Are you gearing up for a career in Can Capper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Can Capper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

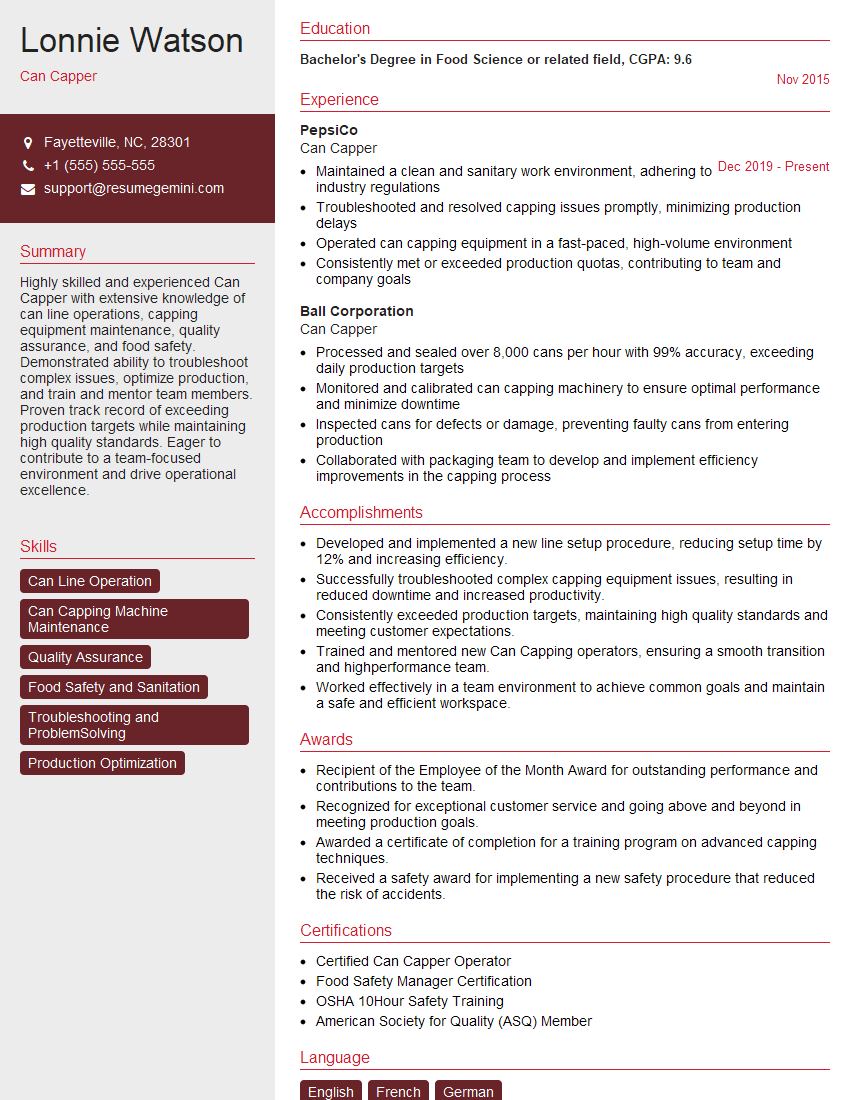

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Capper

1. Tell me about your experience in can capping?

In my previous role at [Company Name], I was responsible for overseeing the entire can capping process, ensuring the production of high-quality, leak-proof cans. I have extensive knowledge of all aspects of can capping, including machine operation, maintenance, and troubleshooting.

2. What are the different types of can cappers and their advantages and disadvantages?

Rotary Can Cappers

- Advantages: High speed, suitable for large production volumes, automated process.

- Disadvantages: Complex and expensive, require skilled operators.

Inline Can Cappers

- Advantages: Compact and space-efficient, suitable for smaller production volumes.

- Disadvantages: Slower speed, require more manual labor.

3. How do you ensure the proper seaming of cans?

Ensuring proper seaming is crucial for maintaining product quality and preventing leakage. I follow a meticulous process that includes:

- Inspecting cans for any defects or damage.

- Adjusting the seaming machine’s settings to match the can size and type.

- Monitoring the seaming process to ensure consistent and accurate closure.

- Performing regular maintenance and calibration of the seaming machine.

4. What are the common defects that can occur during can capping and how do you resolve them?

- Overlapping seams: Caused by incorrect machine settings or worn-out parts; adjust settings or replace parts.

- Wrinkled seams: Caused by improper can handling or defective lids; adjust handling procedures or inspect lids.

- Undersized seams: Caused by improper seaming machine settings or operator error; adjust settings or retrain operator.

5. How do you maintain and troubleshoot can capping machines?

Regular maintenance is essential for optimal performance. I perform daily inspections, clean and lubricate moving parts, and replace worn-out components as needed. For troubleshooting, I follow a systematic approach to identify the source of the issue and implement appropriate solutions.

6. What is the importance of quality control in can capping?

Quality control is paramount in ensuring the integrity and safety of the products. I conduct thorough inspections throughout the capping process, including visual checks, leak testing, and sampling. Any defective cans are identified and removed to maintain high product standards.

7. How do you stay up-to-date with the latest advancements in can capping technology?

I actively participate in industry conferences and workshops to learn about new developments and best practices. I also regularly read trade publications and consult with manufacturers to stay informed about emerging technologies and innovative solutions.

8. What are your strengths and weaknesses as a can capper?

- Strengths: Extensive experience, attention to detail, problem-solving skills.

- Weaknesses: Occasional time constraints when handling large production volumes (actively working on improving time management).

9. How do you prioritize your tasks and manage your time effectively?

I prioritize tasks based on urgency and importance, using a to-do list and setting deadlines for each task. I also break down large tasks into smaller, more manageable steps to improve efficiency. Additionally, I regularly evaluate my workflow and seek ways to optimize it.

10. Tell me about a time you faced a challenging situation in can capping and how you overcame it.

During a production rush, our primary capping machine malfunctioned, causing a significant backlog of cans. I quickly assessed the situation, identified the root cause, and implemented a temporary solution using a backup machine. While it reduced the output slightly, it allowed us to continue production and meet our deadlines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Capper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Capper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Cappers play a vital role in beverage and food packaging industries. They are responsible for ensuring that cans are properly sealed and capped to maintain product quality and safety.

1. Quality Assurance

Can Cappers are responsible for ensuring the quality of the cans they cap. They check for any defects or damage to the cans before capping them. They also ensure that the caps are properly sealed and that there are no leaks.

- Inspect cans for any defects or damage prior to capping.

- Confirm that caps are properly sealed and there are no leaks.

2. Production Efficiency

Can Cappers must adhere to production targets and maintain efficiency in their work. They work in a fast-paced environment and must be able to keep up with the demand.

- Meet production targets by capping a specific number of cans per hour.

- Maintain a clean and organized work area to ensure efficiency.

3. Equipment Maintenance

Can Cappers are responsible for basic maintenance of the capping equipment. They perform routine cleaning and lubrication tasks to ensure the smooth operation of the machinery.

- Clean and lubricate capping equipment according to established maintenance schedules.

- Report any equipment malfunctions or issues to the supervisor.

4. Safety and Compliance

Can Cappers must comply with all safety regulations and procedures in the workplace. They follow proper lifting techniques and wear appropriate safety gear to prevent accidents.

- Follow established safety regulations and procedures to prevent accidents.

- Use proper lifting techniques and wear appropriate safety gear.

Interview Tips

Preparing thoroughly for a Can Capper interview can significantly increase your chances of success. Here are some key tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company you are applying to and the specific Can Capper position. This will give you a better understanding of the company’s culture, values, and the requirements of the role.

- Visit the company website and read about their history, mission, and products.

- Check industry news and articles to stay informed about the latest developments in the field.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers in advance. This will help you feel more confident and articulate during the interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering questions about your knowledge of the industry and the specific Can Capper role.

3. Highlight Relevant Skills and Experience

In your interview, emphasize your relevant skills and experience that align with the job requirements. Use specific examples to demonstrate your abilities.

- Mention any previous experience in the beverage or food packaging industry.

- Highlight your attention to detail, quality assurance skills, and ability to work in a fast-paced environment.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details or express your enthusiasm for the role.

- Ask about the company’s plans for future growth.

- Inquire about opportunities for professional development and advancement.

5. Follow Up Professionally

After the interview, send a thank-you note to the interviewer. This is a simple but effective way to reiterate your interest in the position and leave a positive impression.

- Send a personalized thank-you note within 24 hours of the interview.

- Reiterate your key qualifications and express your enthusiasm for the role.

Next Step:

Now that you’re armed with the knowledge of Can Capper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Can Capper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini