Are you gearing up for an interview for a Can Filler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Can Filler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

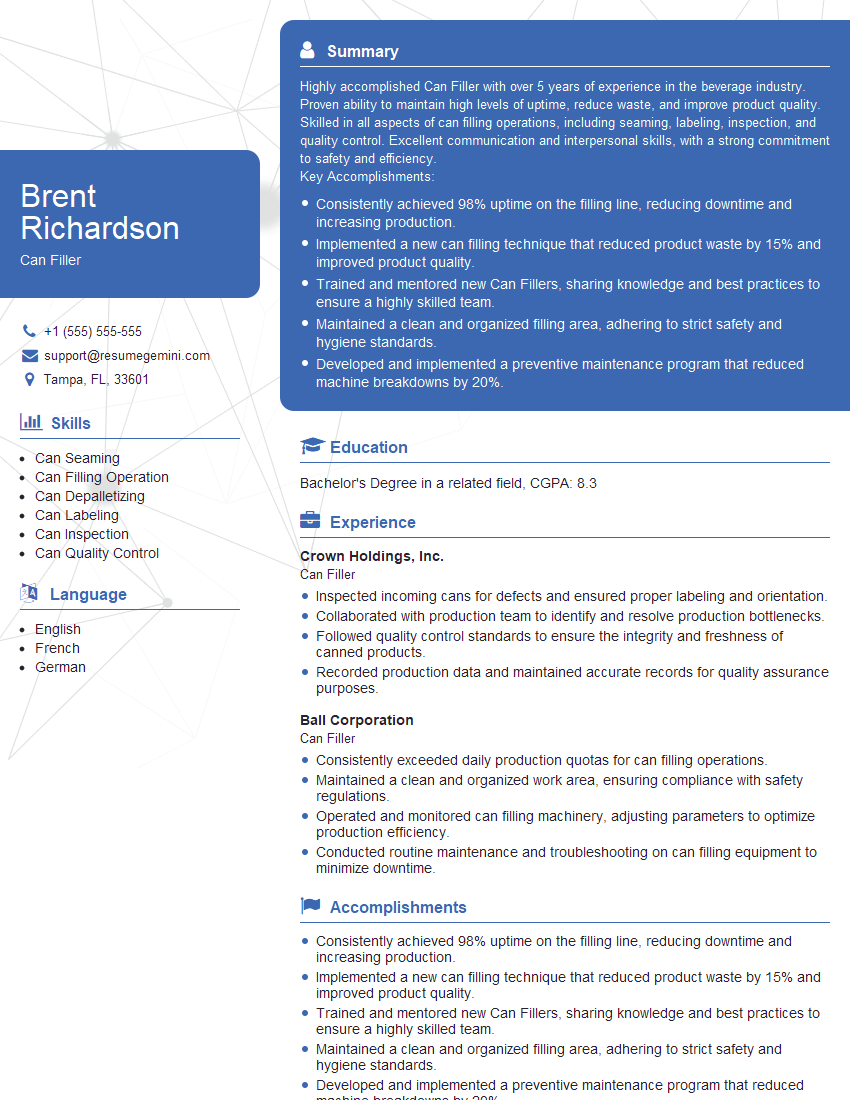

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Filler

1. Explain the process of can filling and sealing operation?

The process of can filling and sealing operation involves several key steps:

- Can preparation: Cans are inspected for defects and cleaned to ensure sterility.

- Product filling: The product is dispensed into the cans, typically using a filling machine.

- Can seaming: The cans are sealed with a lid using a seaming machine, creating an airtight and tamper-proof container.

- Can sterilization: The filled and sealed cans may undergo sterilization, such as pasteurization or retort processing, to eliminate potential microorganisms.

- Inspection and quality control: The filled and sealed cans are inspected for leaks and other abnormalities to ensure product integrity.

2. Describe the different types of can fillers and their applications?

Rotary can fillers:

- High-speed machines suitable for large-scale production.

- Multiple filling heads rotate around a central carousel, filling cans simultaneously.

Inline can fillers:

- Used for smaller production runs and more flexible operations.

- Cans are conveyed through a series of filling stations, including a volumetric filler, seamer, and sterilization unit.

Gravity fillers:

- Simple and cost-effective, suitable for low-viscosity products.

- Product flows by gravity into open cans, filling them to a predetermined level.

Pressure fillers:

- Used for viscous products that require pressure to dispense.

- Product is pumped into the cans using a piston or diaphragm.

3. What are the critical control points (CCPs) in a can filling operation and how are they monitored?

The critical control points (CCPs) in a can filling operation include:

- Can cleaning and sterilization: Ensures removal of contaminants and microorganisms.

- Filling accuracy: Maintains consistent product volume within specifications.

- Can sealing integrity: Prevents product leakage and contamination.

- Sterilization: Eliminates potential spoilage organisms.

- Cooling: Prevents product spoilage and ensures optimal shelf life.

These CCPs are monitored using various methods, such as:

- Temperature measurement

- Pressure monitoring

- Visual inspection

- Microbial testing

- Statistical process control (SPC)

4. Discuss the importance of can filling equipment maintenance and how it impacts product quality?

Regular maintenance of can filling equipment is essential for:

- Ensuring accurate filling: Worn or malfunctioning equipment can lead to underfilling or overfilling, affecting product quality and consistency.

- Maintaining sealing integrity: Proper maintenance prevents leaks, contamination, and product spoilage.

- Optimizing production efficiency: Well-maintained equipment minimizes downtime, reduces waste, and increases productivity.

- Enhancing product safety: Regular maintenance ensures that the equipment operates safely, reducing potential hazards to operators and consumers.

5. Describe the challenges associated with filling and sealing different types of products in cans?

Different products present unique challenges in can filling and sealing:

- Viscosity: Viscous products require specialized filling equipment to ensure consistent flow and accurate volume.

- Foaming: Products that tend to foam require careful handling to prevent overflow and minimize product loss.

- Particulates: Products with solid particles or suspended solids may require special filling techniques to prevent clogging.

- Carbonation: Carbonated beverages require careful filling and sealing to maintain carbonation levels and prevent pressure buildup.

- Aseptic packaging: Sterile products require aseptic filling and sealing to prevent contamination.

6. Explain the role of sanitary design in can filling and sealing operations?

Sanitary design principles are crucial in can filling and sealing operations to:

- Minimize contamination: Equipment surfaces are designed to prevent product accumulation and harboring of microorganisms.

- Facilitate cleaning and maintenance: Equipment is easily accessible and disassembled for thorough cleaning and sanitization.

- Comply with regulations: Sanitary design meets regulatory requirements for food and beverage processing.

7. Discuss the latest advancements in can filling and sealing technology?

Recent advancements in can filling and sealing technology include:

- High-speed filling: Advanced fillers achieve higher speeds with improved accuracy and efficiency.

- Automated inspection systems: Vision systems and sensors inspect cans for defects and contamination.

- Aseptic filling and sealing: New technologies enable sterile filling and sealing in aseptic environments.

- Data analytics and IoT: Sensors collect data on equipment performance and product quality, enabling real-time monitoring and optimization.

8. Explain the importance of quality control in can filling and sealing?

Quality control in can filling and sealing is essential for:

- Product safety: Ensures that products meet safety standards and are free from contamination.

- Product quality: Maintains consistent product quality, taste, and appearance.

- Compliance: Meets regulatory requirements and industry standards.

- Customer satisfaction: Delivers high-quality products that meet customer expectations.

9. Describe the troubleshooting process for common problems encountered in can filling and sealing operations?

Troubleshooting common problems in can filling and sealing involves:

- Identifying the problem: Determine the symptoms, frequency, and potential causes.

- Analyzing the equipment: Inspect the equipment for mechanical failures, leaks, or blockages.

- Adjusting parameters: Optimize filling speeds, temperatures, and other settings.

- Cleaning and maintenance: Ensure that equipment is clean and well-maintained.

- Consulting with experts: Seek assistance from manufacturers, engineers, or technical professionals.

10. Explain the importance of teamwork and communication in a can filling and sealing operation?

Teamwork and communication are crucial in can filling and sealing operations for:

- Coordinating tasks: Operators, supervisors, and maintenance personnel work together to ensure smooth operation.

- Problem-solving: Team members collaborate to troubleshoot and resolve issues efficiently.

- Maintaining safety: Clear communication helps prevent accidents and ensures a safe work environment.

- Improving productivity: Effective communication facilitates knowledge sharing and continuous improvement efforts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Can Filler is responsible for operating and maintaining the can filling machine and ensuring that cans are filled to the correct level and sealed properly. They also perform quality control checks on the filled cans to ensure that they meet the company’s standards.

1. Operate and maintain the can filling machine

This involves setting up the machine, loading the cans, and starting the filling process. The Can Filler must also monitor the machine during operation and make any necessary adjustments to ensure that it is running smoothly.

- Set up the can filling machine according to the manufacturer’s instructions.

- Load the cans into the machine.

- Start the filling process.

- Monitor the machine during operation.

- Make any necessary adjustments to the machine to ensure that it is running smoothly.

2. Perform quality control checks on the filled cans

This involves checking the cans for leaks, proper fill level, and seal integrity. The Can Filler must also check the cans for any other defects that could affect the quality of the product.

- Check the cans for leaks.

- Check the cans for proper fill level.

- Check the cans for seal integrity.

- Check the cans for any other defects that could affect the quality of the product.

3. Clean and maintain the can filling machine

This involves cleaning the machine on a regular basis to prevent the build-up of dirt and debris. The Can Filler must also perform any necessary maintenance on the machine to ensure that it is in good working order.

- Clean the can filling machine on a regular basis.

- Perform any necessary maintenance on the machine.

4. Other duties as assigned

The Can Filler may also be required to perform other duties as assigned by their supervisor. These duties may include:

- Loading and unloading cans.

- Storing and inventorying cans.

- Assisting with other production tasks.

Interview Tips

Here are some tips to help you ace your interview for a Can Filler position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find this information on the company’s website, in industry publications, or by talking to people who work for the company.

- Visit the company’s website.

- Read industry publications.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice your answers to common interview questions.

- Deliver your answers confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in the food and beverage industry and specifically in can filling. Be prepared to talk about your skills and knowledge in this area and how they can benefit the company.

- Be prepared to talk about your experience in the food and beverage industry.

- Discuss your skills and knowledge in can filling.

- Explain how your skills and knowledge can benefit the company.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include:

- “What are the biggest challenges facing the company right now?”

- “What is the company’s culture like?”

- “What are the opportunities for advancement within the company?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Can Filler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.