends the lifespan of the calender rolls

3. What are the common defects that can occur during calendaring and how do you correct them?

- Blistering: Caused by air or moisture trapped in the web; correct by adjusting the temperature and pressure settings.

- Wrinkling: Caused by uneven web tension; correct by adjusting the web tension control system.

- Over-calendering: Caused by excessive pressure or temperature; correct by reducing the pressure or temperature.

- Scratching: Caused by dirt or debris on the rolls; correct by cleaning the rolls and inspecting the web for foreign objects.

- Adhesion: Caused by improper release agents or web contamination; correct by applying suitable release agents and cleaning the web.

4. How do you maintain the accuracy and calibration of calender equipment?

- Regularly inspect and clean all equipment components.

- Calibrate the pressure gauges and tension control systems.

- Check the roll alignment and adjust as necessary.

- Monitor the temperature and humidity levels in the calendering environment.

- Use calibrated measuring devices to ensure accurate product dimensions.

5. What safety precautions should be taken during calendering operations?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Keep hands and body parts away from moving machinery.

- Be aware of pinch points and other potential hazards.

- Follow lockout/tagout procedures when servicing or repairing equipment.

- Report any unsafe conditions or equipment malfunctions immediately.

6. Explain the different types of calenders and their specific applications.

- Two-roll calender: Used for simple operations like glossing and imparting a smooth finish.

- Three-roll calender: Used for more complex operations like embossing, coating, and laminating.

- Four-roll calender: Used for high-quality finishing and specialized applications.

- Inverted “L” calender: Used for coating and laminating with sensitive materials.

- Stack calender: Used for calendering multiple layers of materials simultaneously.

7. Describe the factors that influence the selection of calendering rolls.

- Material: Rubber, steel, or composite materials with specific hardness and elasticity.

- Surface finish: Smooth, textured, or patterned depending on the desired product finish.

- Diameter: Determines the thickness reduction and pressure applied to the web.

- Crown: A slight curvature that prevents edge markings on the web.

- Temperature control: Heated or cooled rolls for specific applications.

8. Explain how calendering affects the properties of the processed material.

- Thickness reduction: Calendering reduces the material’s thickness, improving its uniformity and dimensional stability.

- Surface finish: Calendering creates a smooth or textured surface, enhancing its appearance and functionality.

- Optic properties: Calendering can enhance the material’s gloss, opacity, and transparency.

- Mechanical properties: Calendering can improve the material’s tensile strength, tear resistance, and flexibility.

- Electrical properties: Calendering can alter the material’s electrical insulation properties.

9. Discuss the energy efficiency considerations in calendering operations.

- Roll heating/cooling: Optimizing temperature control to minimize energy consumption.

- Friction reduction: Using release agents and anti-friction bearings to reduce friction and power consumption.

- Variable speed drives: Adjusting roll speeds to match production requirements and save energy.

- Load monitoring: Calendering only when necessary to avoid unnecessary energy usage.

- Equipment maintenance: Regular maintenance to prevent equipment inefficiencies and energy losses.

10. What are the challenges and troubleshooting techniques in calendering operations?

- Web breaks: Monitor web tension, adjust roll settings, and inspect web condition.

- Surface defects: Inspect rolls for damage, adjust temperature and pressure, optimize release agents.

- Dimensional variations: Correct roll alignment, calibrate pressure gauges, and monitor web tension.

- Equipment malfunctions: Conduct regular maintenance, inspect components, and follow troubleshooting protocols.

- Visual inspection: Check for visible defects on web, rolls, and equipment.

- Data analysis: Monitor pressure, temperature, and tension data to identify trends and anomalies.

- Process adjustment: Fine-tune process parameters to resolve specific issues.

- Equipment repair: Replace or repair faulty components as necessary.

- Consultation with experts: Seek guidance from technical specialists or equipment manufacturers for complex troubleshooting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Calender Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Calender Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Calender Operators are responsible for the smooth and efficient operation of calendering machines, which are used to shape and finish rubber and plastic materials.

1. Machine Operation

Calender Operators are responsible for setting up, operating, and maintaining calendering machines according to specifications.

- Loading and unloading raw materials

- Adjusting machine settings for different materials and products

- Monitoring machine performance and making adjustments as needed

- Troubleshooting and resolving machine problems

2. Product Quality Control

Calender Operators are responsible for ensuring the quality of the products produced by calendering machines.

- Inspecting raw materials and finished products for defects

- Maintaining quality control records

- Reporting any quality issues to supervisors

3. Safety and Maintenance

Calender Operators are responsible for maintaining a safe and clean work environment.

- Following safety procedures

- Performing routine maintenance on calendering machines

- Reporting any safety or maintenance issues to supervisors

- Keeping work area clean and organized

4. Teamwork and Communication

Calender Operators work as part of a team and communicate with other employees, including supervisors, engineers, and quality control personnel.

- Collaborating with others to solve problems

- Communicating with supervisors about machine performance and product quality

- Participating in training and development programs

Interview Tips

To ace an interview for a Calender Operator position, it’s important to prepare thoroughly and highlight your relevant skills and experience.

1. Research the Company and Position

Research the company’s history, products, and culture. Understanding the company’s business will help you better tailor your answers and show that you’re genuinely interested in the position.

- Visit the company’s website and social media pages

- Read industry news and articles about the company

- Review the job description carefully and identify the key skills and responsibilities

2. Prepare Your Answers

Take time to prepare answers to common interview questions, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Describe your experience with calendering machines.

- How do you ensure product quality?

3. Practice Your Delivery

Practice your answers out loud to ensure that you are clear and articulate. You can also ask a friend or family member to conduct a mock interview with you.

- Speak clearly and confidently

- Use specific examples to illustrate your skills and experience

- Be enthusiastic and positive

4. Dress Professionally

Dress professionally for your interview. This shows that you respect the company and the position.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Avoid wearing strong perfumes or colognes

5. Arrive on Time

Punctuality is important for any interview. Arrive on time or even a few minutes early to show that you are respectful of the interviewer’s time.

- Plan your route in advance

- Allow for extra time in case of traffic or other delays

- Call or email the interviewer if you are running late

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Calender Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!