Feeling lost in a sea of interview questions? Landed that dream interview for Can Sealer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Can Sealer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

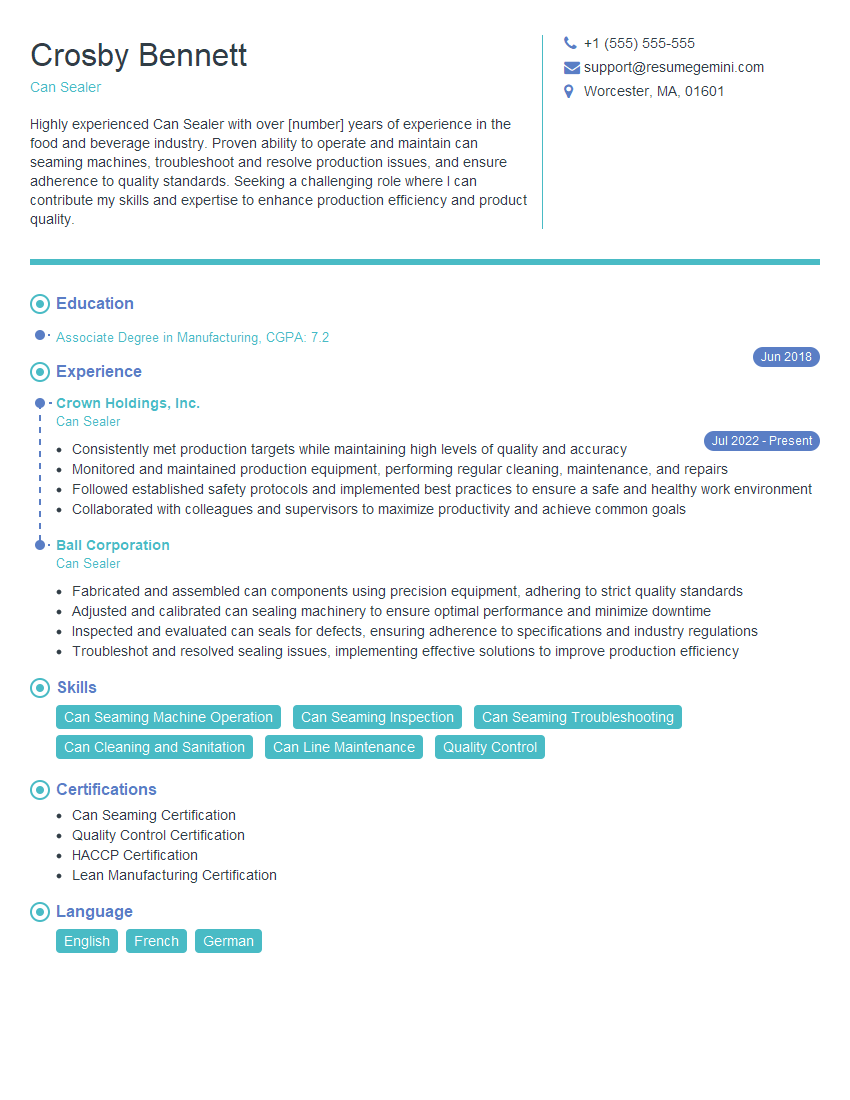

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Sealer

1. Describe the process of sealing a can?

The process of sealing a can involves several steps:

- Can preparation: The can is inspected for any defects and cleaned to remove any contaminants.

- Lid preparation: The lid is also inspected and cleaned, and a gasket or sealant is applied to create a seal.

- Can filling: The can is filled with the product, leaving a small amount of headspace.

- Lid placement: The lid is placed on the can and secured in place using a seaming machine.

- Seaming: The seaming machine creates a hermetic seal between the can and the lid by rolling the edges of the can over the lid.

- Cooling: The sealed can is cooled to room temperature to stabilize the seal.

- Inspection: The sealed can is inspected to ensure that it is properly sealed and free of leaks.

2. Explain the different types of can sealers and their applications?

Double seam sealers

- Most common type of can sealer

- Used for sealing metal cans

- Creates a hermetic seal by rolling the edges of the can over the lid

Single seam sealers

- Less common than double seam sealers

- Used for sealing plastic or composite cans

- Creates a single rolled seam around the circumference of the can

Vacuum sealers

- Used for sealing flexible packaging materials

- Removes air from the package before sealing it

- Creates a hermetic seal to preserve the freshness of the product

3. What are the factors that affect the quality of a can seal?

- Can material: The thickness and type of can material can affect the strength and durability of the seal.

- Lid material: The type of lid material (e.g., aluminum, steel) can also affect the quality of the seal.

- Gasket or sealant: The type and amount of gasket or sealant used can affect the hermeticity of the seal.

- Seaming machine: The accuracy and calibration of the seaming machine is critical to creating a proper seal.

- Operator training: The skill and experience of the operator can also affect the quality of the seal.

4. How do you troubleshoot a can sealer that is not producing quality seals?

- Inspect the can and lid: Check for any defects or damage that could prevent a proper seal.

- Inspect the gasket or sealant: Ensure that the gasket or sealant is applied correctly and in the proper amount.

- Calibrate the seaming machine: Check the calibration of the seaming machine and adjust it if necessary.

- Train the operator: Ensure that the operator is properly trained and following the correct procedures.

- Check the maintenance schedule: Make sure that the can sealer is properly maintained and serviced according to the manufacturer’s recommendations.

5. What are the safety precautions that should be taken when operating a can sealer?

- Wear appropriate safety gear: This includes gloves, safety glasses, and earplugs.

- Keep the work area clean and free of debris: This will help prevent accidents and injuries.

- Never operate the can sealer if it is damaged or malfunctioning: This could lead to serious injury.

- Be aware of the pinch points and moving parts: Keep your hands and body clear of these areas.

- Follow the manufacturer’s instructions for safe operation: This will help ensure that the can sealer is operated safely and effectively.

6. What is your experience with maintaining and repairing can sealers?

I have several years of experience maintaining and repairing can sealers. I am familiar with the different types of can sealers and their components. I am also trained in troubleshooting and repairing common can sealer problems. In my previous role, I was responsible for the maintenance and repair of a fleet of can sealers. I have experience in:

- Troubleshooting and repairing electrical problems

- Adjusting and calibrating can sealers

- Replacing worn or damaged parts

- Performing preventive maintenance

7. What are the latest trends in can sealing technology?

- Increased use of automation: Can sealers are becoming increasingly automated, which can help to improve efficiency and reduce labor costs.

- Development of new can sealing methods: New can sealing methods are being developed to improve the quality and hermeticity of seals.

- Use of sustainable materials: Can sealers are being designed to use more sustainable materials, such as recycled plastics.

8. How do you stay up-to-date on the latest can sealing technology?

- Attend industry conferences and trade shows: This is a great way to learn about the latest can sealing technology and developments.

- Read industry publications: There are several industry publications that cover the latest can sealing technology.

- Network with other can sealing professionals: This is a great way to stay informed about the latest trends and developments in the industry.

9. What are your strengths and weaknesses as a Can Sealer?

My strengths as a Can Sealer include:

- Excellent mechanical skills

- Strong troubleshooting abilities

- Experience with a variety of can sealing equipment

- Commitment to safety

My weaknesses include:

- Lack of experience with some of the latest can sealing technology

- Can be a bit slow at times

10. Why are you interested in working as a Can Sealer for our company?

I am interested in working as a Can Sealer for your company because I am passionate about the canning industry. I believe that my skills and experience would be a valuable asset to your team. I am eager to learn more about your company and the can sealing process. I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Sealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Sealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Sealers are responsible for ensuring the proper and safe operation of can sealing machinery, ensuring the production of high-quality canned goods. Key job responsibilities include:

1. Machine Operation and Monitoring

Operate and monitor can sealing machinery to ensure proper alignment, pressure and temperature settings.

- Maintain optimal machine settings to achieve desired seal quality and efficiency.

- Identify and resolve minor machine malfunctions and perform routine maintenance.

2. Quality Control

Inspect sealed cans for defects, ensuring they meet quality standards and specifications.

- Conduct visual and physical inspections of seals to identify any irregularities.

- Maintain detailed records of quality control checks and report any deviations.

3. Production Output

Meet or exceed production targets while maintaining quality standards.

- Monitor production rates and adjust machine settings as necessary to optimize output.

- Collaborate with other team members to ensure smooth production flow.

4. Safety and Hygiene

Adhere to all safety regulations and maintain a clean and hygienic work environment.

- Follow proper lockout/tagout procedures to prevent accidents and injuries.

- Maintain a clean and organized work area to minimize contamination and ensure product quality.

Interview Tips

To ace an interview for a Can Sealer position, it is crucial to prepare thoroughly. Here are some interview tips and hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s products, operations, and industry trends. This demonstrates your interest and enthusiasm for the role.

- Visit the company’s website, read industry publications, and attend relevant trade shows.

- Prepare questions about the company’s operations and future plans to show your engagement.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as machine operation, quality control, and troubleshooting. Provide specific examples of your accomplishments in these areas.

- Quantify your results to demonstrate the impact of your work, such as reducing downtime or improving production efficiency.

- Be prepared to discuss your experience with different types of can sealing machinery.

3. Demonstrate Safety and Hygiene Awareness

Stress your commitment to safety and hygiene practices. Explain how you have implemented these practices in previous roles.

- Describe your knowledge of lockout/tagout procedures and other safety protocols.

- Explain how you maintain a clean and organized work area to ensure product quality.

4. Show Enthusiasm and a Positive Attitude

Convey your enthusiasm for the canning industry and your willingness to contribute to the team. A positive attitude can make a lasting impression.

- Express your interest in the technical aspects of the job and your desire to learn and grow.

- Be friendly and approachable, and demonstrate your ability to work well with others.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Can Sealer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.