Are you gearing up for a career in Can Labeler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Can Labeler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

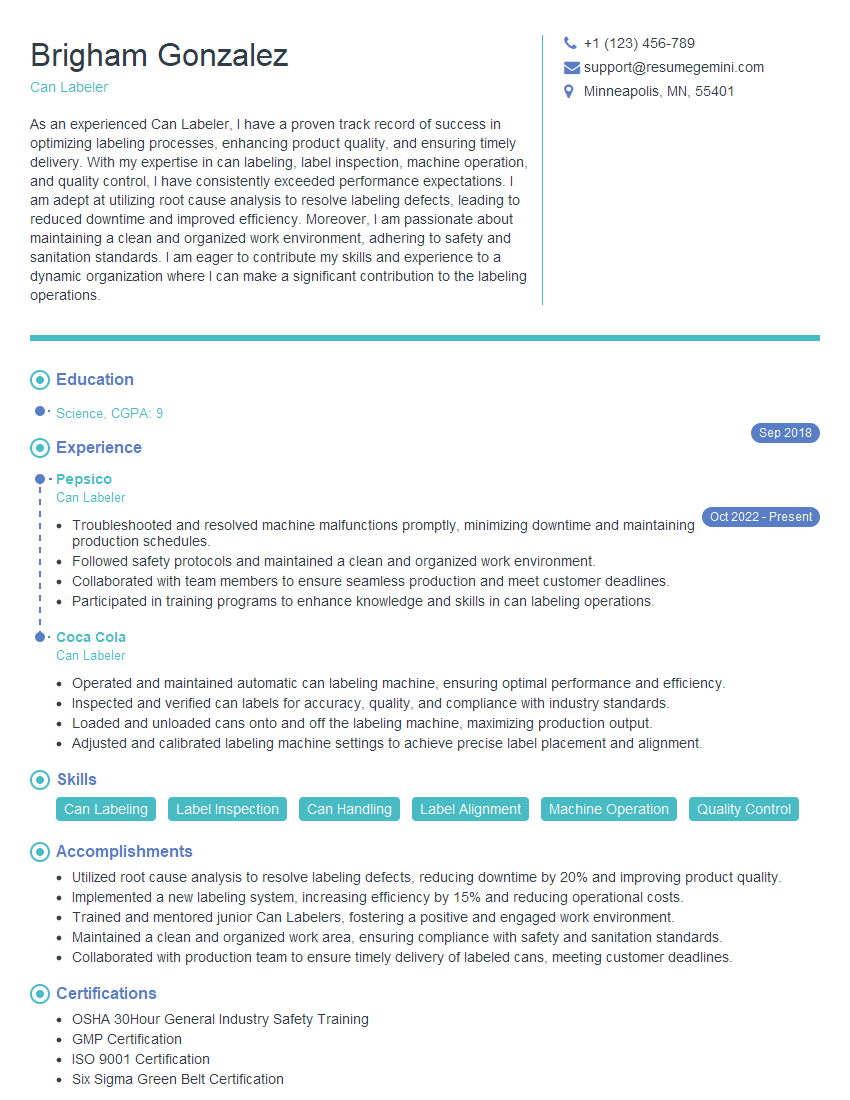

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Labeler

1. What are the different types of labeling machines used in the industry?

There are several types of labeling machines used in the industry, including:

- Pressure Sensitive Label Applicators

- Roll Fed Labeling Machines

- Sleeve Labeling Machines

- Wrap-Around Labelers

- Shrink Sleeve Labelers

2. What are the key factors to consider when selecting a labeling machine?

- Product shape and size

- Label size and material

- Production speed and efficiency

- Budget and cost of ownership

- Reliability and maintenance requirements

Factors to consider:

3. What are the common issues that can occur during the labeling process and how do you troubleshoot them?

- Label misalignment: Caused by improper settings, worn parts, or product variations. Troubleshooting involves checking settings, replacing worn parts, and optimizing machine parameters.

- Label tearing or wrinkling: Caused by label tension issues, improper label material, or misalignment. Troubleshooting involves adjusting tension settings, using appropriate label material, and ensuring proper alignment.

- Label sticking to the machine: Caused by adhesive buildup, poor quality labels, or improper tension settings. Troubleshooting involves cleaning the machine, using high-quality labels, and optimizing tension settings.

4. How do you ensure accurate and consistent label placement?

- Calibrate the machine: Use a reference point or template to ensure proper alignment and placement.

- Check product dimensions: Verify that the machine is configured for the specific product size and shape.

- Monitor sensor readings: Use sensors to detect product position and adjust label placement accordingly.

- Perform regular maintenance: Regularly clean and inspect the machine to prevent issues that could affect label placement.

5. Describe the safety precautions that must be followed when operating a labeling machine.

- Wear appropriate PPE: Safety glasses, gloves, and ear protection are necessary.

- Guard against moving parts: Keep hands and clothing away from conveyor belts, label applicators, and other moving components.

- Follow lockout/tagout procedures: Ensure the machine is properly shut down and isolated before performing maintenance.

- Report any issues: Immediately report any malfunctions, jams, or other problems to a supervisor.

6. What maintenance tasks are required to keep a labeling machine running smoothly?

- Regular cleaning: Remove label residue, dust, and other contaminants from the machine.

- Lubrication: Apply lubricant to moving parts as per the manufacturer’s instructions.

- Inspections: Check for worn or damaged components, such as belts, rollers, and sensors.

- Calibration: Periodically calibrate the machine to maintain accurate label placement.

7. Explain the importance of using high-quality labels in the labeling process.

- Enhanced product appearance: High-quality labels contribute to a professional and attractive product presentation.

- Improved label adhesion: Durable labels ensure proper adhesion to products, preventing peeling or tearing.

- Enhanced print quality: Vibrant and clear printing on labels improves product visibility and readability.

- Reduced production downtime: Using high-quality labels minimizes machine jams or label tearing, resulting in increased productivity.

8. Describe the different methods used to apply labels to products.

- Pressure-sensitive labeling: Using self-adhesive labels that adhere to the product surface.

- Heat-activated labeling: Applying labels that require heat to activate the adhesive.

- Cold-glue labeling: Using labels with pre-applied adhesive that is activated by moisture.

- In-mold labeling: Embedding labels directly into the plastic or glass container during manufacturing.

9. How can you optimize the labeling process for maximum efficiency?

- Proper machine setup: Ensure the labeling machine is calibrated and optimized for the specific product and label type.

- Label dispenser optimization: Adjust the label dispenser to minimize label waste and ensure smooth label feeding.

- Efficient product handling: Designate specific areas for product loading and unloading to streamline the process.

- Regular maintenance: Perform regular maintenance tasks to prevent downtime and ensure consistent performance.

10. What is your experience with quality control in the labeling process?

In my previous role as a Can Labeler, I was responsible for ensuring the accuracy and quality of labels applied to cans. I implemented a comprehensive quality control system that involved:

- Visual inspection: Inspecting each labeled can for proper label alignment, adhesion, and print quality.

- Automated checking: Using a machine vision system to detect any defects or inconsistencies in label placement or printing.

- Statistical process control: Monitoring key performance indicators (KPIs) and implementing corrective actions to maintain high-quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Labeler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Labeler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Labelers are responsible for operating and maintaining labeling machines that apply labels to cans. They ensure that the labels are applied accurately and consistently, and that the machines are running smoothly and efficiently.

1. Machine Operation

Operate and maintain labeling machines to apply labels to cans

- Load and unload cans from the labeling machine

- Inspect cans for defects before labeling

- Adjust machine settings to ensure accurate and consistent label application

- Monitor machine performance and make necessary adjustments

2. Label Application

Ensure that labels are applied accurately and consistently

- Inspect labels for defects before application

- Apply labels to cans using the appropriate adhesive

- Check labeled cans for defects

- Remove and replace defective labels

3. Machine Maintenance

Perform basic maintenance on labeling machines

- Clean and lubricate machine parts

- Inspect machine for wear and tear

- Replace worn or damaged parts

- Troubleshoot and resolve machine problems

4. Quality Control

Ensure that labeled cans meet quality standards

- Inspect labeled cans for defects

- Remove and replace defective cans

- Maintain records of inspection and quality control activities

- Follow established quality control procedures

Interview Tips

Preparing for a job interview can be a daunting task, but it doesn’t have to be. By following these tips, you can increase your chances of making a great impression and landing the job you want.

1. Research the Company

Take some time to learn about the company you’re applying to. This will give you a better understanding of their culture, values, and goals. You can find this information on the company’s website, social media pages, and Glassdoor.

- Practice answering common interview questions.

- Dress professionally and arrive on time for your interview.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview. You can practice with a friend or family member, or you can use online resources like YouTube or LinkedIn.

- Highlight your skills and experience.

- Be Enthusiastic and professional.

3. Highlight Your Skills and Experience

During your interview, be sure to highlight your skills and experience that are relevant to the job you’re applying for. Use specific examples to demonstrate your abilities and accomplishments.

- Ask thoughtful questions about the company and the position.

- Thank the interviewer for their time.

4. Be Enthusiastic and Professional

It’s important to be enthusiastic and professional during your interview. This will show the interviewer that you’re interested in the job and that you’re a hard worker. Be polite and respectful, and be sure to make eye contact with the interviewer.

- Follow up with the interviewer after the interview.

5. Follow Up

After your interview, be sure to follow up with the interviewer. This is a great way to show your interest in the job and to thank the interviewer for their time. You can send a thank-you note or an email, or you can call the interviewer to check in.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Can Labeler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Can Labeler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.