Feeling lost in a sea of interview questions? Landed that dream interview for Can Crimper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Can Crimper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

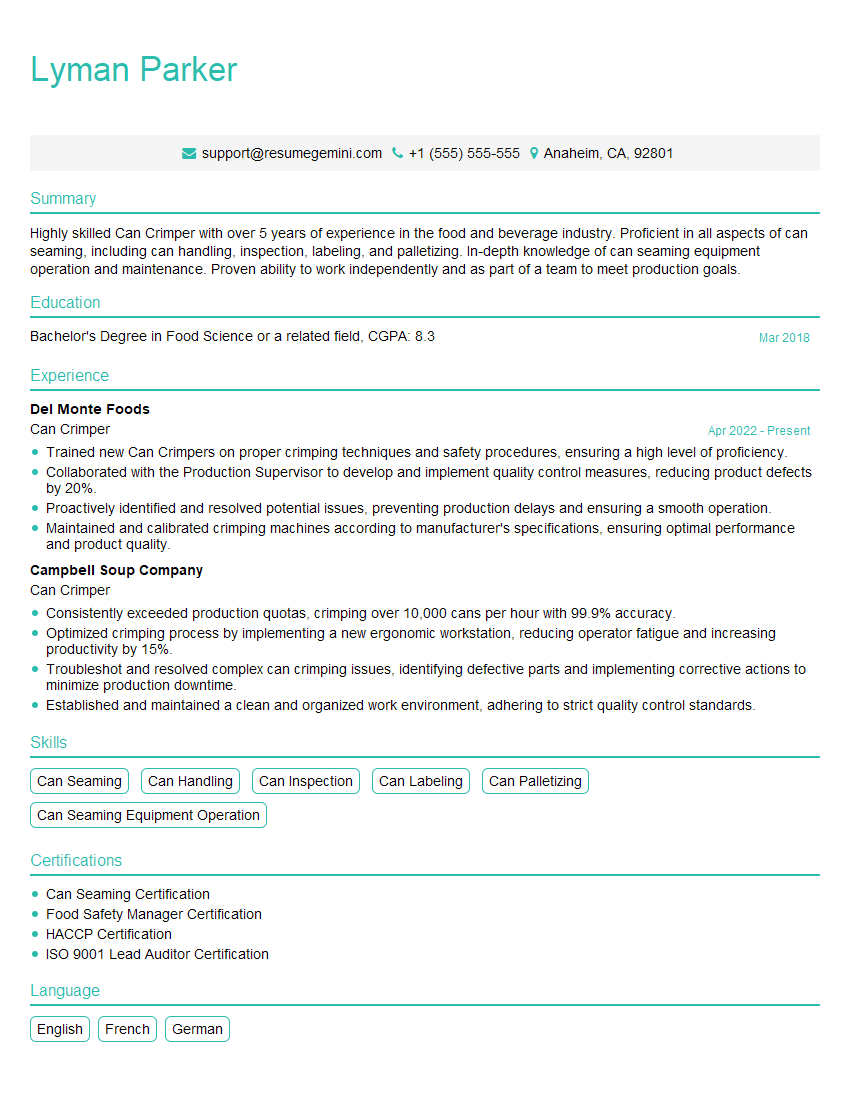

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Crimper

1. What is the primary function of a can crimper?

The primary function of a can crimper is to seal the lid onto a can by crimping the metal lip of the lid onto the rim of the can.

2. What is the difference between a single head can crimper and a double head can crimper?

A single head can crimper has one crimping head, while a double head can crimper has two crimping heads. This allows the double head can crimper to seal two cans at the same time, increasing production speed.

3. What are the different types of can crimping machines?

There are two main types of can crimping machines: manual can crimping machines and automatic can crimping machines. Manual can crimping machines are operated by hand, while automatic can crimping machines are powered by electricity or compressed air.

4. What are the main components of a can crimping machine?

- Crimping head

- Crimping dies

- Conveyor belt

- Control panel

5. What are the safety precautions that should be taken when operating a can crimping machine?

- Wear safety glasses

- Wear gloves

- Keep hands away from moving parts

- Do not operate the machine if it is damaged

6. What are the common problems that can occur with can crimping machines?

- Leaking cans

- Dented cans

- Broken crimping dies

- Electrical problems

7. How do you troubleshoot a leaking can?

- Check the crimping dies for damage

- Check the conveyor belt for damage

- Check the control panel for loose connections

- Check the can for damage

8. How do you replace a broken crimping die?

- Turn off the machine and unplug it

- Remove the old crimping die

- Install the new crimping die

- Tighten the screws

- Plug in the machine and turn it on

9. How do you calibrate a can crimping machine?

- Use a calibration can

- Run the can through the machine

- Adjust the crimping dies until the can is sealed properly

- Repeat steps 2-3 until the machine is calibrated

10. What are the quality control checks that should be performed on canned products?

- Check the cans for leaks

- Check the cans for dents

- Check the cans for proper sealing

- Check the cans for correct labeling

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Crimper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Crimper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Crimpers are responsible for assembling and maintaining can-making machinery. They operate and maintain machines that produce cans for food and beverage products.

1. Machine Operation

Can crimpers operate can-making machines that fold, crimp, and seal the ends of cans. They ensure that the cans are properly formed and sealed to meet quality standards.

- Monitor and adjust machine settings to ensure proper operation

- Troubleshoot and resolve machine malfunctions

- Maintain and clean machines to ensure optimal performance

2. Production Monitoring

Can crimpers monitor the production process to ensure that cans are produced according to specifications. They make adjustments to the machines as needed to maintain production quality and efficiency.

- Inspect cans for defects and reject any that do not meet standards

- Monitor production output to ensure that it meets production targets

- Make adjustments to machine settings to optimize production

3. Quality Control

Can crimpers ensure that the cans produced meet quality standards. They perform various tests to check the strength, sealing, and appearance of the cans.

- Conduct quality control tests to ensure that cans meet specifications

- Identify and resolve any quality issues

- Maintain quality control records

4. Maintenance and Repair

Can crimpers perform routine maintenance and repairs to ensure that machines are operating properly. They also follow maintenance schedules to prevent breakdowns and ensure optimal performance.

- Lubricate and adjust machine components

- Replace worn or damaged parts

- Perform preventative maintenance to prevent breakdowns

Interview Tips

Preparing for an interview can be daunting, but following these tips can help you make a great impression and increase your chances of landing the job.

1. Research the Company and Position

Take the time to learn about the company and the specific position you’re applying for. This shows the interviewer that you’re genuinely interested in the role and the company. Researching the company’s culture, values, and recent news will help you answer questions thoughtfully and demonstrate that you’re a good fit.

- Review the company website and social media pages

- Read industry news and articles

- Talk to your network to see if anyone has any insights

2. Prepare Your Answers to Common Interview Questions

There are certain questions that are commonly asked in job interviews. By preparing your answers to these questions beforehand, you can feel more confident and articulate during the interview. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your salary expectation?

3. Practice Your Delivery

Once you have prepared your answers, practice delivering them out loud. This will help you become more comfortable and confident in your delivery. It’s also a good idea to ask a friend or family member to mock interview you. This can give you feedback on your body language, eye contact, and overall demeanor.

- Practice in front of a mirror

- Record yourself and watch it back

- Ask a friend or family member to mock interview you

4. Be Enthusiastic and Positive

Your enthusiasm and positivity will shine through in the interview. Be excited about the opportunity and demonstrate your passion for the role. Remember to smile and make eye contact with the interviewer.

- Show your enthusiasm for the role

- Be positive and upbeat

- Make eye contact and smile

Next Step:

Now that you’re armed with the knowledge of Can Crimper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Can Crimper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini