Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Camera Machinist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

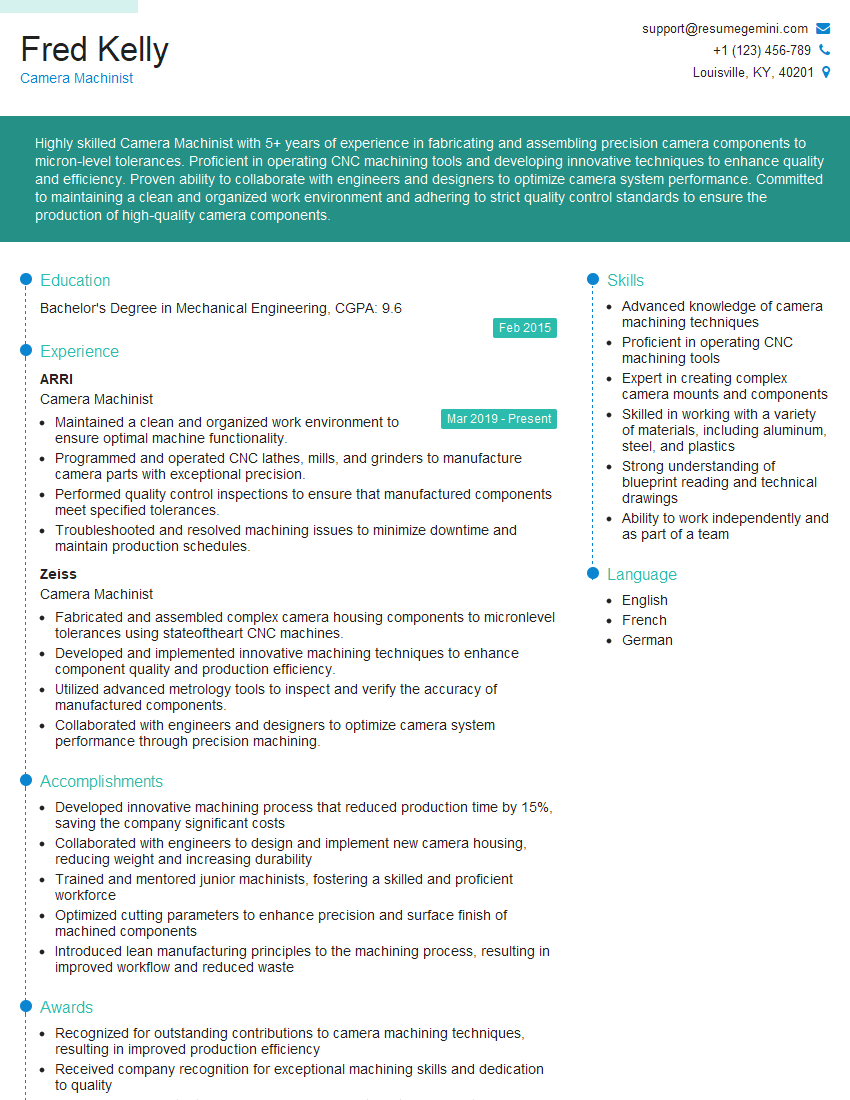

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Camera Machinist

1. Explain the process of setting up and calibrating a camera for machining operations?

Answer:

- Mount the camera on a stable platform and align it with the workpiece.

- Use a lens with the appropriate focal length for the desired field of view.

- Calibrate the camera using a reference object with known dimensions.

- Adjust the camera’s exposure and white balance settings to optimize image quality.

- Verify the camera’s accuracy by taking test measurements.

2. Describe the different types of camera lenses and their applications in machining operations?

Answer:

Types of Camera Lenses:

- Fixed Focal Length Lenses: Provide a constant field of view and are used for applications requiring precise measurements.

- Zoom Lenses: Allow for variable focal lengths, making them versatile for different field of views and working distances.

- Telecentric Lenses: Minimize perspective distortion, resulting in accurate measurements regardless of the camera’s distance from the workpiece.

Applications:

- Fixed Focal Length Lenses: Ideal for measuring small features and calibrations.

- Zoom Lenses: Suitable for inspecting large workpieces and capturing images from various angles.

- Telecentric Lenses: Used in precision measurements and applications where perspective distortion is critical.

3. How do you ensure the accuracy of camera measurements in machining operations?

Answer:

- Use calibrated cameras with traceable calibration certificates.

- Verify the accuracy of the reference object used for calibration.

- Consider the effects of lighting, temperature, and vibration on camera accuracy.

- Use software algorithms to compensate for lens distortion and other image imperfections.

- Regularly recalibrate cameras to maintain their accuracy over time.

4. Describe the different software programs used in camera machining and their capabilities?

Answer:

- Camera Control Software: Controls the camera’s settings, captures images, and saves them in various formats.

- Measurement Software: Analyzes images to extract measurements, such as dimensions, angles, and surface roughness.

- Image Processing Software: Enhances images to improve their quality and remove noise or unwanted elements.

- Machine Integration Software: Interfaces the camera system with CNC machines for automated measurement and control.

5. Explain the importance of using high-resolution cameras in machining operations?

Answer:

- Increased image detail allows for more precise measurements.

- Enables the detection of smaller features and defects.

- Improves the accuracy of image processing algorithms.

- Facilitates the capture of high-quality images for documentation and quality control.

6. Discuss the challenges and limitations of using camera machining systems?

Answer:

Challenges:

- Lighting conditions can affect image quality and measurement accuracy.

- Vibration and movement can cause image blur and measurement errors.

- Occlusions and shadows can hinder the measurement of certain features.

Limitations:

- Limited depth of field, which may require multiple images for accurate measurements.

- Not suitable for measuring complex geometries or hidden surfaces.

7. Describe the role of lighting in camera machining and how different types of lighting can affect the quality of measurements?

Answer:

- Uniform Lighting: Provides consistent illumination, reducing image noise and improving measurement accuracy.

- Diffuse Lighting: Minimizes shadows and reflections, resulting in more detailed images.

- Structured Lighting: Projects patterns of light onto the workpiece to enhance surface texture analysis and defect detection.

- Backlighting: Highlights surface features and helps in detecting cracks or defects.

8. How do you maintain and troubleshoot camera machining systems to ensure optimal performance?

Answer:

Maintenance:

- Clean lenses and cameras regularly to prevent dust and debris accumulation.

- Calibrate cameras periodically to maintain measurement accuracy.

- Inspect lighting equipment and ensure proper operation.

Troubleshooting:

- Blurry Images: Check for proper focus, lens cleanliness, and vibration isolation.

- Inaccurate Measurements: Verify camera calibration, lighting conditions, and reference object accuracy.

- Image Artifacts: Investigate for electrical noise, image processing errors, or software issues.

9. Describe the applications of camera machining in various industries?

Answer:

- Automotive: Inspecting parts, measuring dimensions, and identifying defects.

- Aerospace: Analyzing surface finishes, checking for cracks, and verifying component alignment.

- Medical: Measuring implants, surgical tools, and prosthetics.

- Electronics: Inspecting printed circuit boards, semiconductor wafers, and connectors.

- Manufacturing: Quality control, process monitoring, and reverse engineering.

10. What are the emerging trends and advancements in camera machining technology?

Answer:

- Increased Resolution and Sensitivity: Cameras with higher pixel counts and enhanced low-light capabilities.

- Artificial Intelligence (AI): Integration of AI algorithms to automate measurements and defect detection.

- Non-Contact Measurement: Development of cameras capable of measuring complex shapes and features without direct contact.

- Real-Time Processing: Camera systems with built-in processing capabilities for faster analysis and decision-making.

- Cloud Integration: Connectivity with cloud platforms for remote monitoring and data storage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Camera Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Camera Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Camera machinists play a crucial role in the manufacturing process by operating sophisticated machinery and equipment to produce high-precision camera components. Their responsibilities encompass a range of tasks, including:

1. Precision Machining

Camera machinists are responsible for operating CNC (Computer Numerical Control) milling and turning machines to create intricate parts with submicron tolerances.

- Setting up and optimizing CNC machines based on specifications.

- Interpreting technical drawings and selecting appropriate cutting tools.

2. Quality Control

Ensuring the quality of camera components is paramount. Camera machinists conduct rigorous inspections and measurements using CMMs (Coordinate Measuring Machines) and other precision instruments.

- Inspecting parts for dimensional accuracy, surface finish, and other critical parameters.

- Identifying and correcting any non-conformities to ensure that components meet specifications.

3. Troubleshooting

When technical glitches occur, camera machinists troubleshoot and resolve issues efficiently.

- Diagnosing machine malfunctions and determining root causes.

- Performing repairs and adjustments to restore optimal machine performance.

4. Maintenance

To ensure precision and longevity, camera machinists perform regular maintenance on equipment.

- Cleaning and lubricating machines to prevent wear and tear.

- Calibrating equipment to maintain accuracy and precision.

Interview Tips

To ace an interview for a camera machinist position, it’s essential to prepare thoroughly and showcase your skills and experience effectively. Here are some tips and hacks to help you succeed:

1. Research the Company and Role

Thoroughly research the company and the specific camera machinist role you’re applying for. This will help you understand the company’s culture, industry, and the responsibilities associated with the position.

- Visit the company’s website and social media pages to learn about their products, services, and values.

- Review the job description carefully and identify the key skills and qualifications required.

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to highlight your relevant skills and experience. Quantify your accomplishments whenever possible to demonstrate your impact on previous roles.

- For example, instead of stating “operated CNC machines,” you could say, “Operated CNC milling machines to produce camera components with an average tolerance of 0.0005 inches.”

- Use specific examples from your work history to demonstrate your proficiency in precision machining, quality control, troubleshooting, and maintenance.

3. Prepare for Technical Questions

Expect to be asked technical questions about camera machining, such as:

- What is your experience with CNC milling and turning machines?

- How do you ensure the precision and quality of camera components?

- What troubleshooting techniques have you used to resolve machine malfunctions?

4. Practice Your Answers

Practice answering common interview questions aloud or with a mock interviewer. This will help you articulate your thoughts clearly and confidently.

- Prepare brief and concise answers that highlight your skills and experience.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest and engagement. This is an excellent opportunity to learn more about the company and the role.

- For example, you could ask about the company’s future projects, the opportunities for professional development, or the company’s commitment to quality.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Camera Machinist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Camera Machinist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.