Are you gearing up for an interview for a Can Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Can Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

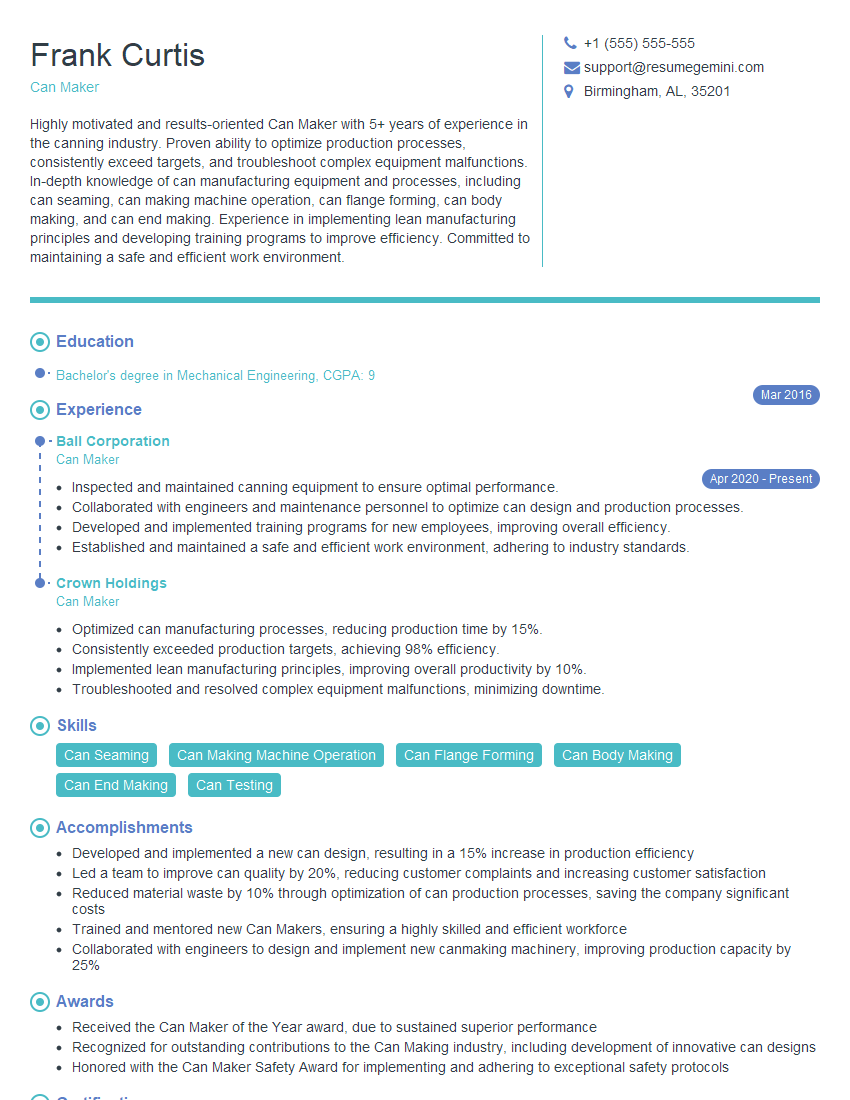

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Maker

1. What are the key steps involved in the can-making process?

The key steps involved in the can-making process include:

- Coil Preparation: Uncoiling and preparing the aluminum or steel coil for the can-making process.

- Cup Forming: Drawing and forming the coil into the shape of a can body or end.

- Body Making: Joining the can body’s sidewalls and attaching the bottom end.

- End Making: Forming and shaping the can’s top and bottom ends.

- Flanging and Nectaring: Preparing the can’s opening by creating a flange and adding a sealant.

- Coating and Printing: Applying protective coatings and printing designs on the can’s exterior and interior.

- Inspection and Quality Control: Ensuring that the cans meet specifications and quality standards.

2. Describe the different types of can materials and their properties.

The different types of can materials and their properties include:

- Aluminum: Lightweight, corrosion-resistant, and recyclable, making it a popular choice for beverage and food cans.

- Steel: Strong, durable, and cost-effective, but heavier than aluminum and more prone to corrosion.

- Tinplate: A steel sheet coated with tin, providing corrosion resistance and solderability, commonly used for food cans.

- Plastic: Lightweight, impact-resistant, and versatile, used for packaging various products.

3. Explain the principles of can seaming and its importance.

Seaming Process:

- Hook Formation: Overlapping the can’s sidewall and end flange.

- Double Seaming: Curling and interlinking the hook to create a hermetic seal.

Importance:

- Ensures product integrity and shelf life.

- Protects contents from contamination and leakage.

- Withstands pressure and temperature variations.

4. Discuss the factors that affect the strength and durability of cans.

- Material Thickness: Thicker materials provide greater strength and durability.

- Can Structure: Design features such as ribs and beading enhance strength.

- Seaming Quality: Proper seaming techniques ensure a strong and leak-proof seal.

- Corrosion Resistance: Protective coatings prevent corrosion and maintain can integrity.

- Handling and Storage: Proper handling and storage practices prevent damage and maintain can quality.

5. Describe the testing methods used to evaluate the quality of cans.

- Leak Testing: Checks for any leaks or imperfections in the can’s seal.

- Pressure Testing: Assesses the can’s ability to withstand internal pressure.

- Burst Testing: Determines the maximum pressure the can can withstand before bursting.

- Visual Inspection: Examines the can’s surface for any defects or imperfections.

- Drop Testing: Evaluates the can’s resistance to impact and damage.

6. Explain the importance of maintaining can tooling and machinery.

- Ensures Optimal Performance: Well-maintained tooling and machinery produce high-quality cans.

- Reduces Downtime: Regular maintenance prevents unexpected breakdowns and minimizes production interruptions.

- Extends Equipment Life: Proper maintenance prolongs the lifespan of can-making equipment.

- Improves Safety: Regular maintenance reduces the risk of accidents and ensures a safe working environment.

- Optimizes Production Efficiency: Efficiently maintained equipment enhances productivity and minimizes waste.

7. Discuss the environmental considerations in the can-making process.

- Material Selection: Choosing recyclable materials and minimizing waste.

- Energy Efficiency: Optimizing energy consumption during the manufacturing process.

- Waste Management: Implementing waste reduction and recycling programs.

- Sustainable Packaging: Designing cans that are both functional and environmentally friendly.

- Compliance with Regulations: Adhering to environmental regulations and standards.

8. Explain the role of automation in modern can-making facilities.

- Increased Production Efficiency: Automation speeds up the can-making process and enhances productivity.

- Improved Quality Control: Automated systems provide consistent and accurate production, reducing defects.

- Reduced Labor Costs: Automation eliminates repetitive tasks, reducing labor requirements and costs.

- Enhanced Safety: Automated processes minimize the need for manual handling, improving workplace safety.

- Data Collection and Analysis: Automation enables the collection and analysis of production data, facilitating continuous improvement.

9. Describe the challenges and opportunities in the can-making industry.

Challenges:

- Fluctuating raw material costs

- Increasing environmental regulations

- Competition from alternative packaging formats

Opportunities:

- Growing demand for sustainable packaging

- Advancements in can-making technology

- Expansion into new markets and applications

10. How do you stay updated with the latest advancements in can-making technology?

- Attend industry conferences and trade shows

- Read technical journals and publications

- Collaborate with equipment manufacturers and suppliers

- Participate in online forums and discussions

- Engage in continuous learning and research

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Makers are responsible for the operation and maintenance of can making machinery, ensuring that cans are produced to the required specifications. Their key responsibilities typically include:

1. Machine Operation and Monitoring

Operate and monitor can making machinery, including can body makers, seamers, and end makers.

2. Machine Maintenance

Perform routine maintenance and repairs on can making machinery, including cleaning, lubrication, and adjustment.

3. Quality Control

Conduct quality checks on cans produced, ensuring that they meet the required specifications.

4. Materials Handling

Handle raw materials and finished cans, including loading and unloading them from machinery.

5. Process Improvement

Identify and implement process improvements to increase efficiency and reduce waste.

6. Safety and Compliance

Follow safety regulations and ensure compliance with industry standards.

Interview Tips

Preparing for a Can Maker interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company and the specific Can Maker position you are applying for. This will help you understand the company’s culture, values, and the key responsibilities of the role.

2. Practice Answering Common Interview Questions

Practice answering common interview questions such as “Tell me about yourself” and “Why are you interested in this position?”. Prepare examples from your experience that demonstrate your skills and qualifications.

3. Highlight Your Technical Skills

Emphasize your technical skills and experience in operating and maintaining can making machinery. Provide specific examples of your abilities and any certifications you hold.

4. Demonstrate Your Quality Control and Safety Awareness

Highlight your attention to detail and commitment to quality control. Explain how you ensure that cans meet the required specifications and adhere to safety regulations.

5. Be Enthusiastic and Professional

Convey your enthusiasm for the Can Maker role and show that you are a professional and motivated individual. Be confident in your abilities and express your willingness to learn and contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Can Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.