Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Calibration Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

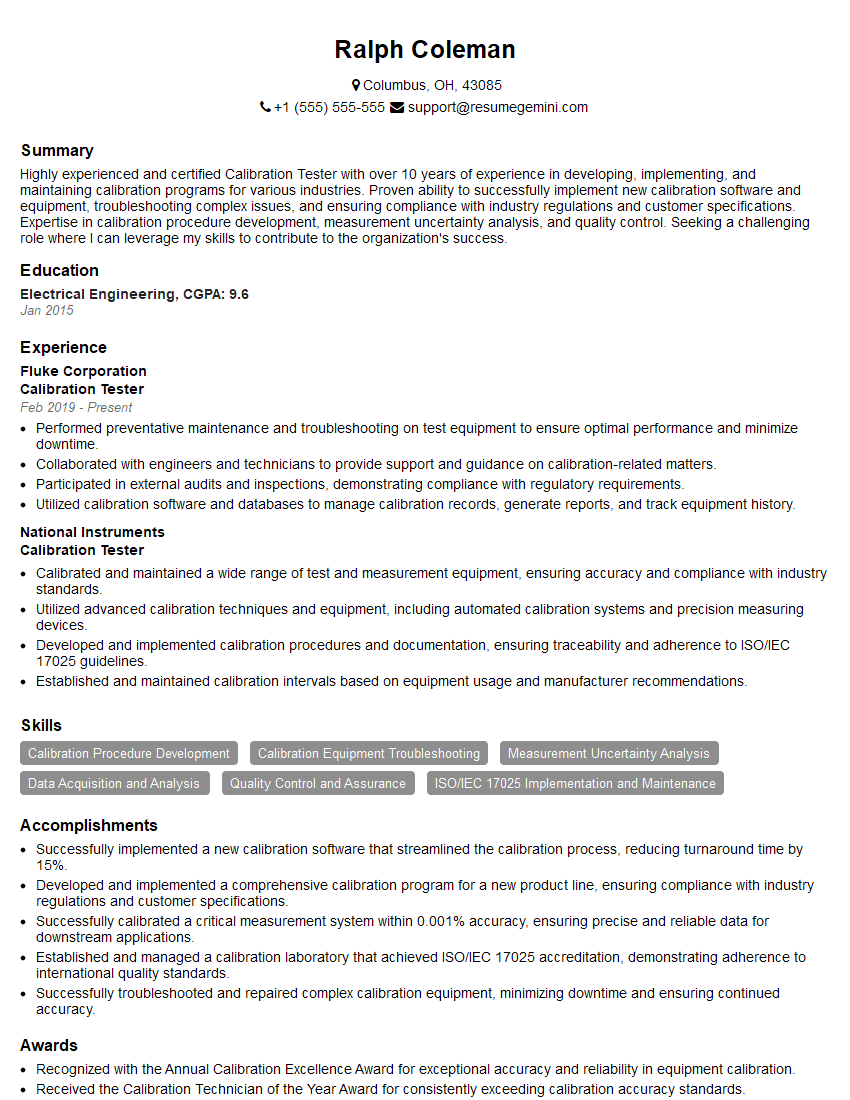

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Calibration Tester

1. What are the different types of calibration standards used in the calibration process?

There are several types of calibration standards used in the calibration process, including:

- Primary standards: These are the highest level of calibration standards and are traceable to national or international standards organizations.

- Secondary standards: These are calibrated against primary standards and are used to calibrate other instruments.

- Working standards: These are used to calibrate instruments that are used in the production process.

- Reference standards: These are used to verify the accuracy of other calibration standards.

2. What are the different methods of calibration?

There are several different methods of calibration, including:

Static calibration

- This method involves comparing the output of the instrument being calibrated to a known standard.

- The instrument is set to a specific input value and the output is measured.

- The output is then compared to the known standard and any necessary adjustments are made.

Dynamic calibration

- This method involves applying a known input signal to the instrument being calibrated and measuring the output.

- The input signal is varied over a range of values and the output is measured at each value.

- The output is then compared to the known input signal and any necessary adjustments are made.

Closed-loop calibration

- This method involves using a feedback loop to control the input signal to the instrument being calibrated.

- The output of the instrument is measured and compared to a known standard.

- The feedback loop is then used to adjust the input signal until the output matches the known standard.

3. What are the factors that can affect the accuracy of calibration?

Several factors can affect the accuracy of calibration, including:

- The quality of the calibration standards: The accuracy of the calibration standards is directly proportional to the accuracy of the calibration.

- The condition of the instrument being calibrated: The condition of the instrument can affect the accuracy of the calibration.

- The environment in which the calibration is performed: The environment can affect the accuracy of the calibration, such as temperature, humidity, and vibration.

- The skill of the calibration technician: The skill of the calibration technician can affect the accuracy of the calibration.

4. What are the different types of calibration reports?

There are several different types of calibration reports, including:

- As-found reports: These reports document the condition of the instrument before calibration.

- As-left reports: These reports document the condition of the instrument after calibration.

- Traceable calibration reports: These reports provide a complete history of the calibration of the instrument, including the calibration standards used and the traceability of the standards.

5. What are the benefits of using a calibration management system?

Using a calibration management system can provide several benefits, including:

- Improved accuracy and reliability of measurements: A calibration management system can help to ensure that instruments are calibrated regularly and accurately.

- Reduced downtime: A calibration management system can help to reduce downtime by identifying instruments that need calibration and scheduling calibration appointments.

- Improved compliance with regulations: A calibration management system can help to ensure that instruments are calibrated according to regulatory requirements.

6. What are the different types of calibration equipment?

There are several different types of calibration equipment, including:

- Electrical calibrators: These devices are used to calibrate electrical instruments, such as voltmeters, ammeters, and oscilloscopes.

- Mechanical calibrators: These devices are used to calibrate mechanical instruments, such as pressure gauges, torque wrenches, and flow meters.

- Dimensional calibrators: These devices are used to calibrate dimensional instruments, such as micrometers, calipers, and rulers.

- Temperature calibrators: These devices are used to calibrate temperature instruments, such as thermometers and thermocouples.

7. What are the different types of calibration techniques?

There are several different types of calibration techniques, including:

- Static calibration: This technique involves comparing the output of the instrument being calibrated to a known standard.

- Dynamic calibration: This technique involves applying a known input signal to the instrument being calibrated and measuring the output.

- Closed-loop calibration: This technique involves using a feedback loop to control the input signal to the instrument being calibrated.

- Automated calibration: This technique involves using a computer to control the calibration process.

8. What are the different types of calibration standards?

There are several different types of calibration standards, including:

- Primary standards: These are the highest level of calibration standards and are traceable to national or international standards organizations.

- Secondary standards: These are calibrated against primary standards and are used to calibrate other instruments.

- Working standards: These are used to calibrate instruments that are used in the production process.

- Reference standards: These are used to verify the accuracy of other calibration standards.

9. What are the different types of calibration procedures?

There are several different types of calibration procedures, including:

- Written procedures: These procedures are written down and provide step-by-step instructions on how to perform the calibration.

- Verbal procedures: These procedures are not written down but are communicated verbally by a qualified technician.

- Automated procedures: These procedures are performed by a computer using a software program.

10. What are the different types of calibration reports?

There are several different types of calibration reports, including:

- As-found reports: These reports document the condition of the instrument before calibration.

- As-left reports: These reports document the condition of the instrument after calibration.

- Traceable calibration reports: These reports provide a complete history of the calibration of the instrument, including the calibration standards used and the traceability of the standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Calibration Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Calibration Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Calibration Testers are responsible for ensuring the accuracy and precision of measuring instruments used in various industries.

1. Calibration and Testing

Perform scheduled and unscheduled calibration and testing of measuring instruments as per established procedures.

- Use standard equipment to verify the accuracy and traceability of instruments.

- Conduct functional checks and perform necessary adjustments to ensure instrument performance meets specifications.

2. Documentation and Record Keeping

Document calibration results, including observed deviations and corrective actions taken.

- Maintain calibration records and ensure their accessibility for audit purposes.

- Prepare calibration certificates and reports for customers.

3. Equipment Maintenance and Repair

Perform basic maintenance and repairs on calibration equipment and measuring instruments.

- Troubleshoot malfunctions, identify faulty components, and replace or repair them.

- Maintain a clean and organized work area to ensure optimal equipment performance.

4. Quality Control and Assurance

Adhere to industry standards and regulations related to calibration and testing.

- Ensure that calibration equipment is regularly calibrated and traceable to national or international standards.

- Participate in quality improvement initiatives and provide feedback on calibration processes.

Interview Tips

Preparing for a Calibration Tester interview requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company’s mission, values, and the specific requirements of the Calibration Tester role.

- Visit the company website, LinkedIn page, and industry publications.

- Identify the key responsibilities and qualifications listed in the job description.

2. Highlight Your Technical Skills

Emphasize your experience and expertise in calibration techniques, instrument testing, and quality control.

- Quantify your accomplishments with specific examples and metrics.

- Discuss your knowledge of calibration standards and regulations.

3. Showcase Your Troubleshooting Abilities

Calibration Testers are often required to troubleshoot and repair equipment. Highlight your analytical and problem-solving skills.

- Provide examples of how you identified and resolved instrument malfunctions.

- Explain your systematic approach to troubleshooting.

4. Emphasize Your Attention to Detail

Calibration and testing require meticulous attention to detail. Showcase your ability to work accurately and efficiently.

- Discuss your experience in maintaining precise records and adhering to standard operating procedures.

- Highlight your focus on quality and your commitment to ensuring accurate measurements.

5. Practice Common Interview Questions

Prepare for common interview questions related to calibration techniques, equipment maintenance, and quality assurance.

- Practice answering questions about your experience, skills, and knowledge.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Calibration Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!