Are you gearing up for a career in Can Closing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Can Closing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

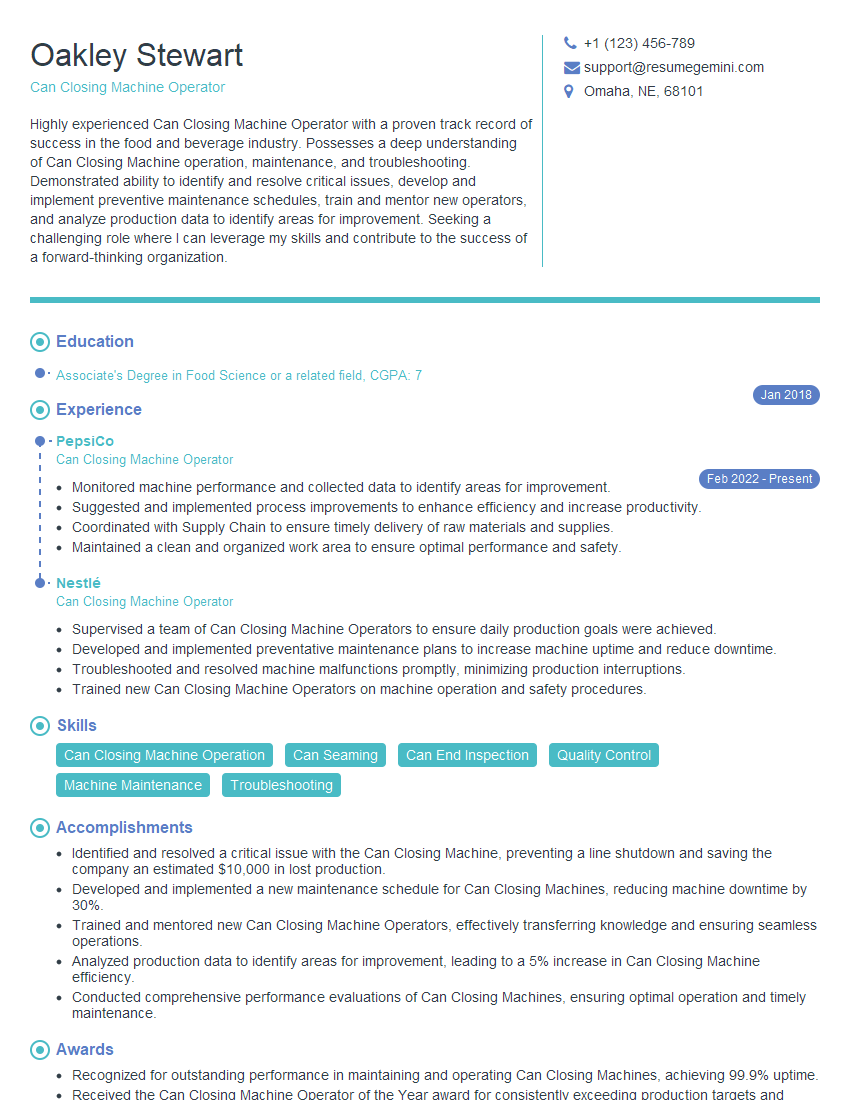

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Closing Machine Operator

1. Explain the process of setting up a can closing machine?

To set up a can closing machine, I follow these steps:

- Inspect the machine: I check for any damage or wear on the machine’s components.

- Install the can closing head: I select the appropriate head for the can size and type, and install it securely.

- Adjust the seaming rollers: I adjust the rollers to the correct position and pressure according to the can specifications.

- Set the closing speed: I program the machine to close cans at the desired speed.

- Calibrate the sensors: I calibrate the sensors to detect the presence of cans and ensure proper can handling.

2. What are the different types of can closing machines and their applications?

Rotary can closing machines

- High-speed operation: Suitable for high-volume production lines.

- Accurate and consistent sealing: Delivers reliable can closures.

Double seaming machines

- Versatile: Can handle a wide range of can sizes and types.

- Manual or semi-automatic operation: Adaptable to different production requirements.

3. How do you troubleshoot a can closing machine that is not sealing cans properly?

When troubleshooting a can closing machine, I follow these steps:

- Check the seaming rollers: Ensure they are properly adjusted and in good condition.

- Inspect the can closing head: Look for signs of wear or damage that could affect sealing.

- Examine the sensors: Verify that they are calibrated and functioning correctly.

- Adjust the closing speed: Too fast or slow speed can impact seal quality.

- Check the lubrication system: Ensure it is working properly to prevent friction and wear.

4. What is the importance of maintaining a can closing machine?

Maintaining a can closing machine is crucial for:

- Ensuring product quality: Proper maintenance prevents leaks and ensures the safety of canned products.

- Optimizing production efficiency: Regular maintenance minimizes downtime and maximizes productivity.

- Reducing maintenance costs: Timely maintenance helps prevent major repairs and extends the machine’s lifespan.

- Ensuring safety: Well-maintained machines minimize the risk of accidents or injuries.

5. How do you ensure the safety of a can closing machine?

- Regular inspections: I conduct routine checks to identify any potential hazards.

- Proper guarding: I verify that all moving parts are adequately guarded to prevent contact.

- Lockout/tagout procedures: I follow established protocols to ensure the machine is isolated during maintenance.

- Emergency stop buttons: I ensure that emergency stop buttons are accessible and functional.

- Operator training: I provide comprehensive training to operators on safety protocols and machine operation.

6. What are the different types of cans that can be closed using a can closing machine?

- Aluminum cans: Used for beverages, food products, and aerosols.

- Tinplate cans: Traditionally used for canned foods and industrial products.

- Plastic cans: Used for packaging food products, such as dairy and juices.

- Combi-cans: Made from a combination of materials, such as paper, plastic, and metal.

7. How do you adjust the seaming rollers to ensure proper can closure?

- Measure can height: I measure the height of the can to determine the correct roller position.

- Set roller gap: I adjust the distance between the rollers based on the can height and specifications.

- Calibrate sensors: I calibrate the sensors to detect the presence of cans and initiate the closing process.

- Test and fine-tune: I run a few test cans to verify the closure quality and make any necessary fine adjustments.

8. What are the common causes of can closure defects and how do you prevent them?

Causes:

- Improper roller adjustment: Incorrect roller gap can lead to under-sealing or over-seaming.

- Damaged seaming head: Wear or damage can affect the sealing process.

- Can deformation: Dents or distortions can hinder proper sealing.

- Inadequate lubrication: Insufficient lubrication can increase friction and cause sealing issues.

Prevention:

- Regular maintenance: Scheduled maintenance helps prevent roller misalignment and seaming head damage.

- Careful handling: Proper handling of cans minimizes deformation.

- Proper lubrication: Following the recommended lubrication schedule reduces friction.

9. How do you optimize the speed of a can closing machine while maintaining seal quality?

- Adjusting roller pressure: Increasing roller pressure can improve seal strength, allowing for higher closing speeds.

- Optimizing seaming head design: Certain head designs can increase closing efficiency without compromising seal quality.

- Lubrication: Proper lubrication reduces friction, allowing for smoother operation at higher speeds.

- Regular maintenance: Well-maintained machines operate more efficiently and can handle higher speeds.

10. How do you stay updated on the latest advancements in can closing technology?

- Industry publications: I subscribe to trade magazines and journals to stay informed about new technologies.

- Conferences and exhibitions: I attend industry events to learn about the latest developments and equipment.

- Vendor communication: I maintain relationships with equipment manufacturers and vendors to receive updates and training.

- Online resources: I explore industry websites and forums to gather information on best practices and innovative solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Closing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Closing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Closing Machine Operators are responsible for overseeing the operation of machines that seal food and beverage cans. They play a crucial role in ensuring the safety and quality of products while maintaining efficiency and productivity.

1. Machine Operation and Monitoring

Operate and monitor can closing machines to seal cans filled with food or beverages.

- Set up and adjust machine settings to meet product specifications.

- Monitor machine operation, detect malfunctions, and take corrective actions to minimize downtime.

2. Quality Control

Inspect cans for defects, such as leaks, dents, or misalignments.

- Perform sensory evaluations to ensure product quality.

- Maintain records of quality checks and report any nonconformities.

3. Maintenance and Troubleshooting

Perform routine maintenance tasks, such as cleaning and lubricating machines.

- Troubleshoot and resolve machine malfunctions independently or by coordinating with maintenance personnel.

- Adhere to established safety protocols and follow lockout/tagout procedures.

4. Compliance and Training

Follow all relevant safety regulations and industry standards.

- Train new operators on machine operation and safety procedures.

- Participate in continuous improvement initiatives to enhance productivity and efficiency.

Interview Tips

A successful interview begins with thorough preparation. Here are some key tips to help you ace your interview for a Can Closing Machine Operator position:

1. Research the Company and Position

Learn about the company’s values, mission, and products. Research the specific requirements of the Can Closing Machine Operator role and identify the skills and experience that align with your qualifications.

- Visit the company’s website and social media pages.

- Read industry publications and articles related to can closing.

2. Practice Common Interview Questions

Prepare answers to frequently asked interview questions. This will not only boost your confidence but also demonstrate your readiness for the job.

- Example Outline:

- Tell me about yourself and your experience in can closing operations.

- Describe a time you successfully resolved a machine malfunction.

- How do you ensure the quality of canned products?

3. Highlight Your Skills and Experience

Quantify your accomplishments and provide specific examples that showcase your abilities. Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Example Outline:

- Reduced machine downtime by 15% through proactive maintenance.

- Implemented a quality control program that resulted in a 20% reduction in product defects.

4. Be Enthusiastic and Professional

Show the interviewer that you are excited about the opportunity. Maintain eye contact, speak clearly, and ask thoughtful questions. Dress professionally and arrive on time for your interview.

- Be prepared to discuss your career goals and how this position aligns with them.

- Ask about the company’s training and development opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Can Closing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!