Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Can Filling and Closing Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Can Filling and Closing Machine Tender so you can tailor your answers to impress potential employers.

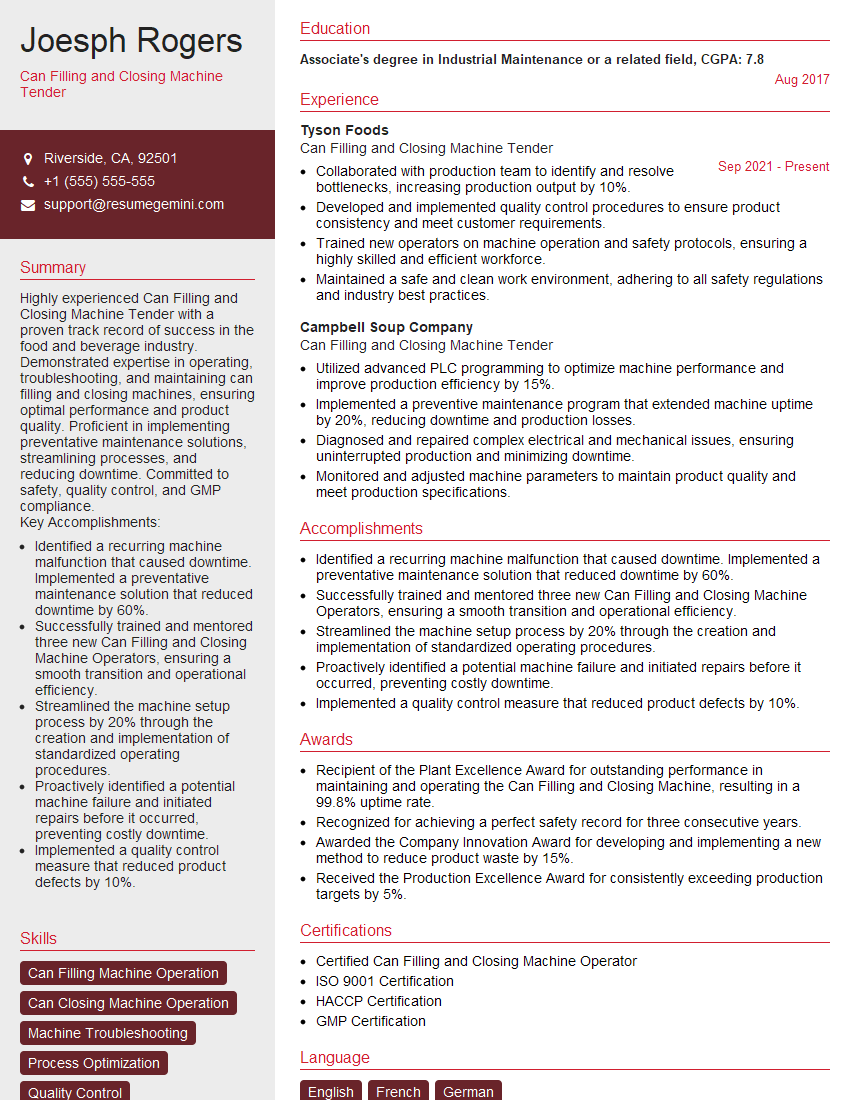

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Filling and Closing Machine Tender

1. Explain the process of adjusting a can filling machine for different can sizes?

Sample Answer:

- Assess the new can size and the machine settings required.

- Adjust the fill valve height, volume settings, and conveyor speed accordingly.

- Fill and seal a test can to verify proper operation.

- Make any necessary fine-tuning adjustments to optimize performance.

2. How do you troubleshoot and resolve a faulty seaming operation on a can filling and closing machine?

Identifying the Cause

- Inspect the seaming rollers for wear or damage.

- Check the can height and ensure it matches the machine settings.

- Verify the proper adjustment of the seaming pressure.

Resolving the Issue

- Replace worn or damaged rollers.

- Adjust the can height and machine settings accordingly.

- Calibrate the seaming pressure to the recommended specifications.

- Inspect the cans to ensure proper sealing and no leakage.

3. Describe the maintenance procedures you perform on a can filling and closing machine?

Sample Answer:

- Regularly clean and lubricate all moving parts.

- Inspect and replace filters and seals as needed.

- Calibrate the machine according to manufacturer specifications.

- Monitor and adjust the fill volume and seaming pressure.

- Perform general machine checks and repairs as required.

4. How do you ensure the quality of the cans produced by the machine?

Sample Answer:

- Inspect cans for proper fill levels and seal integrity.

- Perform leak tests to verify the effectiveness of the seaming operation.

- Monitor the machine’s performance and make adjustments as needed to maintain quality.

- Collaborate with quality control personnel to meet product specifications.

5. Describe your experience with different types of can filling and closing machines?

Sample Answer:

- Experience with high-speed filling machines for both liquid and dry products.

- Proficient in operating and maintaining rotary seamers for various can sizes.

- Knowledge of inline inspection systems to ensure product integrity.

- Familiarity with automation and PLC programming for machine optimization.

6. How do you ensure personal and machine safety when working on a can filling and closing machine?

Sample Answer:

- Follow established safety protocols and wear appropriate PPE.

- Lock out and tag out the machine before performing maintenance.

- Stay alert and be aware of potential hazards around the machine.

- Report any safety concerns or incidents promptly.

- Receive regular training on safe operating procedures.

7. What are the key factors that affect the efficiency of a can filling and closing machine?

Sample Answer:

- Proper machine setup and calibration.

- Regular maintenance and lubrication.

- Optimal filling and seaming parameters.

- High-quality cans and product.

- Skilled and experienced operators.

8. How do you optimize the production process of a can filling and closing machine to maximize output?

Sample Answer:

- Fine-tune machine settings for optimal performance.

- Use high-speed filling and seaming techniques.

- Reduce downtime by proactive maintenance and troubleshooting.

- Implement automation and data collection for process optimization.

- Collaborate with upstream and downstream processes to minimize disruptions.

9. What are the common challenges you have encountered while operating a can filling and closing machine, and how did you overcome them?

Sample Answer:

- Problem: Faulty seaming due to worn rollers.

- Solution: Inspected and replaced the rollers.

- Problem: Product leakage due to incorrect fill volume.

- Solution: Calibrated the filling valve and adjusted the volume settings.

- Problem: Machine downtime due to a faulty sensor.

- Solution: Diagnosed the issue and replaced the sensor, minimizing downtime.

10. How do you stay up-to-date with the latest industry trends and advancements in can filling and closing technology?

Sample Answer:

- Attend industry conferences and seminars.

- Read trade publications and online resources.

- Participate in manufacturer training programs.

- Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Filling and Closing Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Filling and Closing Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Filling and Closing Machine Tenders operate and maintain machinery that fills and seals cans with food or beverage products. They also perform quality control checks on the finished products.

1. Operate can filling and closing machinery

This task involves operating a variety of machines, including can fillers, seamers, and labelers.

- Load cans into the filling machine

- Set up the machine for the desired product and container size

- Monitor the machine during operation and make adjustments as needed

2. Perform quality control checks

This task involves inspecting cans for defects, such as dents, scratches, and leaks.

- Inspect cans visually for defects

- Use gauges and other instruments to check for leaks

- Reject defective cans and report any problems to the supervisor

3. Clean and maintain machinery

This task involves cleaning and maintaining the filling and closing machinery to ensure that it is operating properly.

- Clean the machinery regularly with soap and water

- Lubricate moving parts as needed

- Inspect the machinery for wear and tear and make repairs as needed

4. Follow safety procedures

This task involves following all safety procedures to ensure the safety of themselves and others.

- Wear appropriate safety gear, such as gloves and earplugs

- Follow lockout/tagout procedures when working on machinery

- Report any safety hazards to the supervisor

Interview Tips

Interviews can be nerve-wracking, but there are steps you can take to prepare to ace the interview for a Can Filling and Closing Machine Tender position.

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you to better understand the company’s culture and the requirements of the job.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Use the STAR method to answer behavioral questions

- Tailor your answers to the specific job you are applying for

- Practice your answers with a friend or family member

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This will show the interviewer that you are respectful of their time.

- Choose clothing that is clean, pressed, and fits well

- Avoid wearing clothing that is too revealing or too casual

- Plan your route to the interview in advance so that you can avoid getting lost or being late

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. It is also a chance for you to show the interviewer that you are interested in the job and that you have done your research.

- Ask questions about the company’s culture

- Ask about the specific responsibilities of the position

- Ask about the company’s plans for the future

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Can Filling and Closing Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Can Filling and Closing Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.